High-efficiency grinding material

A high-efficiency, abrasive technology, applied in the field of abrasives, can solve the problems of large abrasive drop, small free accumulation density, large ore particle size, etc., and achieve improved hammer crushing ability, good direction dispersion, forging and forming good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

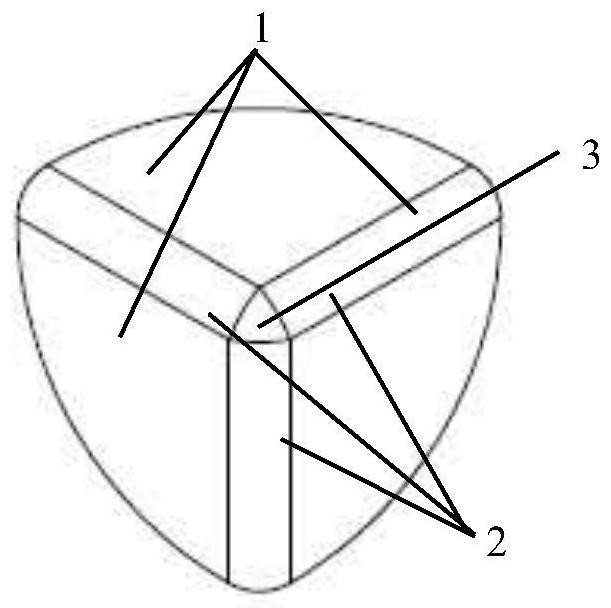

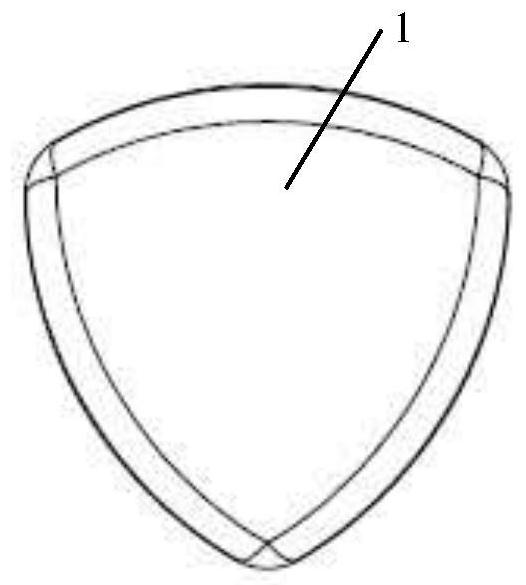

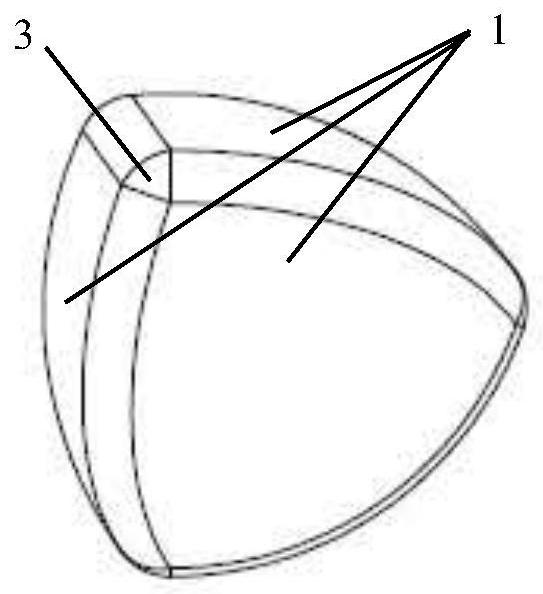

[0026] A high-efficiency abrasive, see Figure 1-8 , the invention point is: the overall shape of the abrasive is in the shape of a regular tetrahedral arc, the outer contour of the abrasive is surrounded by four equal-diameter spherical surfaces 1 according to the arrangement of the four faces of the regular tetrahedron, and the transition between two adjacent spherical surfaces The spherical surfaces 2 are smoothly connected, and the four vertices 3 are spherical vertices, and are smoothly connected with the corresponding three spherical surfaces and the corresponding three sets of transition spherical surfaces between two adjacent spherical surfaces. That is, the shape of the abrasive is similar to the regular tetrahedron s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com