Automatic sheet metal bending device

A bending device and automatic technology, applied in the field of plate bending, can solve the problems of unstable quality, inability to process large-sized sheet metal parts, low production efficiency, etc., to achieve convenience, accuracy, convenience, and convenient processing , reduce the effect of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

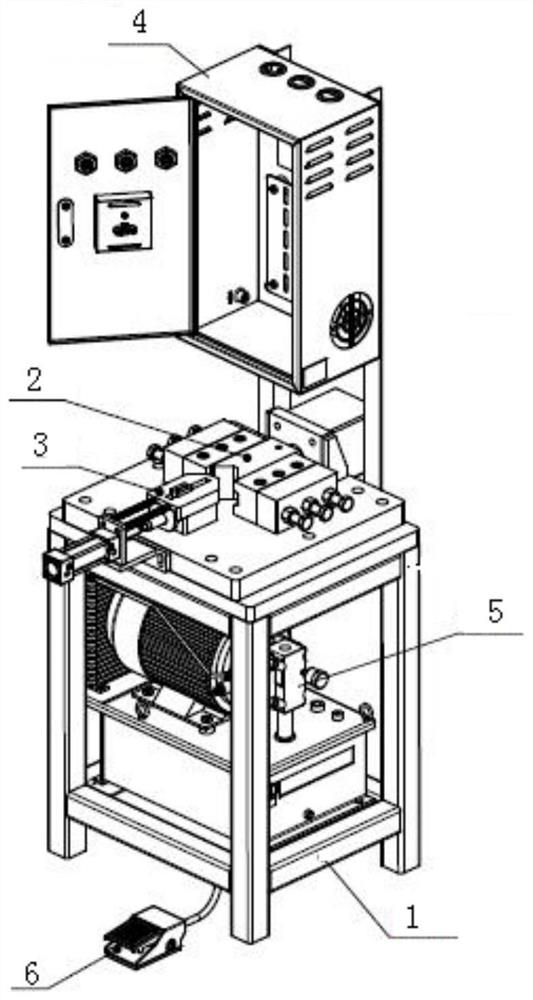

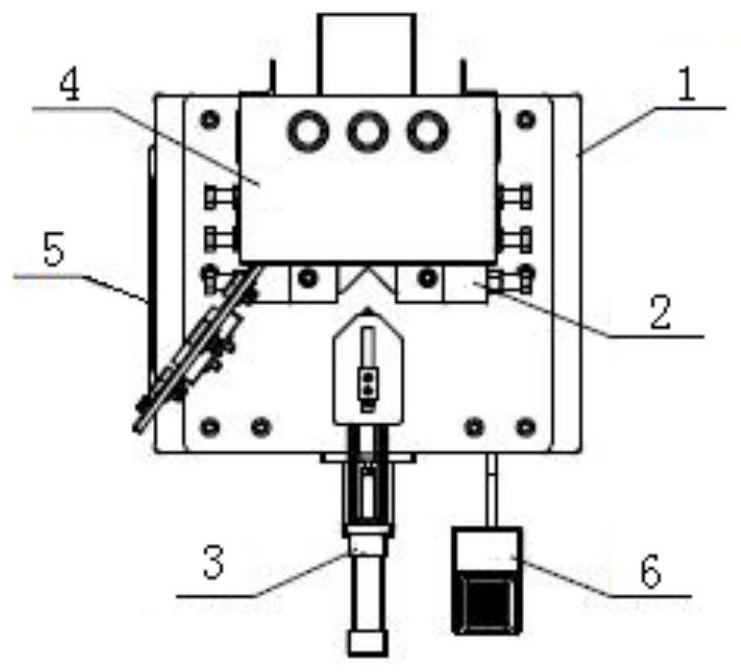

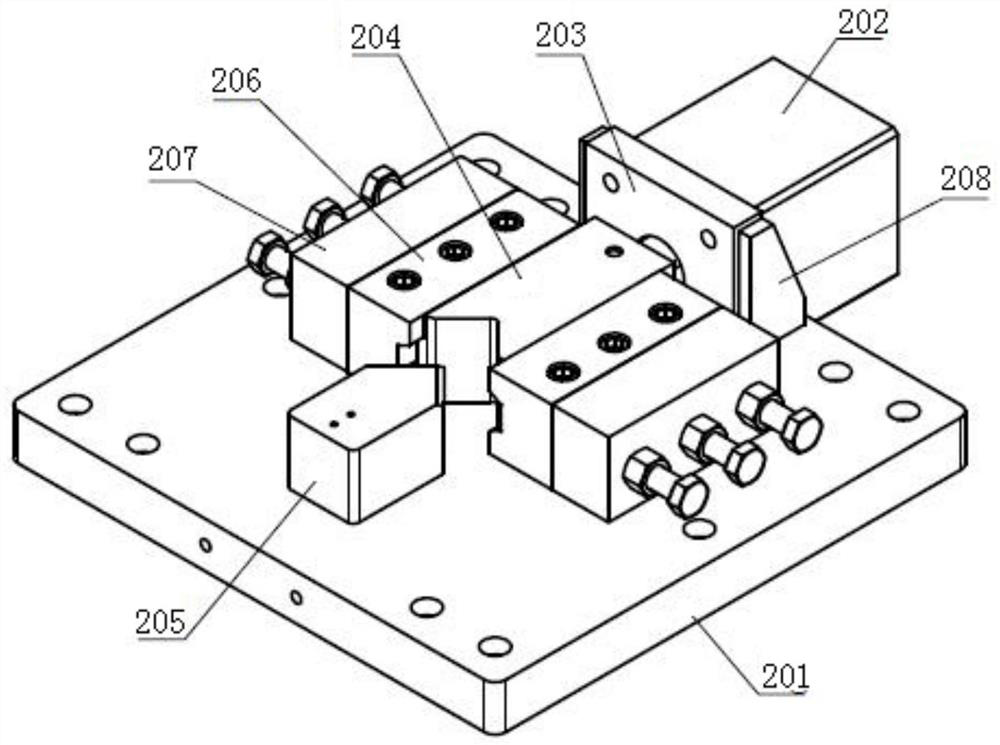

[0027] Such as Figure 1 to Figure 4 Shown is an embodiment of a sheet metal automatic bending device of the present invention. An automatic sheet metal bending device, which includes a frame 1, a bending mechanism 2, a positioning processing mechanism 3, a hydraulic station 5, an electric control box 4 and a power control switch, the positioning processing mechanism 3 and the bending mechanism 2 are located on the machine On the processing platform on the frame 1, the bending mechanism 2 and the positioning processing mechanism 3 are placed perpendicular to each other on the processing fee platform, the electric control box 4 is located on the top of the frame 1, the hydraulic station 5 is installed in the inner cavity of the frame 1, and the power supply The control switch is connected with the electric control box 4, and the electric control box 4 controls the positioning processing mechanism 3, the hydraulic station 5 and the bending mechanism 2 and provides power, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com