Flat copper wire stator welding end welding quality detection and evaluation system method

A welding quality and evaluation system technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the service life of the motor, overheating, and inconspicuous welding defects, ensuring consistency and avoiding false welding. , to ensure the effect of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

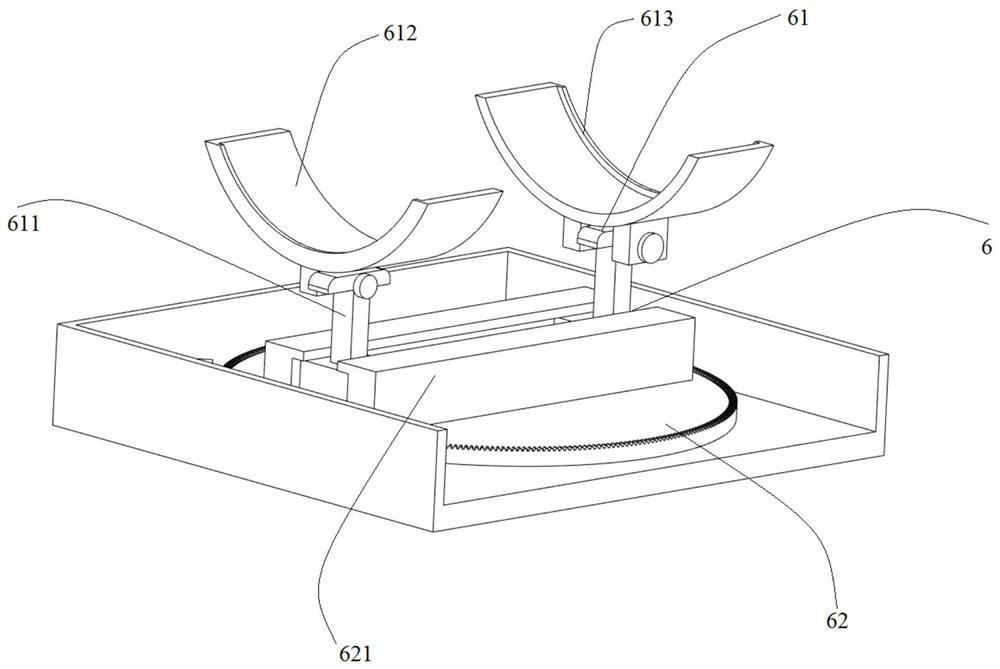

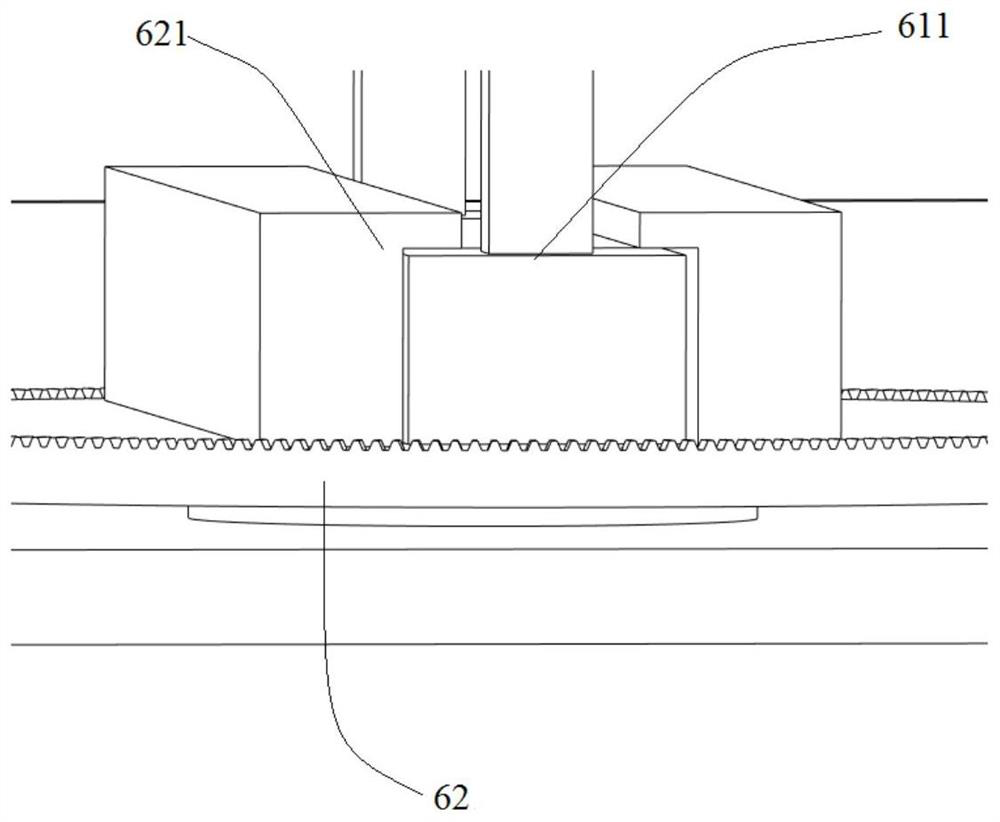

[0027] as attached Figure 1-2 : Flat copper wire stator welding end welding quality inspection and evaluation system method, including the following methods: flat copper wire winding three-phase resistance detection, flat copper wire winding energized current detection and three detection and evaluation methods for flat copper wire winding welding thermal imager detection . Through these three detection and evaluation methods, the welding quality of the flat copper wire can be inspected from multiple aspects and the quality after welding can be judged, and the welding defects in the flat copper wire welding can be found in time, which is beneficial to the detection of the stator winding and ensures the quality of the product. my stability

[0028] The method steps of the three-phase resistance detection of the flat copper wire winding are as follows:

[0029] (1) U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com