Medical instrument disinfection pretreatment device

A pretreatment device and medical device technology, applied in the field of medical devices, can solve problems such as infection of operators, splashing of medicinal liquid, and fatigue of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

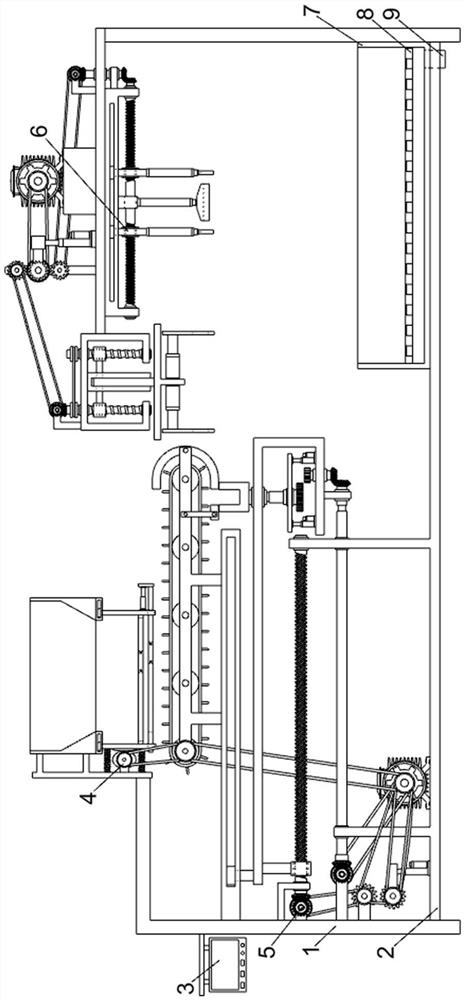

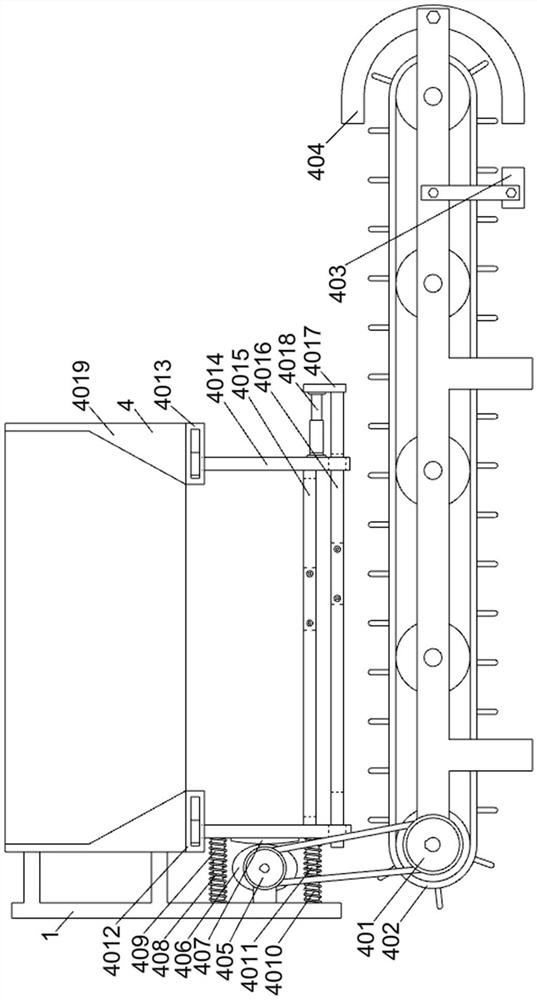

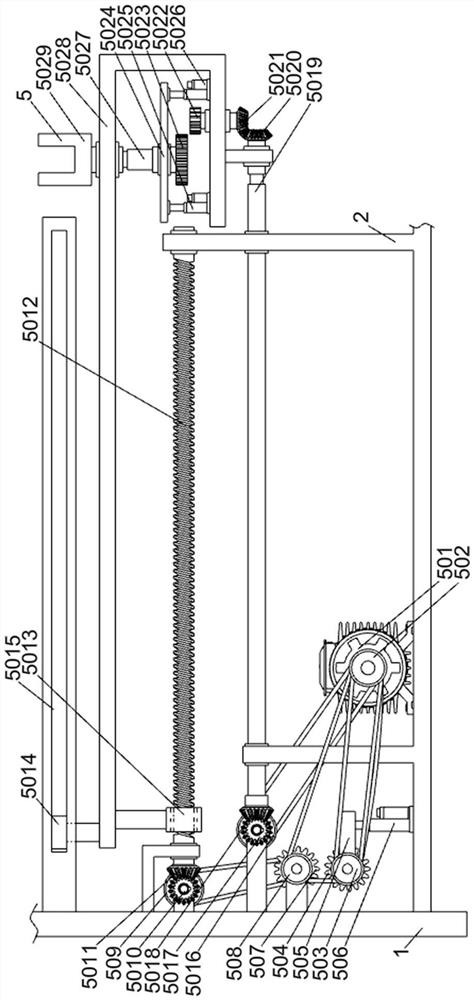

[0024] A medical equipment disinfection pretreatment device, such as Figure 1-5 As shown, it includes a working frame plate 1, a supporting chassis 2, a control display screen 3, an automatic feeding mechanism 4, a position adjustment mechanism 5, a separation mechanism 6, a material storage compartment 7, a filter screen 8 and a liquid outlet 9; The frame plate 1 is welded with the support base frame 2; the side of the work frame plate 1 is connected with the control display screen 3 through the support seat; the work frame plate 1 is connected with the automatic feeding mechanism 4; the work frame plate 1 is connected with the position adjustment mechanism 5 connection; the working shelf plate 1 is connected with the separation mechanism 6; the support chassis 2 is connected with the position adjustment mechanism 5; the storage compartment 7 is arranged above the support chassis 2; the support chassis 2 is connected with the liquid outlet 9; the storage The inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com