Rapeseed oil pressing device

An oil pressing device and rapeseed technology, which is applied in the production of fat oil/fat, fat production, presses, etc., can solve problems such as unclean pressing, and achieve the effects of reducing blockage, reducing manual labor, and reducing manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

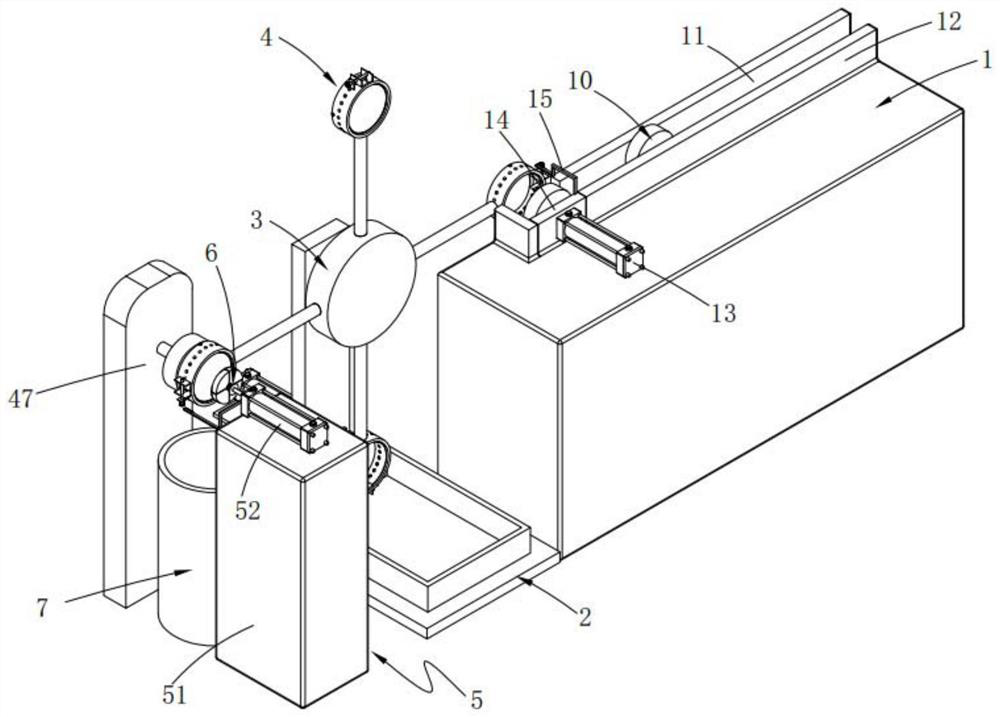

[0063] like figure 1 Shown, a kind of rapeseed oil extraction device, it comprises conveying mechanism 1, and described conveying mechanism 1 conveys rapeseed cake 10, and it also comprises:

[0064] A first base 2, the first base 2 is arranged on one side of the conveying mechanism 1;

[0065] A rotating disk 3, which is rotatably arranged on the first base 2;

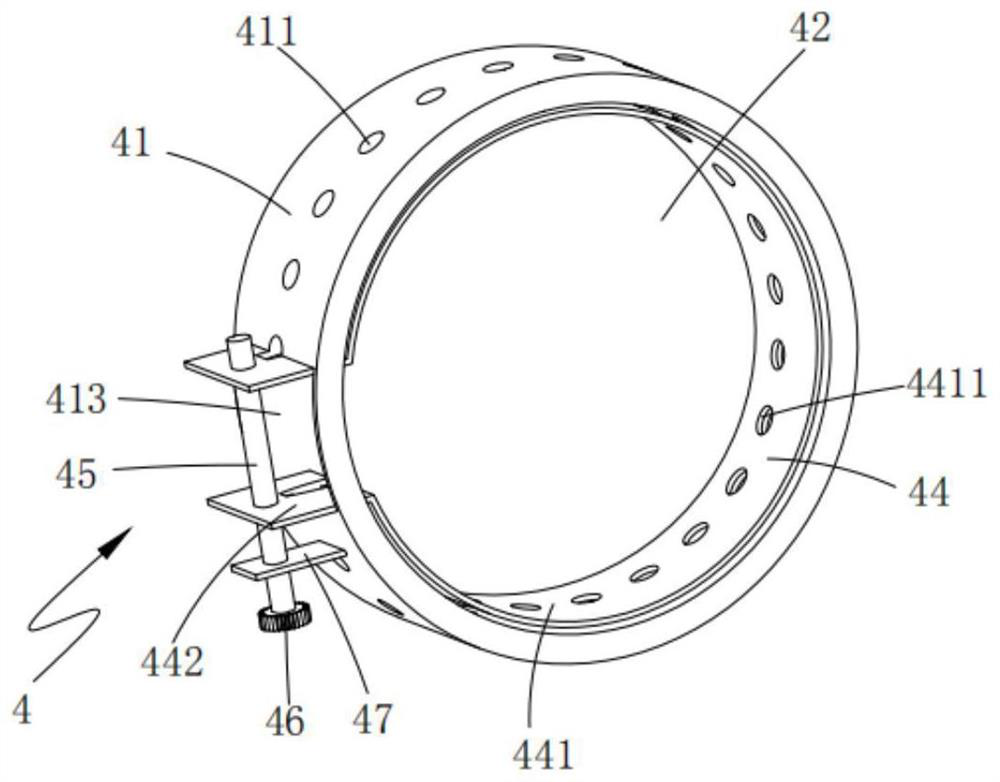

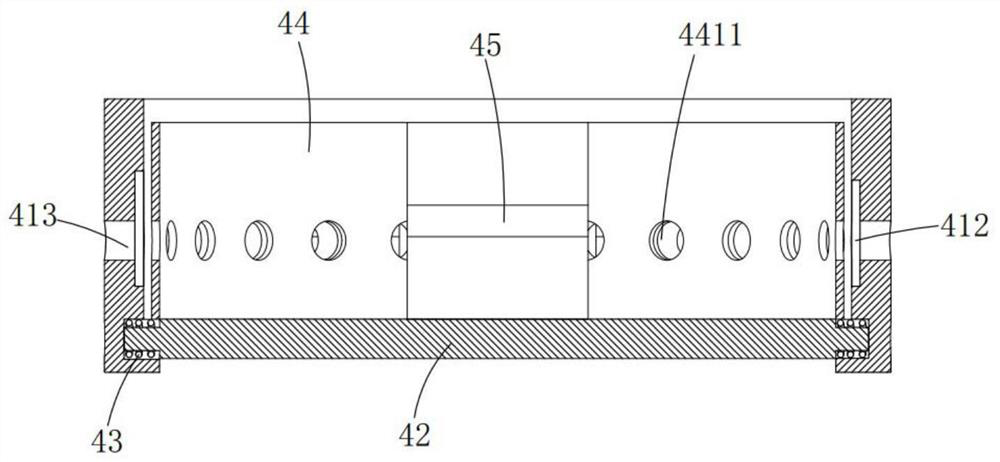

[0066] The carrying mechanism 4, the carrying mechanism 4 is arranged along the circumferential array of the rotating disk 3, and the carrying mechanism 4 rotates synchronously with the rotating disk 3, and the position of the carrying mechanism 4 corresponding to the output end of the conveying mechanism 1 is to receive station, and it corresponds to the receiving station, the oil pressing station and the discharging station in turn along the rotation direction of the rotating disk 3;

[0067] A support mechanism 5, the support mechanism 5 is arranged on one side of the first base 2, it points to the oil extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com