High-speed removing system

A high-speed, rejecting device technology, applied in the field of visual inspection, can solve problems such as inability to accurately reject products and secondary damage to products, and achieve the effect of avoiding inability to accurately reject defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

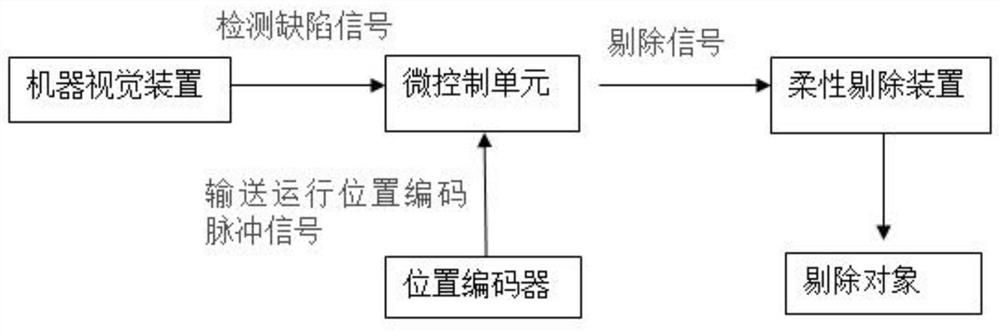

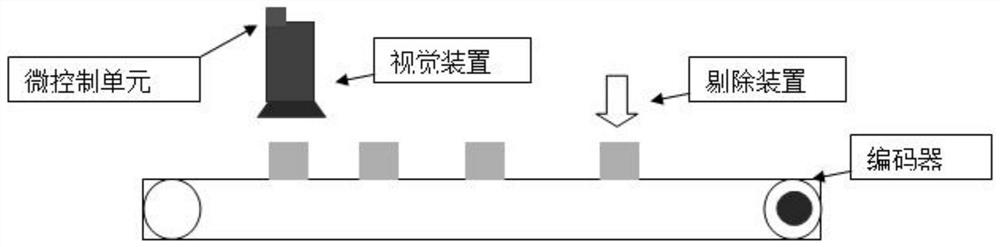

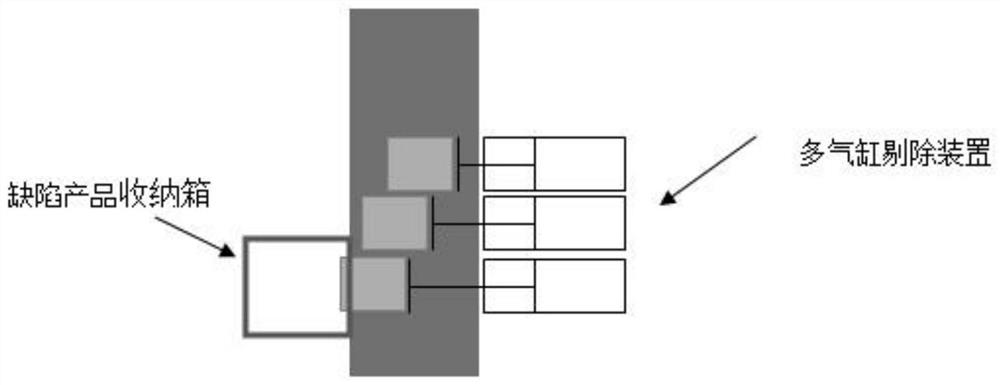

[0024] A high-speed rejecting system, comprising a control box with a micro-control unit inside, a conveying line connected to the control box, a position encoder, a visual device, a rejecting device, and a defective product storage box used in conjunction with the rejecting device, wherein the The control box is connected with the industrial computer, the position encoder is installed on the shaft of the conveying line, the vision device is installed directly above the conveying line, and the rejecting device is installed on the conveying line and at the rear of the vision device.

[0025] In this embodiment, the visual device includes a visual inspection box, and an industrial camera, an industrial lens, and a visual light source are arranged in the visual inspection box, and the visual light source includes a coaxial light source, a dome light source, and a ring light source.

[0026] In this embodiment, the rejecting device includes a cylinder box connected to the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com