Glass bar softening furnace and softening method capable of effectively reducing energy consumption

A glass rod and softening furnace technology, which is applied in the field of softening furnaces, can solve the problems such as the inability to make full use of the internal space of the high-temperature furnace, the limited number of clamps, and the necessity of shutting down for maintenance, so as to reduce the unnecessary heat loss, the replacement is simple and convenient, and the electric energy is saved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

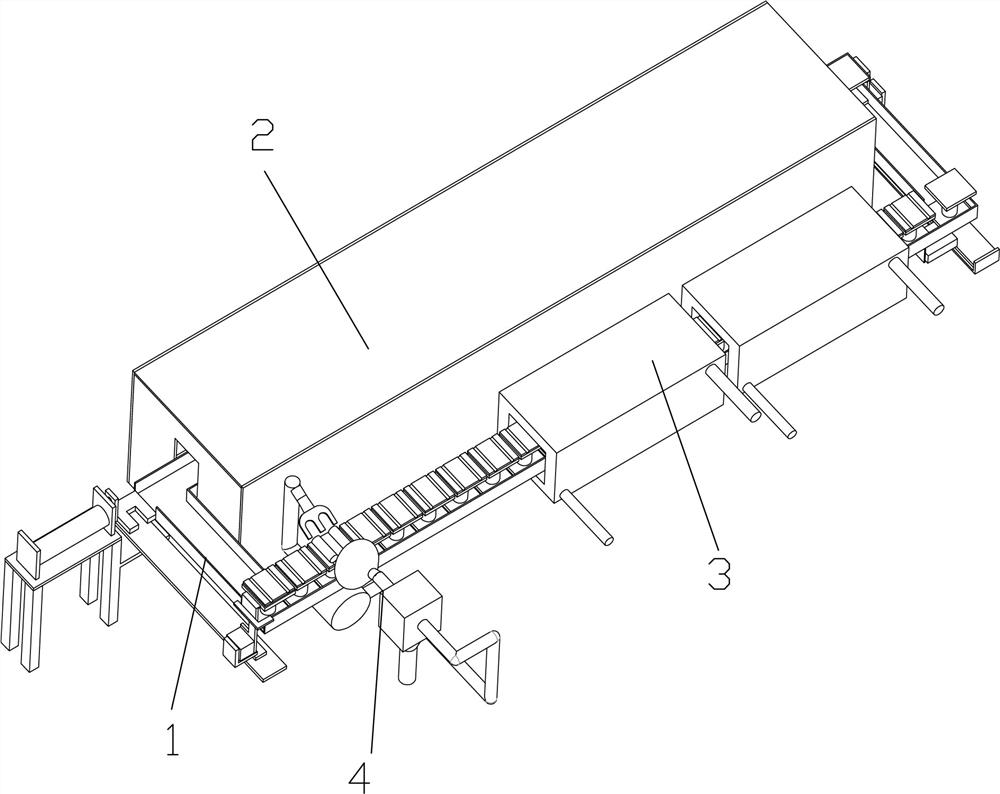

[0048] Such as figure 1 As shown, a glass rod softening furnace that effectively reduces energy consumption includes a circulation conveying mechanism 1 , a furnace body 2 , a cooling mechanism 3 and a dust removal mechanism 4 .

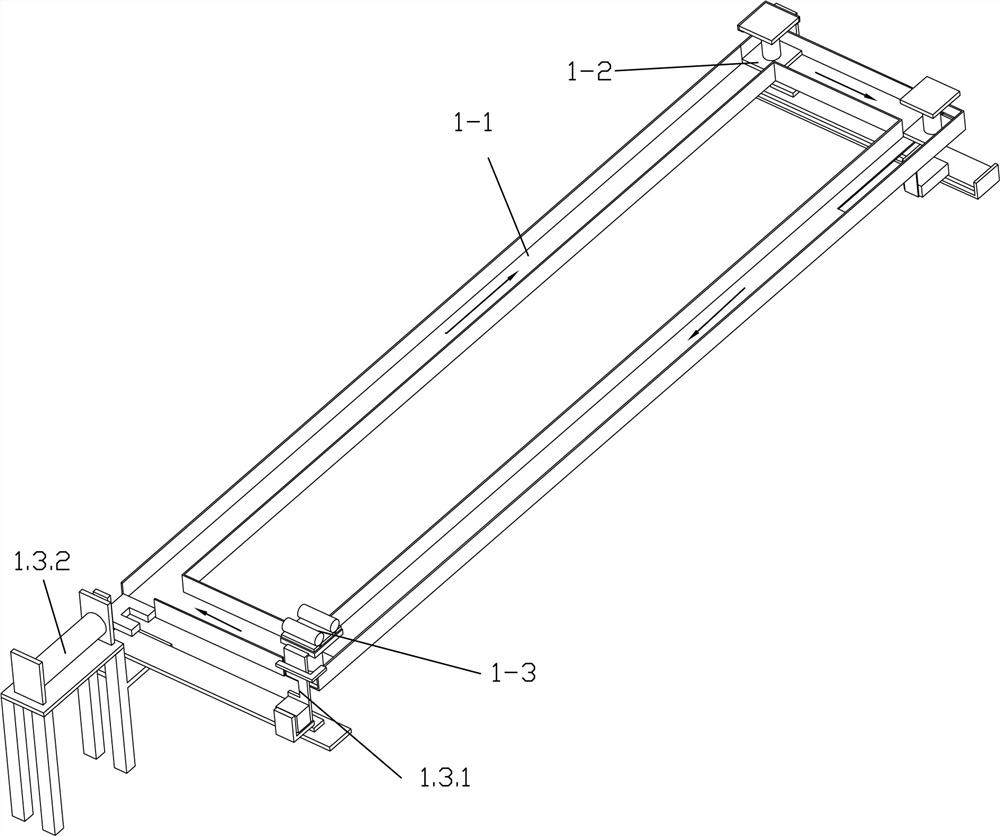

[0049] Such as figure 2 As shown, the circular conveying mechanism 1 includes a circular track 1-1, a tray 1-2 and a pushing mechanism 1-3.

[0050] The cross section of the circular track 1-1 is a U-shaped groove, the width of which is consistent with the bottom plate 1.2.1 of the tray 1-2, and is used for placing the tray 1-2.

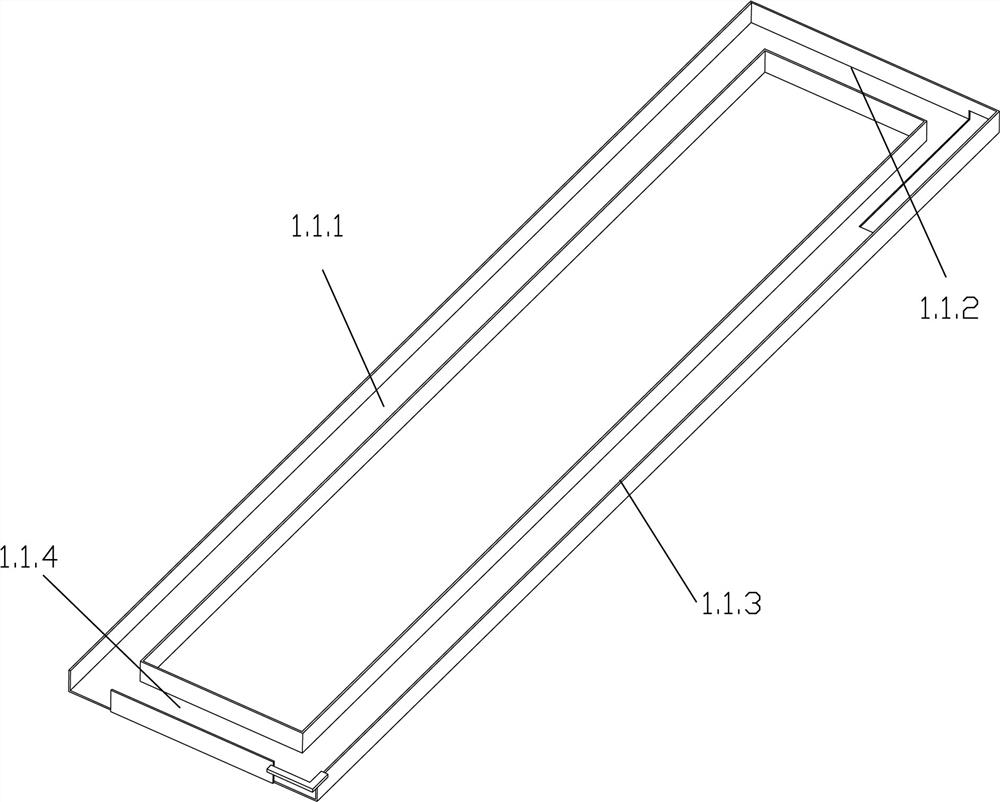

[0051] Such as image 3 As shown, the circular track 1-1 includes softening section 1.1.1, discharging section 1.1.2, cooling section 1.1.3 and feeding section 1.1.4, softening section 1.1.1, discharging section 1.1.2, cooling section 1.1.3 and feed section 1.1.4 end-to-end connection.

[0052] Wherein, the softening section 1.1.1 and the cooling section 1.1.3 are parallel and long, and N sets of trays 1-2 are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com