Pavement residue cleaning device for road maintenance

A technology for cleaning devices and residues, used in road cleaning, cleaning methods, construction, etc., can solve the problems of slow residues, dust easily scattered everywhere, etc., and achieve the effect of preventing floating everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

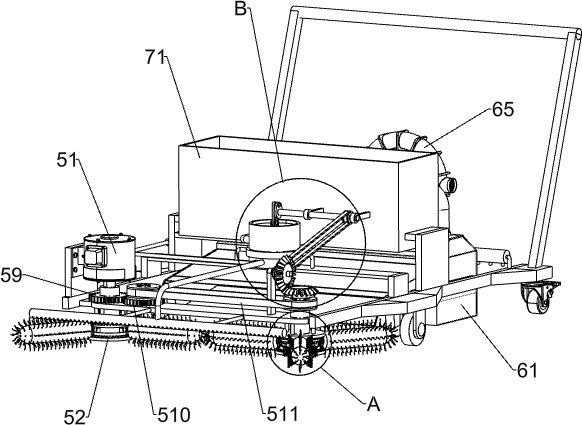

[0023] A road surface residue cleaning device for road maintenance, such as Figure 1-5 As shown, it includes a mounting frame 1, wheels 2, universal wheels 3, a hand push rod 4, a cleaning mechanism 5 and a collecting mechanism 6. Two wheels 2 are connected to the bottom of the mounting frame 1, and the two wheels 2 are left and right symmetrical. The wheels 2 The mounting frame 1 bottom of the rear is connected with universal wheel 3, and the rear side of mounting frame 1 top is connected with push rod 4, and sweeping mechanism 5 and collection mechanism 6 are respectively installed on mounting frame 1.

[0024] The cleaning mechanism 5 includes a servo motor 51, a rotating toothed disc 52, a fixed toothed disc 53, a brush tube 54, a coupling gear 55, a limit ring 56, a fixed rod 57, a fixed plate 58, a first gear 59, a second gear 510 and The first drive belt set 511, the left side of the mounting frame 1 front portion is equipped with a servo motor 51, the fixed plate 58 i...

Embodiment 2

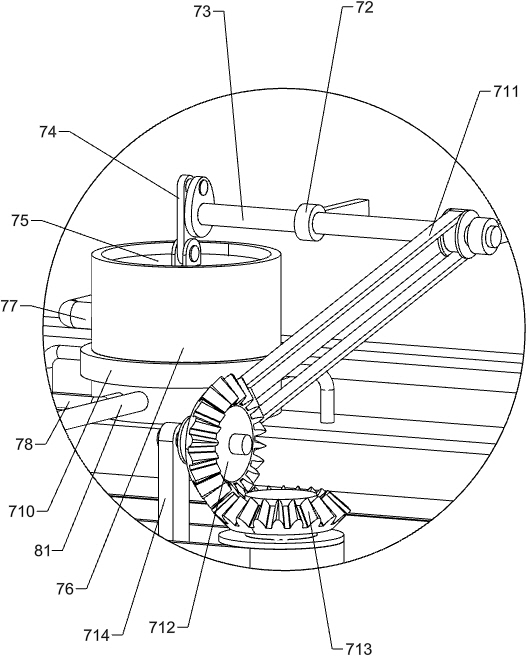

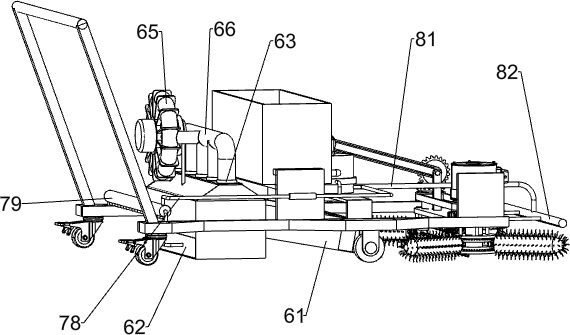

[0028] On the basis of Example 1, such as Figure 1-3 and Figure 6As shown, a flushing mechanism 7 is also included, and the flushing mechanism 7 includes a water tank 71, a fixed ring sleeve 72, a rotating shaft 73, a connecting rod 74, a pressurizing piston 75, a pressurizing barrel 76, a one-way water inlet pipe 77, a first one-way Outlet pipe 78, water spray pipe 79, fixed frame 710, second transmission belt group 711, first bevel gear 712, second bevel gear 713 and fixed block 714, the mounting frame 1 on the front side of suction barrel 61 is connected with water tank 71, two fixed rings 72 are connected to the front side of the water tank 71, and a rotating shaft 73 is rotatably connected between the two fixed rings 72. Rod 74, the mounting frame 1 top of water tank 71 front sides is connected with fixed frame 710, is connected with pressurized bucket 76 on the fixed frame 710, is connected with pressurized piston 75 slidingly in the pressurized bucket 76, and pressur...

Embodiment 3

[0031] On the basis of Example 2, such as figure 1 , image 3 and Figure 6 As shown, a dust suppression structure 8 is also included. The dust suppression structure 8 includes a second one-way water outlet pipe 81 and an atomizing nozzle pipe 82. The pressurized barrel 76 is connected with a second one-way water outlet pipe 81, and the second one-way water outlet pipe The front end of 81 is connected with an atomizing nozzle pipe 82 .

[0032] The downward movement of the pressurizing piston 75 can push the water in the pressurized barrel 76 into the atomizing nozzle pipe 82 through the second one-way water outlet pipe 81, and the water in the atomizing nozzle pipe 82 is sprayed on the road surface thereupon, so that Dust reduction is carried out to prevent the dust from flying around when the road surface is cleaned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com