Auxiliary device for controlling installation spacing of steel bars

An auxiliary device and steel bar technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of high rectification and rework rate, low construction efficiency, and high labor cost, so as to achieve a wide application range, save labor costs, and improve The effect of construction productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

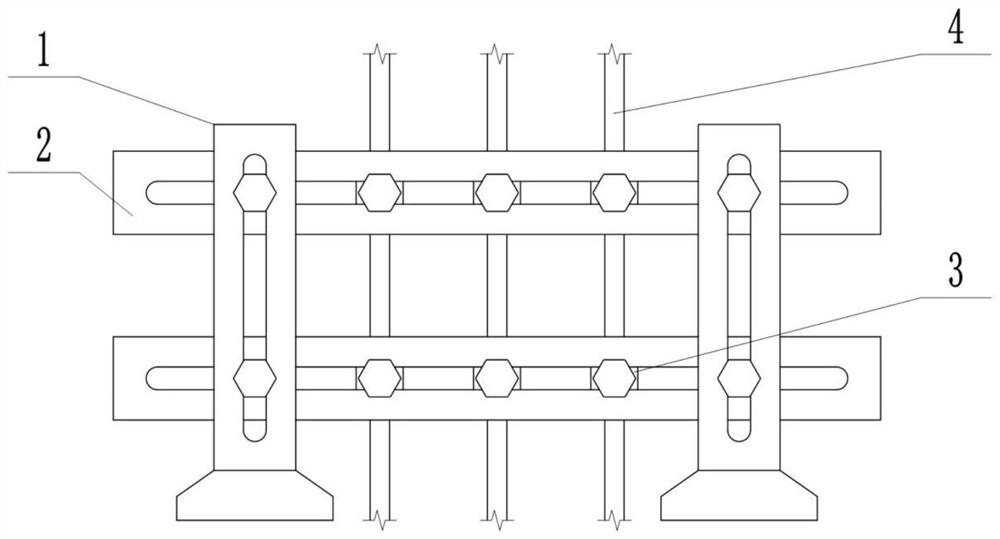

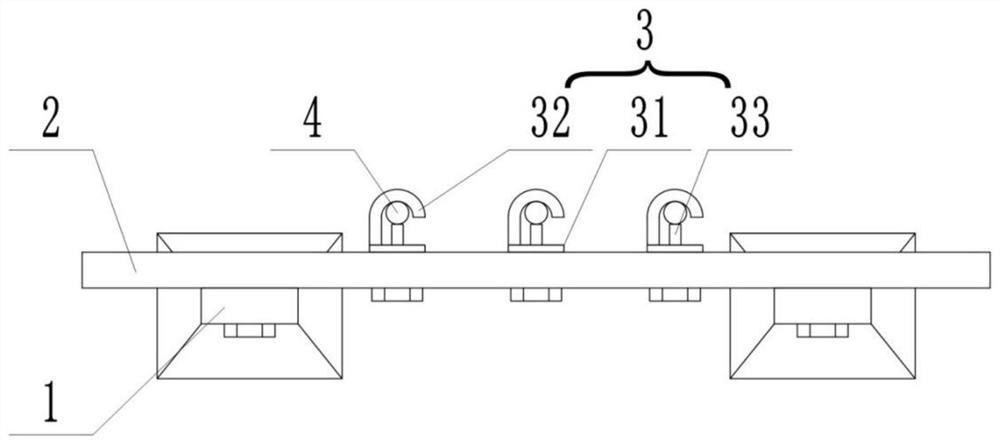

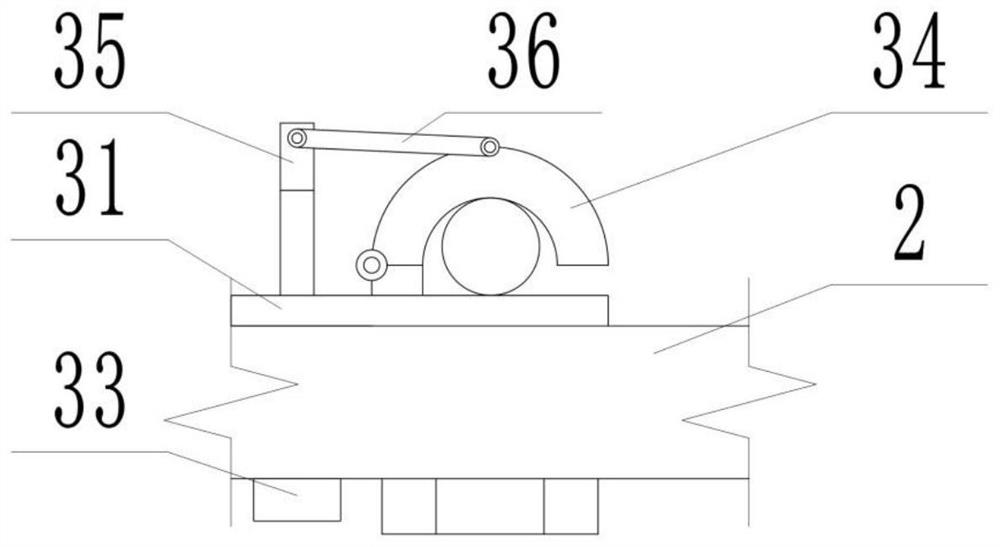

[0023] As shown in the figure, an auxiliary device for controlling the installation spacing of steel bars, including:

[0024] A plurality of columns 1, the bottom of which is supported on the ground;

[0025] Several crossbeams 2, the crossbeams 2 are fixedly connected with a plurality of columns 1 and the connection positions can be adjusted;

[0026] Several steel bar fixing units 3 are used to limit the steel bar 4. The steel bar fixing unit 3 is fixedly connected to the column 1 and / or the beam 2 and the connection position can be adjusted. The scale used to display the spacing between adjacent reinforcement fixing units 3.

[0027] Further, the crossbeam 2 and the arrangement shape of the steel bars are profilingly set.

[0028] Further, the number of beams 2 is two and arranged horizontally, and the column 1 is plugged into the supporting base.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com