A transmission tower with lead core rubber twisting and rising

A lead-core rubber and transmission tower technology, applied to towers, building types, buildings, etc., can solve problems affecting normal use, hidden safety hazards, loose transmission lines, etc., to improve safety, effective horizontal force and torsional force, The effect of reducing torsional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

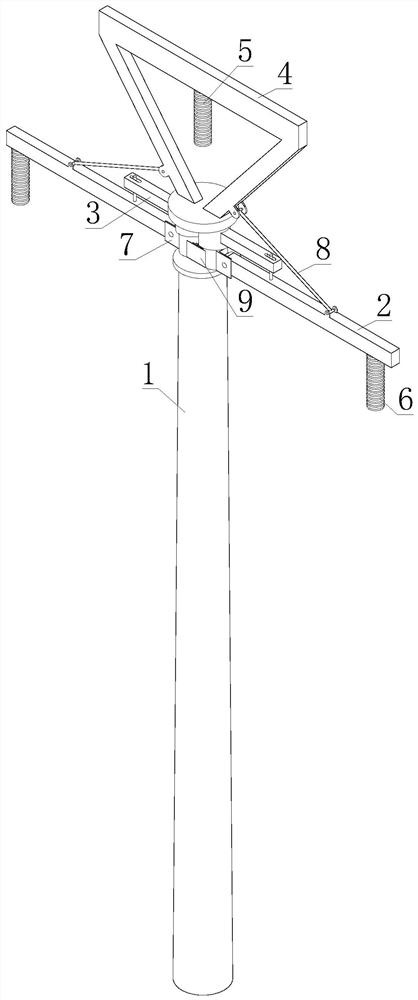

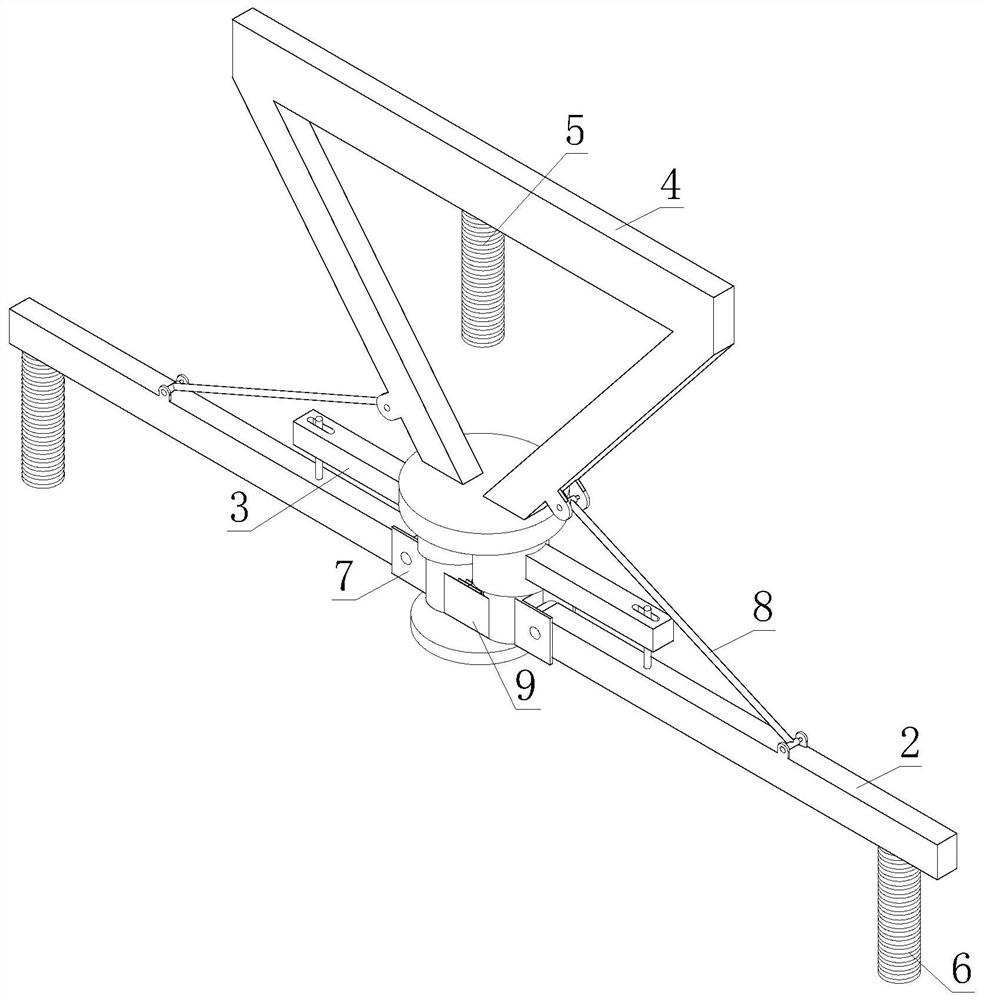

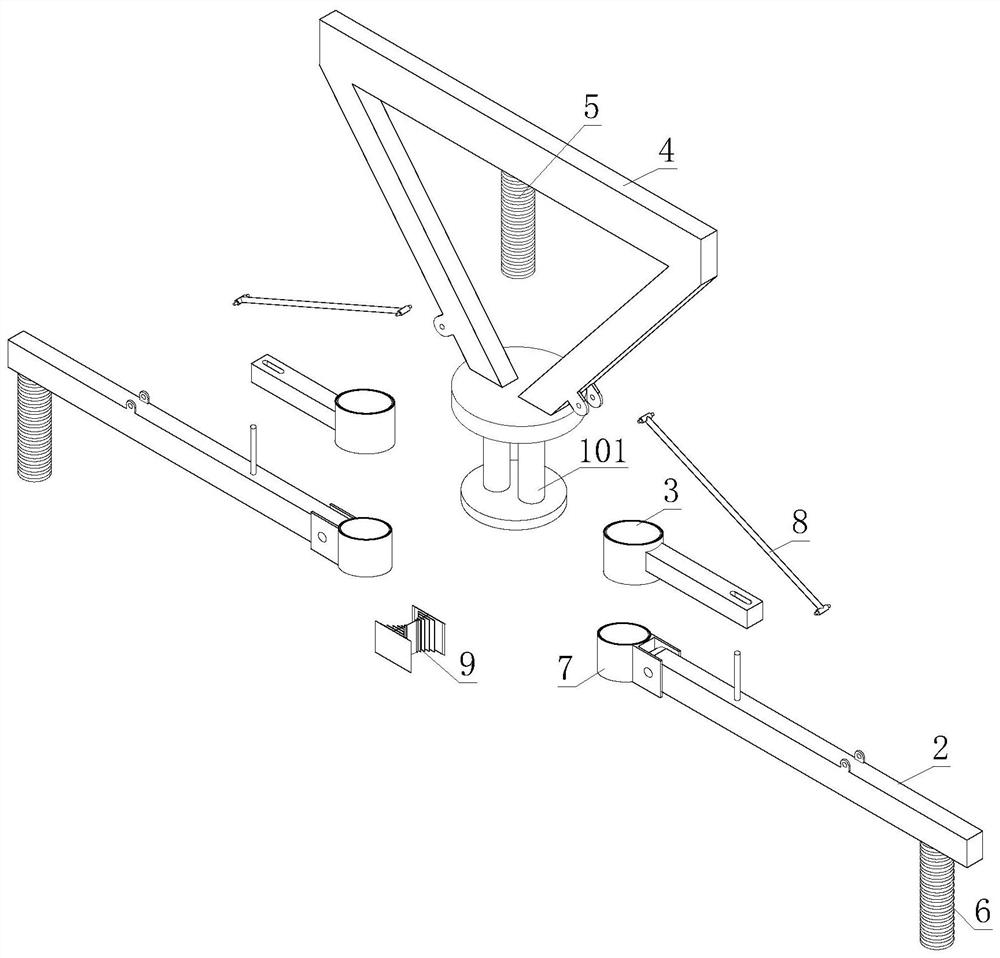

[0026] refer to Figure 1 to Figure 4 , a lead-rubber torsion-rising transmission tower, comprising a main tower 1, a low hanging point single rotating arm 2, a laminated lead rubber steel plate torsion support 3 and a high hanging point bracket 4, the main tower 1 and a high hanging point bracket 4 are fixedly connected with the main tower double rotating shaft 101, and the main tower double rotating shaft 101 is sequentially connected with the laminated lead rubber steel plate torsion support 3 and the hinge connection device 7, and the hinge connection device 7 is fixedly connected by bolts. Single swivel arm with low hanging point 2;

[0027] The main tower 1 is installed on the ground, the main tower 1 is equipped with a high hanging point support 4, the high hanging point support 4 is equipped with a high hanging point insulator 5, the high hanging point insulator 5 is connected with the high voltage transmission line, and the high hanging point support 4 It is a solid-...

Embodiment 2

[0036] refer to Figure 10 A limiter 9 is connected between two laminated lead rubber steel plate torsion bearings 3, the limiter 9 includes a longitudinal thin-walled plate 91 and a transverse thin-walled plate 92, and the vertical thin-walled plate 91 is provided with a vertical transverse thin-walled plate Wall plate 92, there is at least one set of transverse thin-walled plates 92, and each group has two pieces. The two transverse thin-walled plates 92 of the same group are symmetrical to each other about the axis of main tower 1; It abuts on the outer wall of the laminated lead rubber steel plate torsion support 3, and the remaining transverse thin-walled plates 92 ports do not abut on the laminated lead rubber steel plate torsion support 3; in normal use, the main tower 1 and A limiter 9 is set between the low-hanging-point single rotating arm 2, and the two ends of the transverse thin-walled plate 92 are abutted against the outer wall of the laminated lead rubber steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com