Nozzle governing steam turbine single valve/sequence valve undisturbed switching steam distribution curve optimization method

A nozzle adjustment and non-disturbance switching technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of increasing the switching workload and error probability of operating personnel, increasing the safety risk of steam turbine operation, and reducing the economical efficiency of steam turbine operation, etc. , to achieve the effect of improving operating economy, eliminating safety risks, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

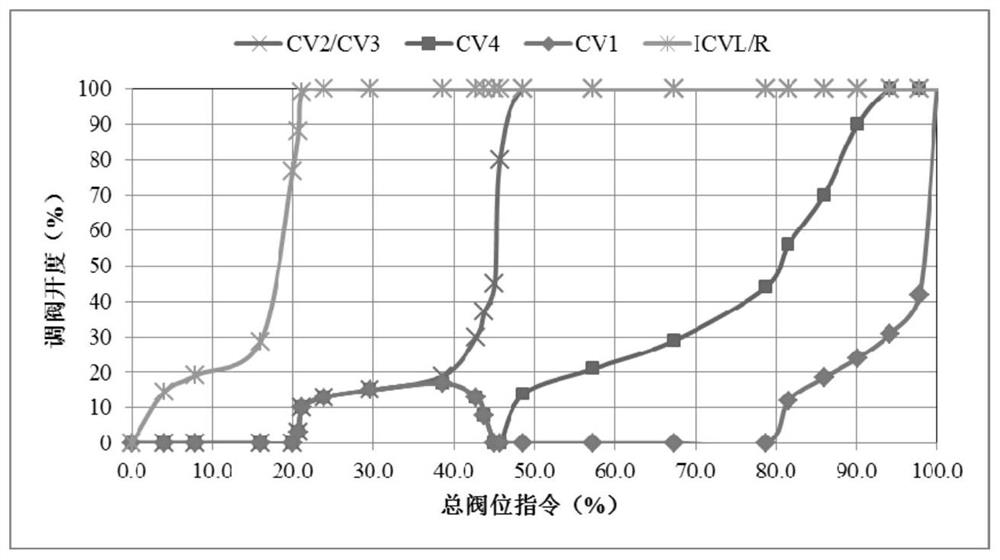

[0028] reference figure 1 , figure 1 For a 600MW supercritical nozzle to adjust the steam turbine single valve / sequence valve to switch the steam distribution curve without disturbance. The steam turbine is a medium-pressure cylinder start mode. When the total valve position command of the steam turbine is 0<MR≤20%, the openings of CV2, CV3, CV4 and CV1 are all 0, and the middle regulating valve command of the steam turbine opens gradually from 0 to 100 ; When the total valve position command of the steam turbine is 20%<MR≤39.6%, the CV2, CV3, CV4, and CV1 high-profile valves are opened synchronously, and the openings are the same. At this stage, the steam turbine distribution method is a complete single valve steam distribution method; When the total valve position command 39.6%<MR<45%, the opening of CV2 and CV3 high-profile valves continue to increase, and the CV4 and CV1 high-profile valves gradually close. At this time, the steam turbine is in the single-valve steam-to-sequ...

Embodiment 2

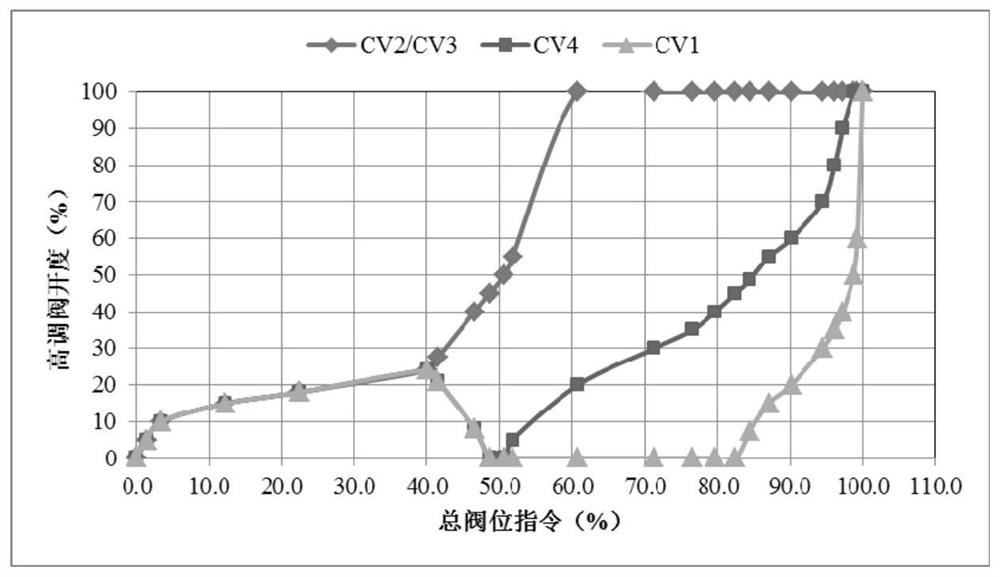

[0030] reference figure 2 , figure 2 For a 1000MW ultra-supercritical nozzle to adjust the steam turbine single valve / sequence valve non-disturbed switching steam distribution curve. When the total valve position command of the steam turbine is 0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com