Method for rapidly measuring thickness value a of weld bead

A technology for fast measurement of weld bead thickness, applied to measuring devices, instruments, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The method for fast measuring weld bead thickness a value of the present invention, its preferred embodiment is:

[0015] The root of the weld bead is used as the starting point to draw concentric circles. When the radius of the concentric circle increases to intersect with the nearest intersection point of the outer contour construction line of the weld, the radius of the concentric circle is the value a of the thickness of the weld bead.

[0016] The line connecting the center of the concentric circles to the intersection point is the theoretical weld fracture position of the weld bead, and is also the measurement position of the weld bead thickness a value.

[0017] The weld bead is symmetrical, asymmetrical or irregular.

[0018] The method for quickly measuring the a value of the weld bead thickness of the present invention adopts the concentric circle method to measure the a value of various forms of weld bead, and can quickly, accurately and conveniently determin...

specific Embodiment

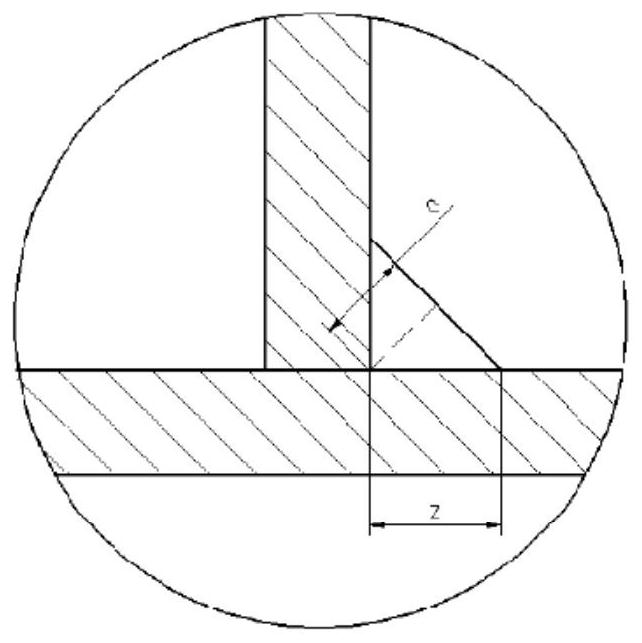

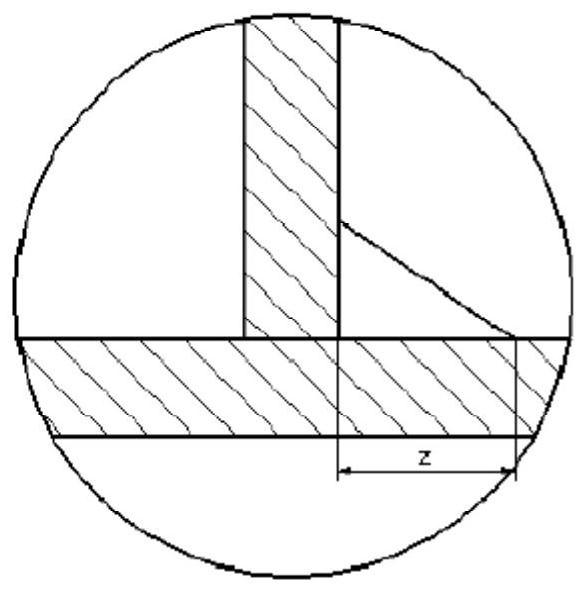

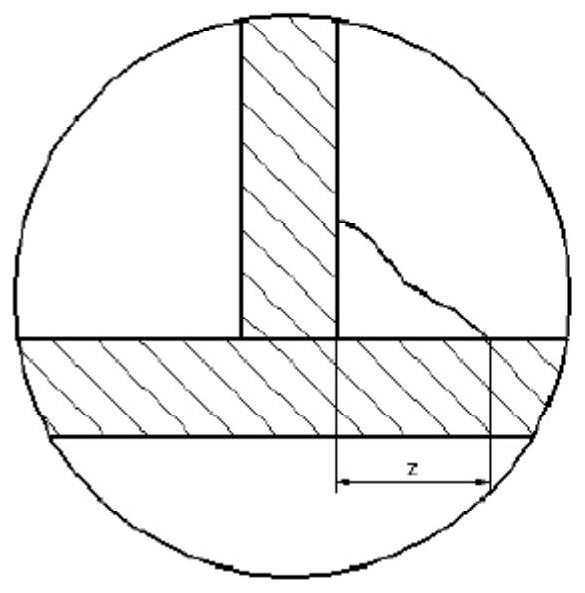

[0020] Such as Figure 3a , Figure 3b , Figure 3c As shown, according to the failure theory of weld fracture, concentric circles are drawn starting from the root of the weld bead, and terminate when the radius of the concentric circle increases to intersect with the nearest intersection point of the outer contour construction line of the weld. The radius of the concentric circle is the thickness a value of the weld bead, and the line from the center of the circle to the intersection point is the theoretical weld fracture position.

[0021] attached Figure 3a , Figure 3b , Figure 3c Two cases are given respectively in the above. In the case of the same z value, due to the occurrence of asymmetry or irregularity, it is difficult to truly reflect the actual value of a by using mathematical calculation methods. However, by adopting the concentric circle method provided by the present application, the position and size of the a value can be determined quickly and accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com