Automatic beef pickling equipment

A beef and automatic technology, applied in mixed meat equipment, meat tenderization, processed meat, etc., can solve the problems of low processing efficiency and long marinating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

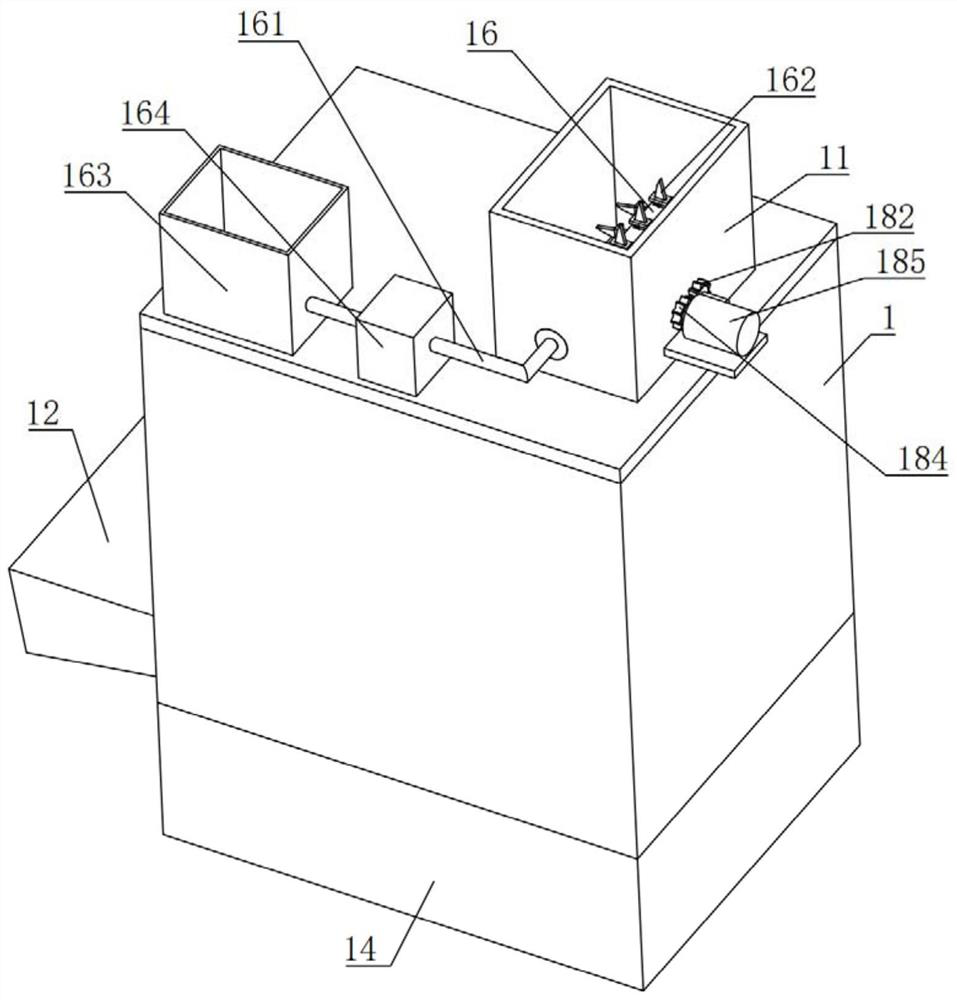

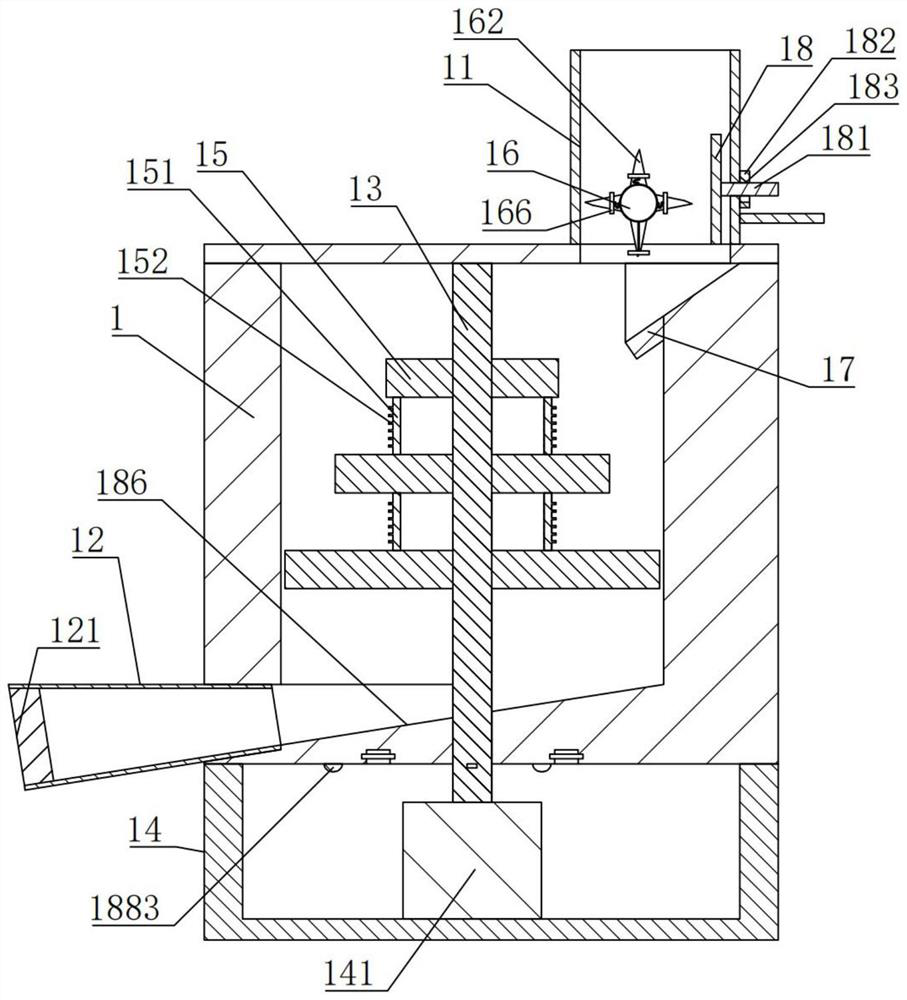

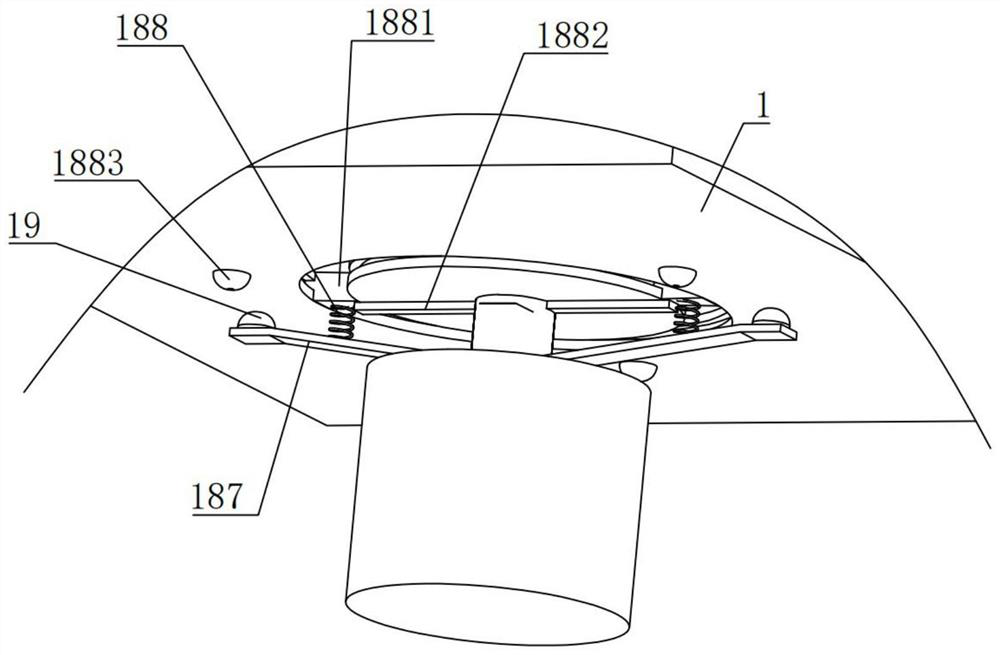

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A kind of beef automatic marinating equipment, such as figure 1 and figure 2 , including a mixing box 1, the upper end of the mixing box 1 is provided with a feed pipe 11 for the beef to be cured to enter, the cross section of the feeding pipe 11 can be square, and the lower end of the outer wall of the mixing box 1 is provided with a discharge pipe connected to the inside of the mixing box 1 Pipe 12, the outlet of discharge pipe 12 is closed by a closure, and the closure can be a closed rubber plug 121 tightly connected to the inner wall of discharge pipe 12, which is convenient for marinating the beef inside the mixing box 1. A stirring device is provided in the mixing box 1. A seasoning input device is provided in the feed pipe 11 .

[0024] Such as figure 1 and figure 2 , put the beef to be marinated into the feed pipe 11, at this time, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com