Cypress seed grinding device for incense making

A technology for making incense and cypress seeds, which is applied in the field of cypress seeds crushing devices for incense making, can solve the problems of low efficiency of cypress seeds crushing, easy fatigue of manual labor, etc., and achieves the effect of facilitating collection and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

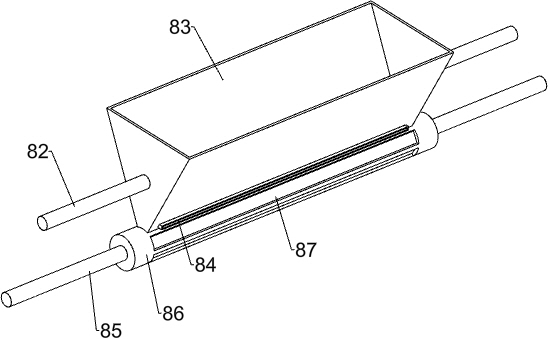

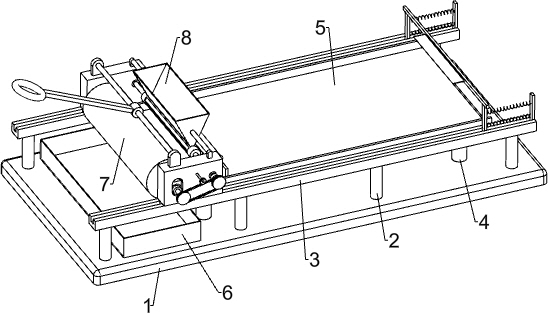

[0037] A device for crushing cypress seeds for making incense, such as figure 1 As shown, it includes a base 1, a first support column 2, a slide rail 3, a second support column 4, a backing plate 5, a collection frame 6, a rolling mechanism 7 and a blanking mechanism 8, and the front and rear sides of the top of the base 1 are uniform. Four first support columns 2 are installed, slide rails 3 are arranged between the tops of the four first support columns 2 on the front and rear sides, and a second support column 4 is arranged on the base 1 in a rectangular shape. The second support column 4 A backing plate 5 is installed on the top, and the backing plate 5 is located between the slide rails 3 on both sides, a collection frame 6 is placed on the left side of the base 1, and a rolling mechanism 7 is installed between the slide rails 3 on both sides. A blanking mechanism 8 is arranged on the part.

[0038] When the cypress seeds need to be crushed, the cypress seeds are manual...

Embodiment 2

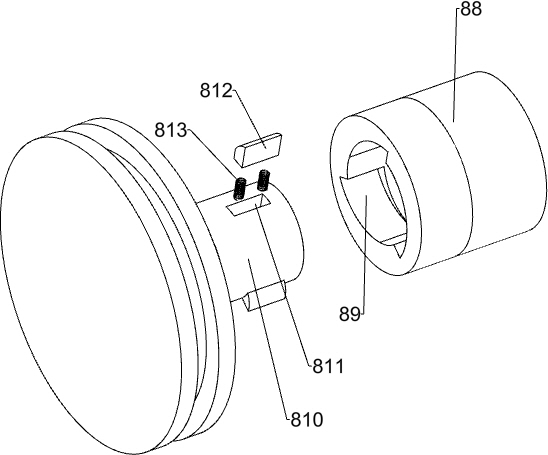

[0040] Referring to the illustrations of 2-4, the rolling mechanism 7 includes a first slide block 71, a block 72, a bearing block 73, a first elastic member 74, a first rotating shaft 75, a roller 76, a first sector block 77, a first Connecting column 78, connecting rod 79 and handle 710, all slide type is provided with first slide block 71 in the first slide rail 3 of both sides, and block 72 is installed on the top of first slide block 71, and block 72 inner left side sliding type is provided with. Bearing block 73 is arranged, the first elastic member 74 is connected between the top of bearing block 73 and the inner wall of square 72 opposite to it, the first rotating shaft 75 is all provided on the bearing block 73 on both sides, installs between the first rotating shaft 75 on both sides There is a cylinder 76, the lowest point of the cylinder 76 is lower than the height of the backing plate 5, the left side of the top of the block 72 is provided with a first fan-shaped bl...

Embodiment 3

[0045] Specifically, such as Figure 5-6 As shown, it also includes a stopper 9, a second slider 10, a connecting rod 11, a stopper 12 and a third elastic member 13, and the right side of the top of the slide rail 3 is equipped with a stopper 9, and the right side of the slide rail 3 slides The second slider 10 is provided in the formula, and a connecting rod 11 is installed between the tops of the second slider 10 on both sides. Two third elastic members 13 are connected between the parts.

[0046] When the cylinder 76 moved to the right, the slide box 84 moved right thereupon, the slide box 84 moved right and contacted the stop block 12, the stop block 12 was inserted in the slide box 84, the cypress seeds stopped falling into the groove 87, and the cylinder 76 continued Move to the right, the slide box 84 drives the stop block 12, the connecting rod 11 and the second slide block 10 to move to the right, the third elastic member 13 is compressed, and when the roller 76 move...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap