Automatic dredging device and vacuum pump for oil outlet of vacuum pump

A vacuum pump and vacuum pump technology, applied in the direction of pumps, engine components, engine seals, etc., can solve problems such as blockage of the circulating oil outlet, and achieve the effects of reducing flow resistance, facilitating installation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

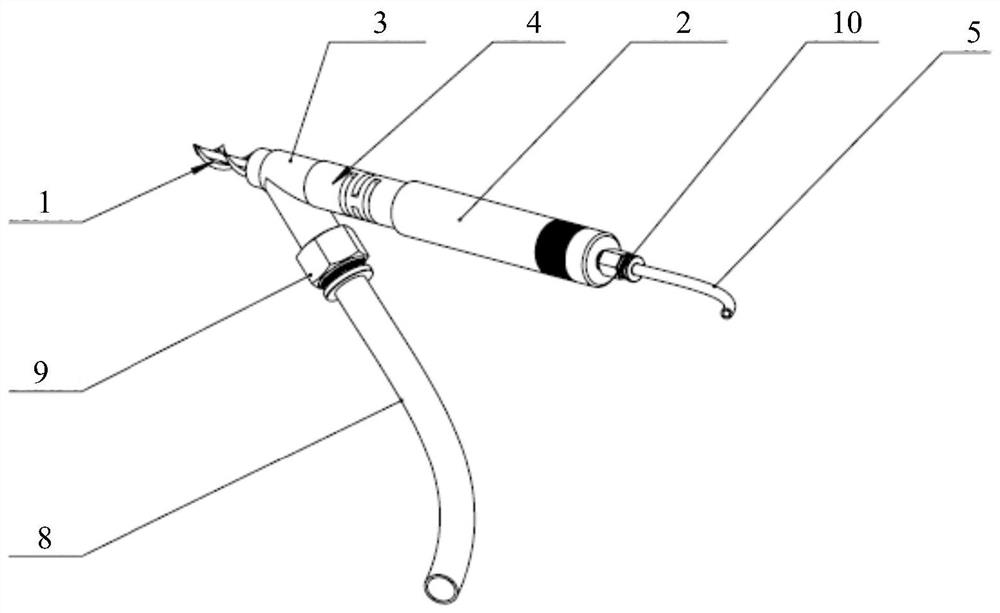

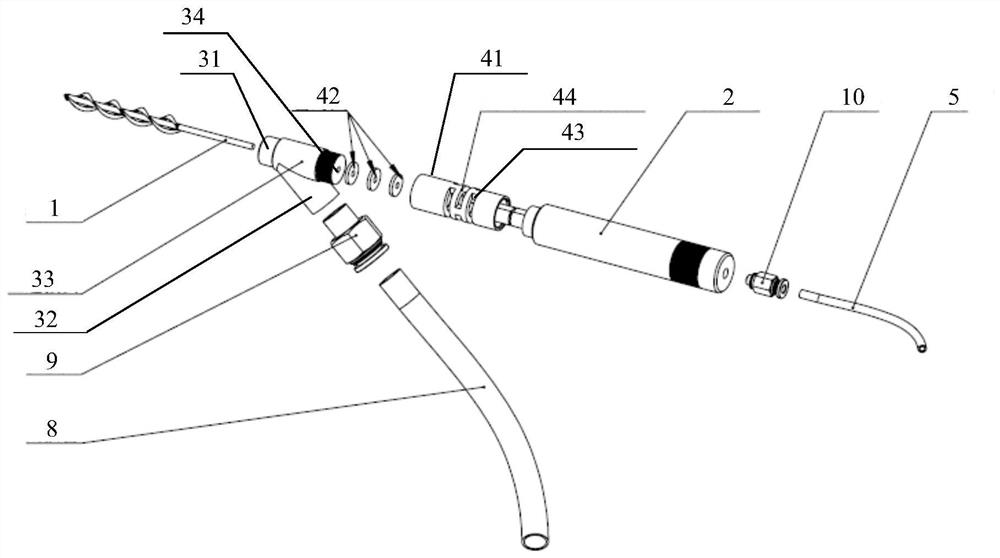

[0050] This embodiment provides an automatic dredging device for the oil outlet of a vacuum pump, see Figure 1 to Figure 5, including a stirring rod 1 and a motor 2 (for example, an air motor) that drives the stirring rod 1 to rotate, the stirring rod 1 is used to crush the solid impurities in the oil outlet, and one end of the stirring rod 1 extends through the vacuum pump oil outlet to the vacuum pump In the pump body, the other end is connected to the output end of the motor 2, and the motor 2 is used to provide rotational power for the stirring rod 1.

[0051] During implementation, turn on the motor 2, the output end of the motor 2 rotates, and then drives the stirring rod 1 to rotate, and the rotating stirring rod 1 crushes the solid impurities in the connection between the vacuum pump oil outlet and the vacuum pump body and the vacuum pump oil outlet and then discharges them.

[0052] Compared with the prior art, the automatic dredging device for the oil outlet of the ...

Embodiment 2

[0073] This embodiment provides a vacuum pump, see Figure 6 , which includes a vacuum pump body 7, a vacuum pump oil outlet 6 connected to the vacuum pump body 7, and an automatic dredging device located at the vacuum pump oil outlet 6. The automatic dredging device is used for the vacuum pump oil outlet provided by Embodiment 1 automatic dredging device.

[0074] Exemplarily, the above-mentioned vacuum pump is an oil-sealed vacuum pump, for example, a stationary vane vacuum pump, a rotary vane vacuum pump, a slide valve vacuum pump or a trochoidal vacuum pump.

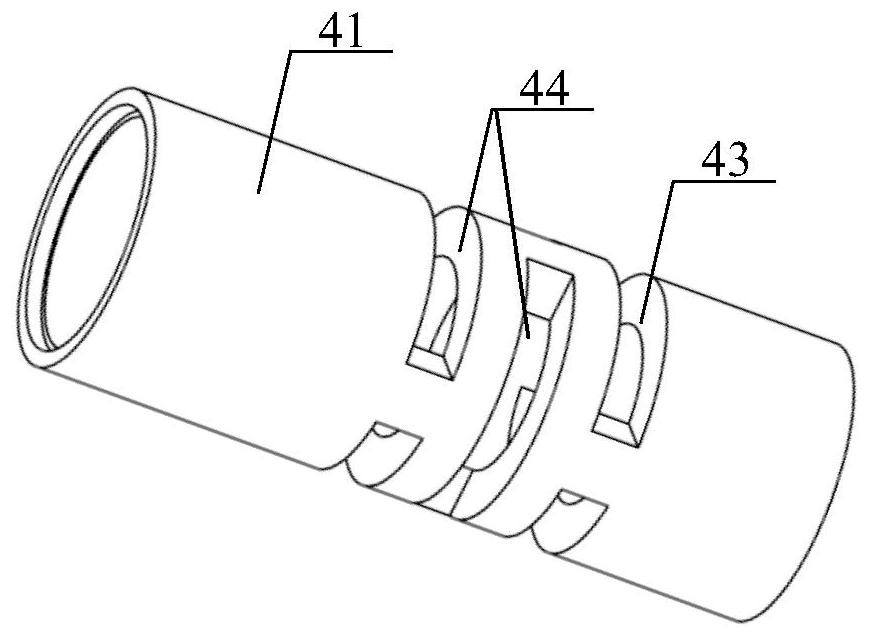

[0075] In order to promote the disturbance of the oil in the oil outlet 6 of the vacuum pump and increase the contact probability of solid impurities with the stirring rod 1, the inner wall of the oil outlet 6 of the vacuum pump is set in a spiral structure, and the oil flows in the spiral oil outlet, and the disturbance itself is relatively small. Large, so that the probability of contact between the solid impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com