A computer radiator automatic welding robot

An automatic welding and radiator technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to form linkage effects, inability to weld tower radiators, and many power structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

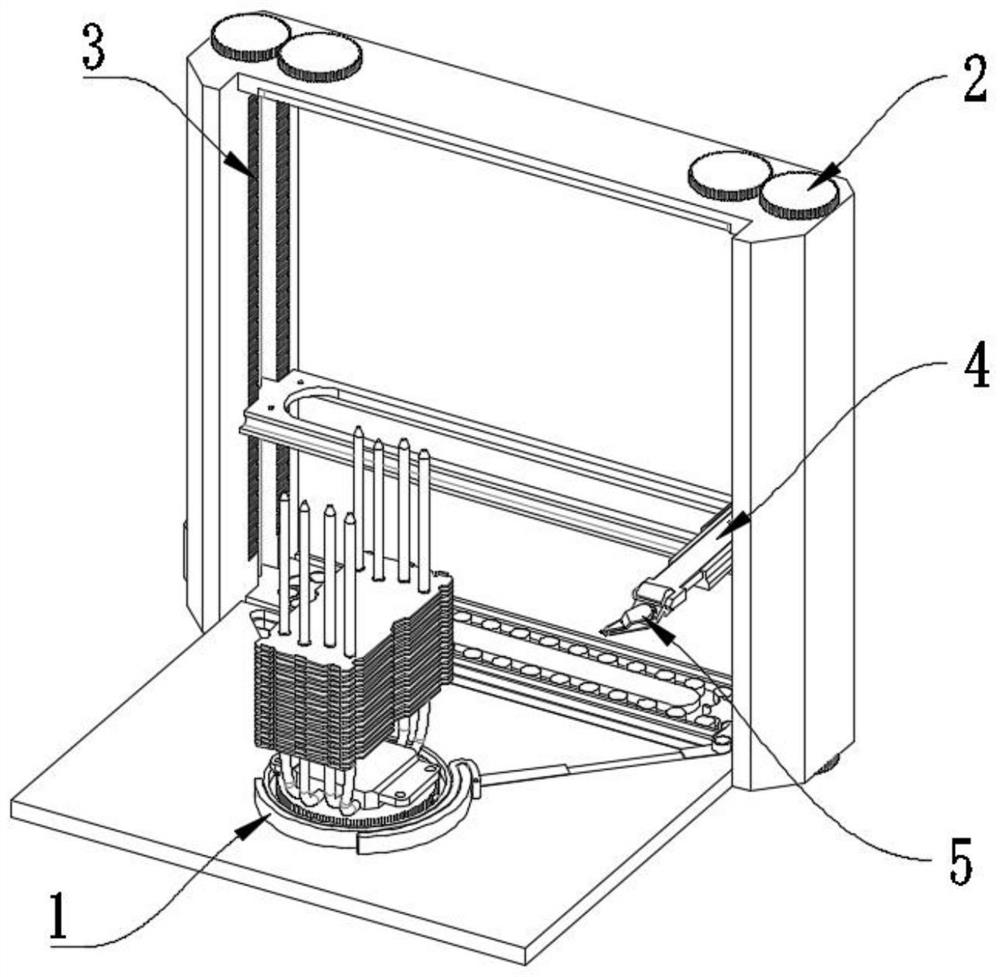

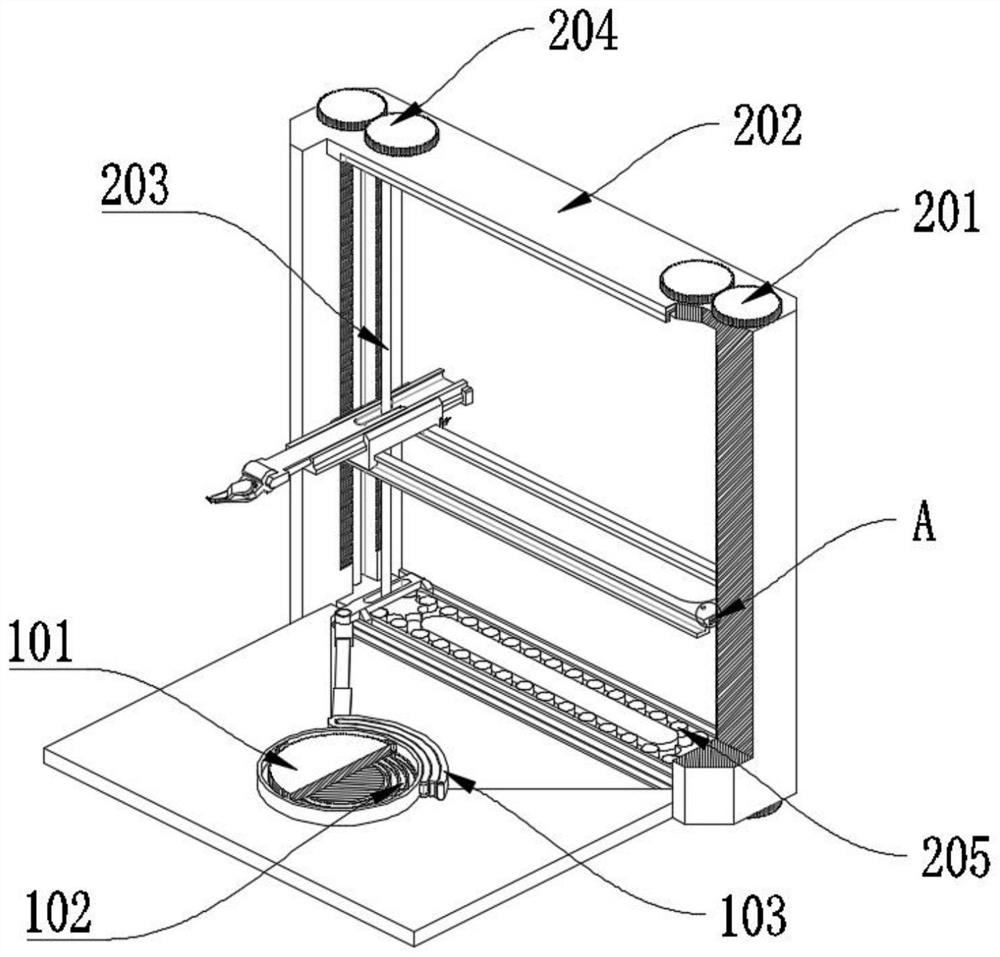

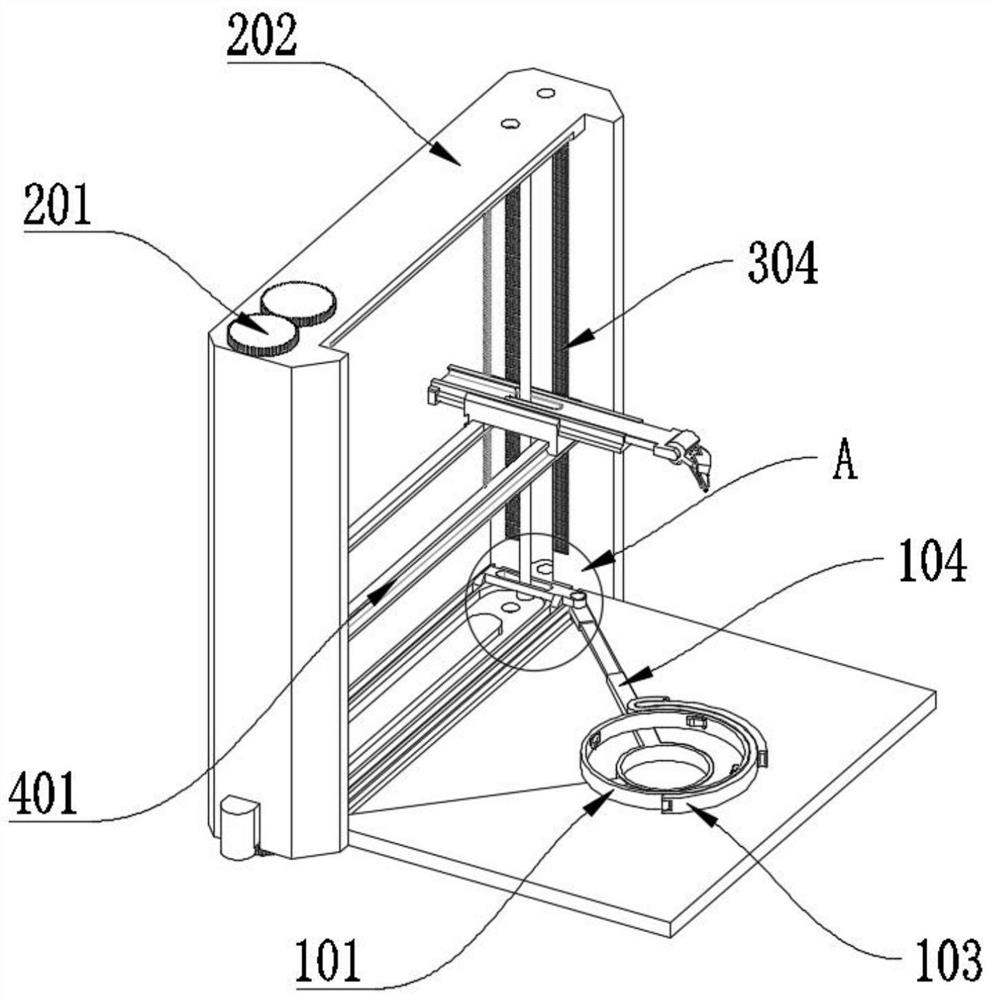

[0040] as attached figure 1 to attach Figure 13 Shown:

[0041] The present invention provides an automatic welding robot for computer radiators, which includes an installation structure 1; the installation structure 1 is connected and driven through the transmission structure 2 on the rear side, and the whole swing rod 104 is in a state of being able to expand and contract arbitrarily, and at the same time, the bottom slider is slidably installed The bottom chute 106 of 105 is two parallel places, and the bottom slide block 105 is provided with a through waist round groove, and the waist round groove provided on the bottom slide block 105 is sleeved and fixed with a connecting shaft 203, and the bottom slide The block 105 is installed through two parallel bottom chute 106, and the connecting shaft 203 of the device is in a state of continuous motion, so that the whole bottom slider 105 completes a stable and balanced swing back and forth in the bottom chute 106 under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com