Antiskid step for machine tool

A step, anti-skid technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inconvenient cleaning, easy to fall, reduce friction, etc., to facilitate centralized cleaning and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

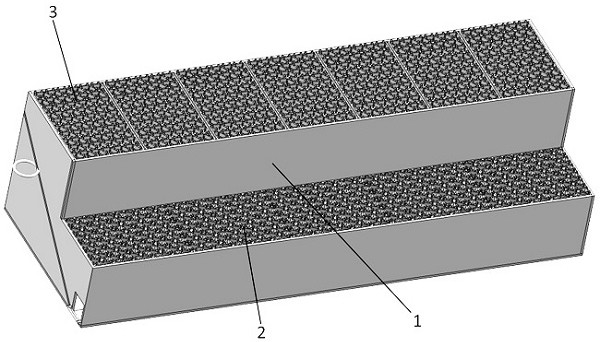

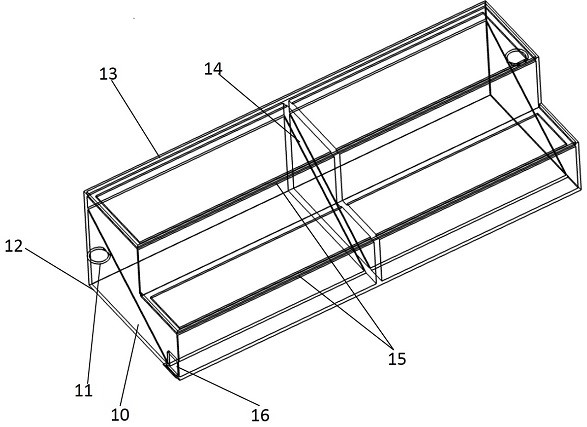

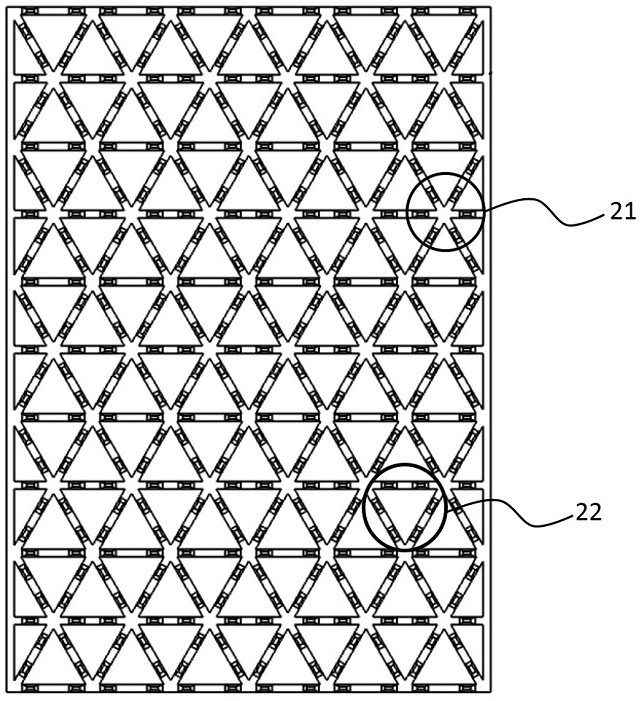

Embodiment 1

[0021] The application is an anti-slip step for machine tools, including a step body 1 and a step tread 3; the step body includes left and right sides 10, a kick surface 15 perpendicular to the tread, a back surface 13 and a bottom surface 12; the step tread 3 is arranged on At the top of each step, the step tread 3 is a mesh structure; the mesh of the mesh structure is an equilateral triangle 22, and anti-skid nails are arranged on the mesh structure. Anti-skid studs 2 are arranged on the side strips of the equilateral triangles of the grid, and the anti-skid studs 2 have a quadrangular truss structure with a small top and a large bottom. Each anti-skid stud and its adjacent anti-skid studs form a "V"-shaped groove.

Embodiment 2

[0023] The present application is an anti-slip step for a machine tool, The step tread is a mesh structure; the mesh structure Anti-skid studs 2 are arranged on the side bars of the equilateral triangle 22 of the grid, and the anti-skid studs 2 are in a quadrangular truss structure with a small top and a large bottom.

[0024] The present application relates to an anti-skid step for machine tools. The step tread surface 3 is composed of several equilateral triangles 22 parallel to each other. Anti-skid studs are distributed on the side strips of equilateral triangle 22, wherein the anti-skid studs 2 have a square-edge structure, and each anti-skid stud 2 and the anti-skid studs 2 on the adjacent side strips are distributed in a "V" shape, theoretically a "V" shape The included angle is 60°. When the anti-skid studs 2 are stepped on to generate pressure, two adjacent anti-skid studs will form a "V"-shaped component force, so that the resultant force is focused on the apex of t...

Embodiment 3

[0026] The step body 1 of the present application is a semi-enclosed aluminum alloy shell composed of left and right sides 10, a back side 13, a bottom surface 12, a built-in slope 14, and a kick surface 15 perpendicular to the tread surface. The built-in slope 14 of the step body 1 is connected to each The surface forms a triangular structure, on the one hand, it makes the steps stronger, and on the other hand, it is convenient for the coolant and cutting materials falling into the steps to reach the cleaning tank near the bottom boundary along the inclined surface 14, which is convenient for cleaning and can keep the step tread and platform An opening is provided near the cleaning tank 16 on the left side 10, which is convenient for cleaning out cooling liquid and other waste materials.

[0027] There are two steps in this embodiment, and more steps can be set as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com