Computer shell burr grinding device

A computer and shell technology, which is applied in the field of computer shell burr grinding devices, can solve the problems of inability to closely contact the computer shell, different smoothness, and inability to automatically bear the force of the computer shell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

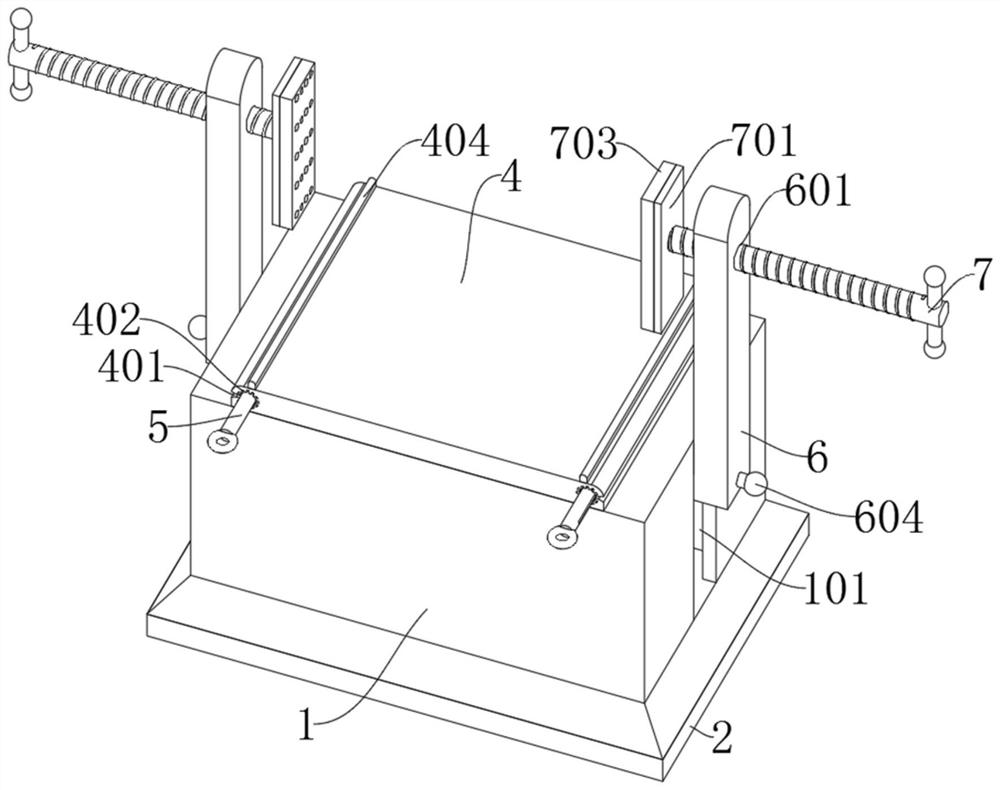

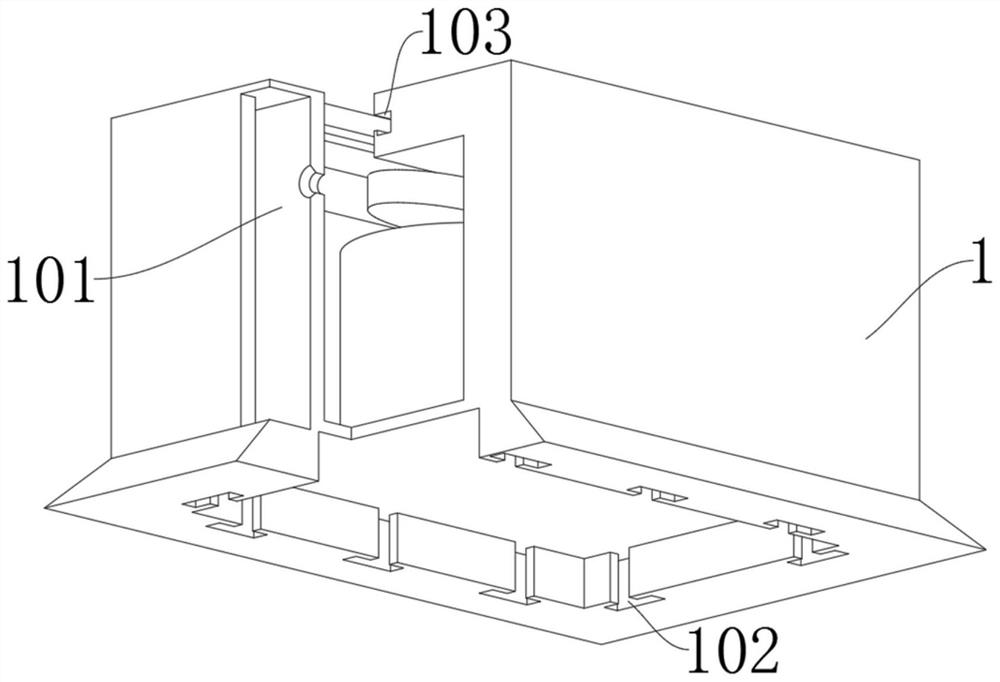

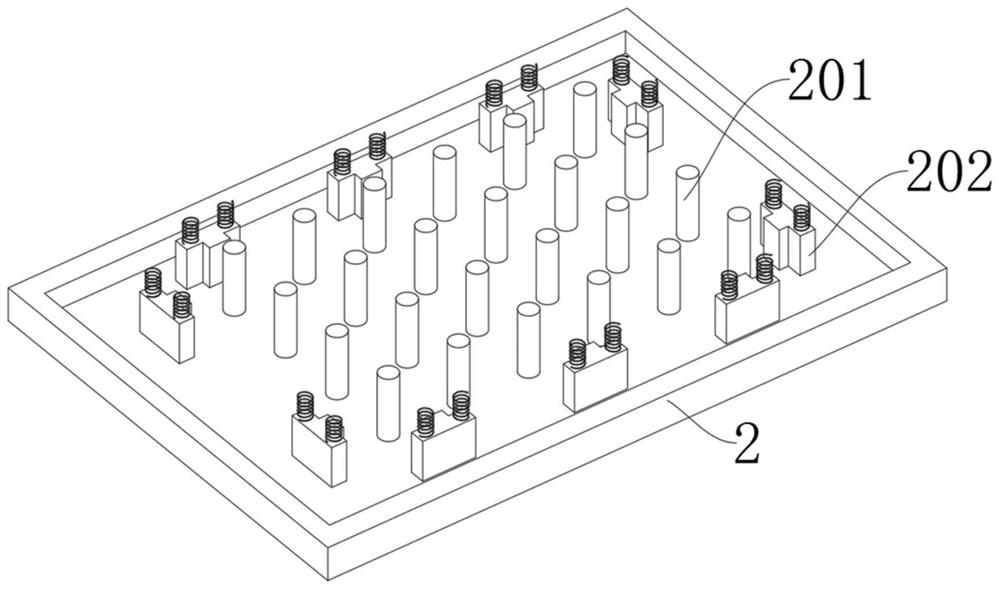

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The present invention provides a computer housing burr grinding device, comprising: a main body 1, a bottom part 2, a guide part 3, a moving plate 4, a rotating part 5, a moving rod 6 and an adjusting rod 7; the main body 1 is a rectangular structure, and the main body 1 The inner bottom end of the motor is embedded with a motor, and the top of the motor is equipped with a cam through the transmission rod; the bottom part 2 is connected to the bottom of the main body 1 through a fixed connection, and the guide block 202 inside the bottom part 2 is embedded and installed in the bottom groove 102, and the top of the guide block 202 is connected to the inside of the bottom groove 102 through a spring; the guide 3 is embedded in the inside of the top groove 103, and the side of the guide 3 is connected to the inside of the top groove 103 through a spring , and the inside of the rectangular groove at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com