Automatic fixed-length rope cutter

An automatic length-fixing and rope cutter technology, which is applied in the field of rope cutters, can solve the problems of low cutting efficiency and achieve the effects of high cutting efficiency, improving segment efficiency and changing cutting length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

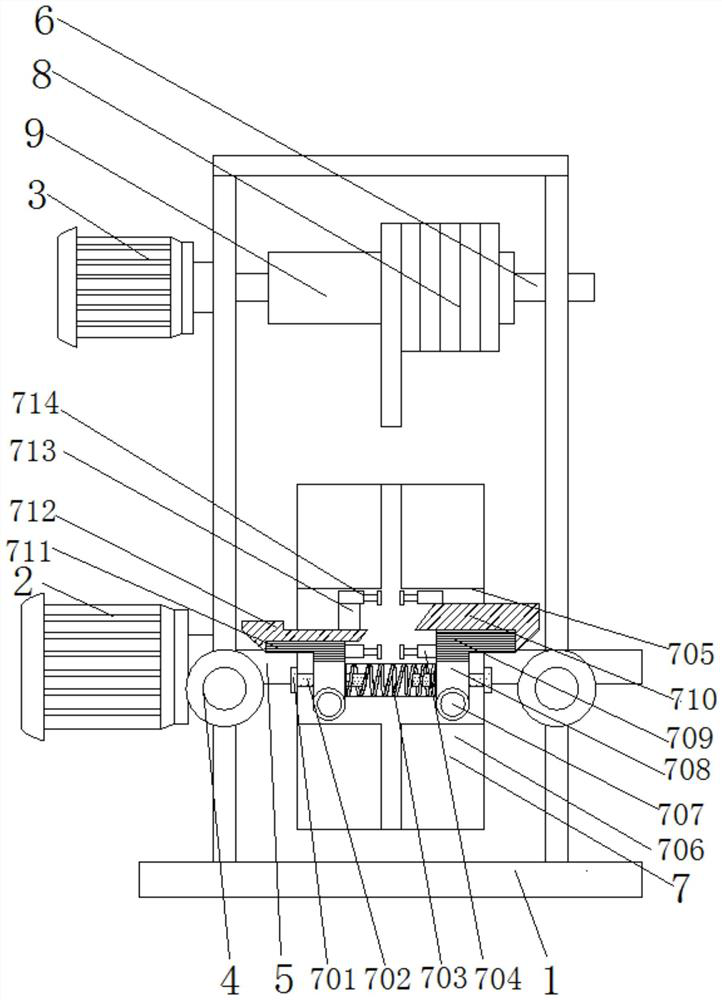

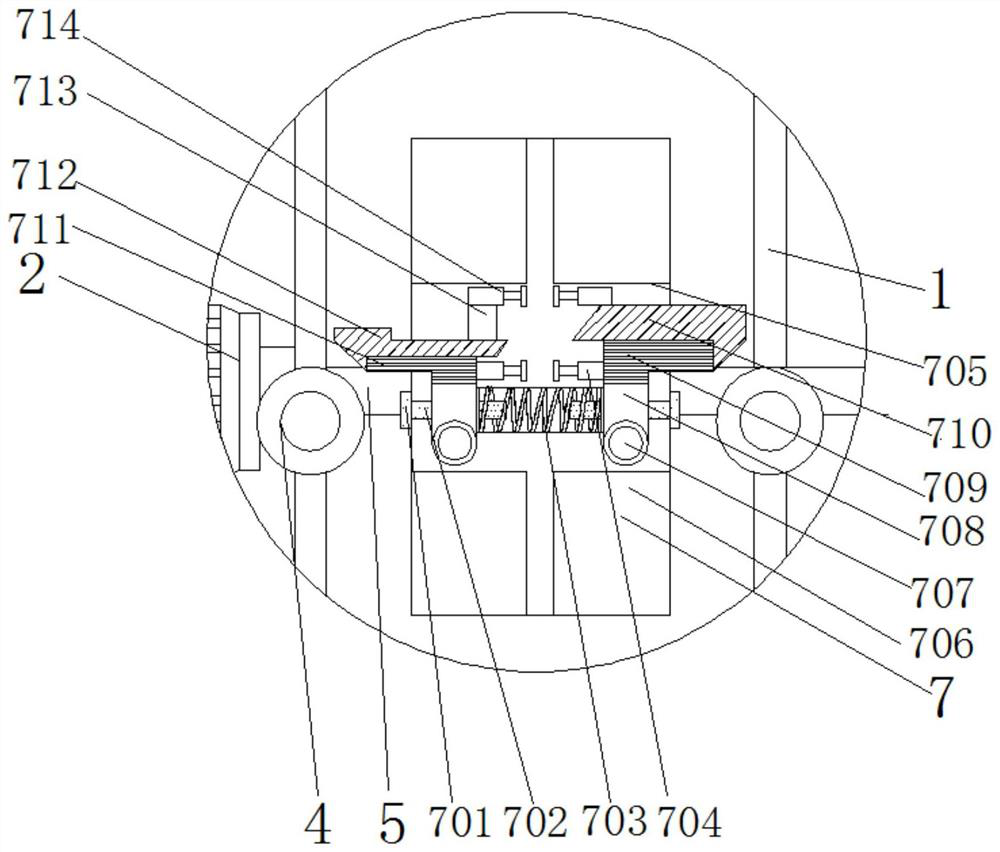

[0028] see Figure 1-4 , an automatic fixed-length rope cutter, including a frame 1 and a cutting mechanism 7, the cutting mechanism 7 includes a fixed block 701, a pin 702, a compression spring 703, a first telescopic rod 704, an arc groove 705, a cutting wheel 706, Screw 707, connecting block 708, first seven-character plate 709, first blade 710, second seven-character plate 711, second blade 712, spacer 713 and second telescopic rod 714;

[0029] The inside of the frame 1 is provided with a cutting wheel 706, the central part of the cutting wheel 706 is fixedly connected with a first major axis 5, and the left and right ends of the first major axis 5 are connected to the left and right ends of the lower end of the frame 1. On the side, the left end of the first long axis 5 is fixedly connected with the first motor 2 , and the first motor 2 is fixed on the left side wall of the frame 1 .

[0030] The frame 1 is used to carry the entire mechanism, and the frame 1 is symmetri...

Embodiment 2

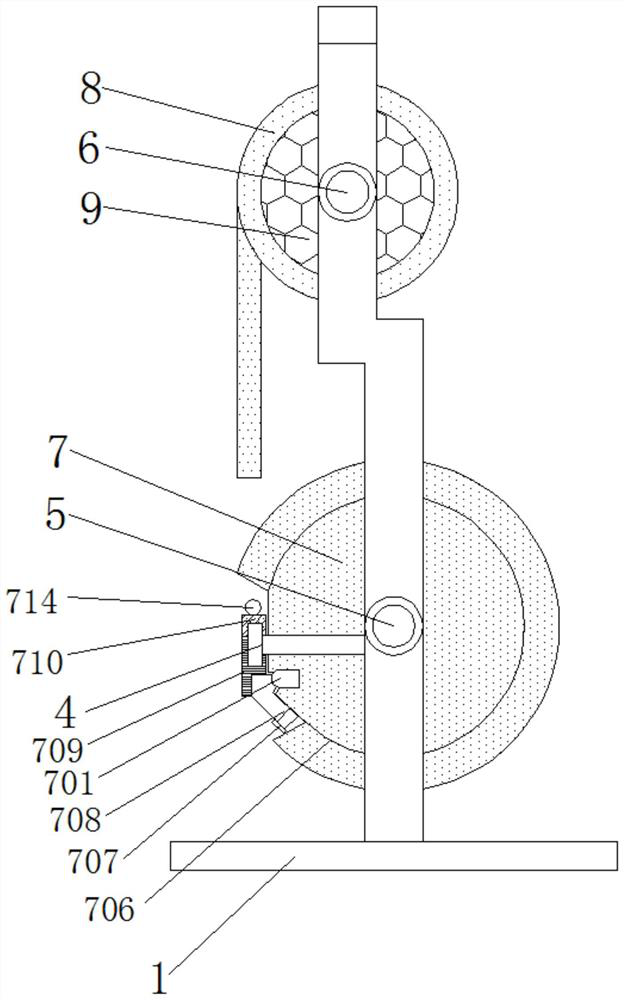

[0042] see figure 1 and 3 , an automatic fixed-length rope cutting device, the upper end of the frame 1 is provided with a second long axis 6, and the left and right ends of the second long axis 6 are connected to the left and right sides of the frame 1;

[0043] A second motor 3 is fixedly connected to the left end of the second long axis 6, and the second motor 3 is fixed to the left side wall of the frame 1;

[0044] The middle part of the second long axis 6 is fixedly sleeved with a roller 9 , and the outer wall of the roller 9 is wound with a loop 8 .

[0045] The middle part of the second major axis 6 is fixedly sleeved with a roller 9, and the outer wall of the roller 9 is wound with a rope loop 8, and the rope is free to fall by rotating the second major axis 6; on the other hand, the second major axis 6 is connected to the second The rotation of the motor 3 is controlled by the motor 3, which makes the structure more simplified.

[0046] The solution in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com