A kind of dust removal device based on green building construction site concrete mixer

A technology for a concrete mixer and a construction site, which is applied to clay preparation devices, mixing operation control devices, and raw material supply devices for sale, etc., can solve problems such as low practicability, aggravate dust, pollute the environment, etc., and achieve improved practicability and adaptability , the effect of improving stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

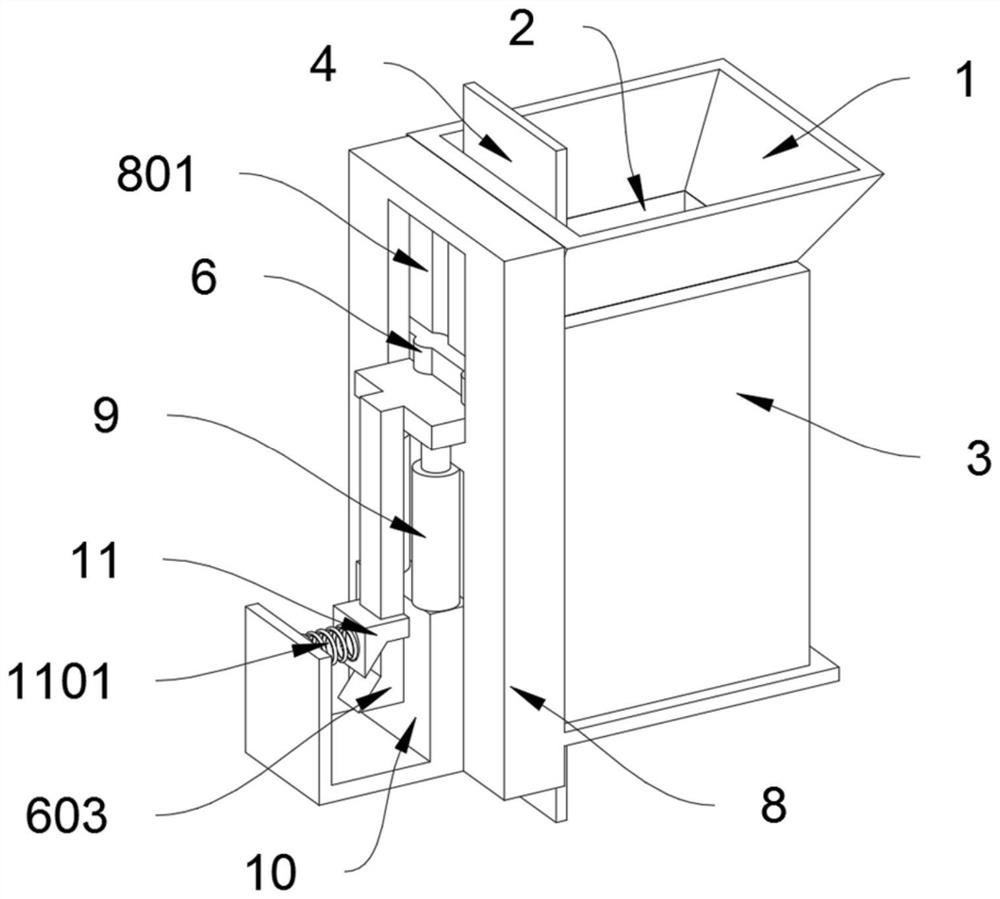

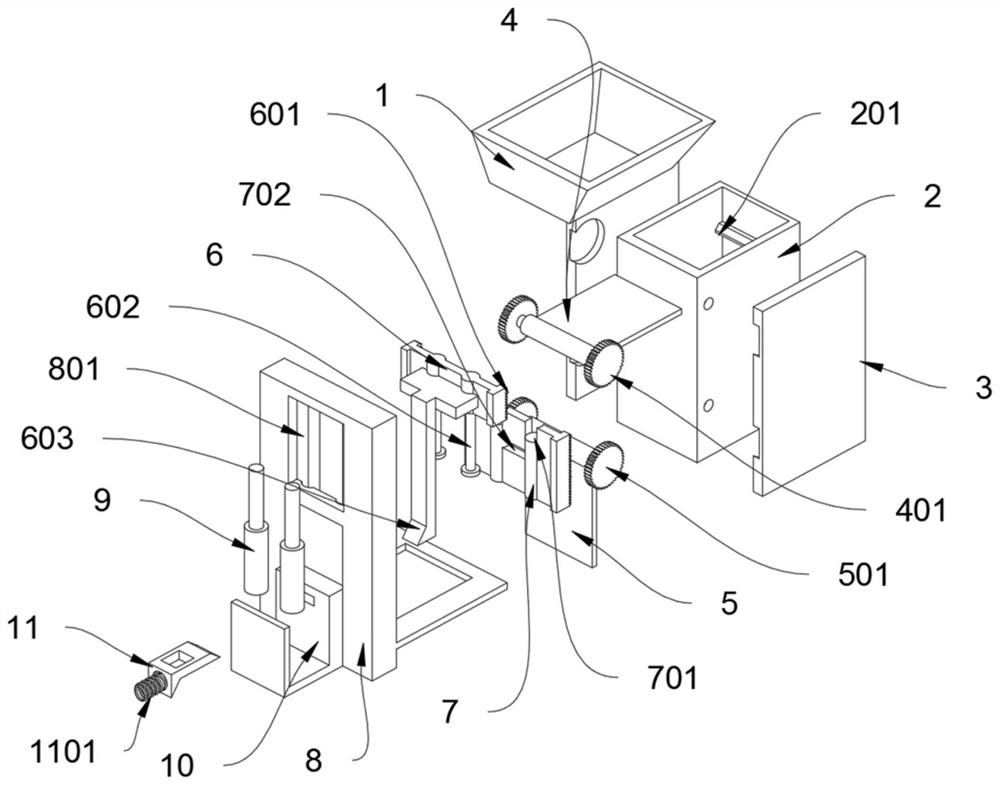

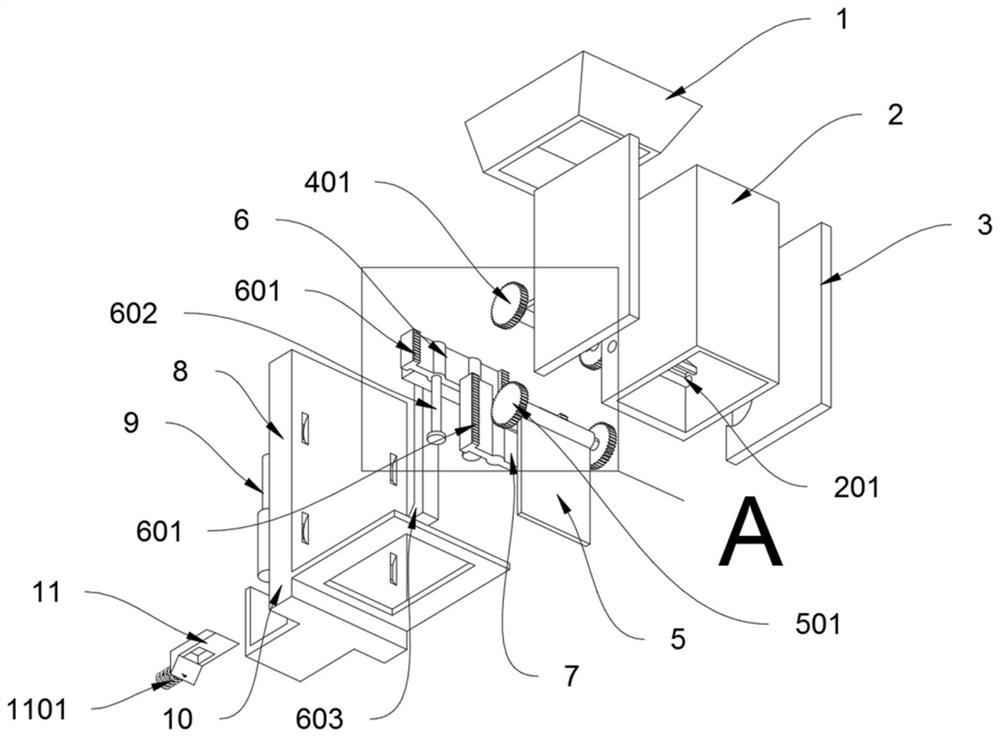

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a dust removal device for a concrete mixer based on a green building construction site, which includes a feeding funnel 1, a side plate 3, a top dustproof plate 4, a bottom compartment plate 5, a dustproof drive block 6, and a compartment drive block 7 , electric push rod 9 and locking hook 11; feed funnel 1 is screwed and fixed on the top of feed channel 2; installation side plate 3 is screwed and fixed on both sides of feed channel 2; top dustproof plate 4 is rotatably connected to the top of the feed channel 2; the bottom compartment plate 5 is rotatably connected to the bottom of the feed channel 2; the dust-proof drive block 6 is plugged into the top of the drive housing 8; the compartment drive block 7 is plugged into the The bottom of drive shell 8; The both sides of top dust-proof plate 4 are provided with dust-proof gear 401, and the both sides of bottom compartment plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com