Integrated crushing system for backfill soil

A crushing system and integrated technology, applied in the field of earthwork crushing, can solve the problems of easy occurrence of dust, threatening the health of construction workers, and scattered debris, and achieve the effect of avoiding dust splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

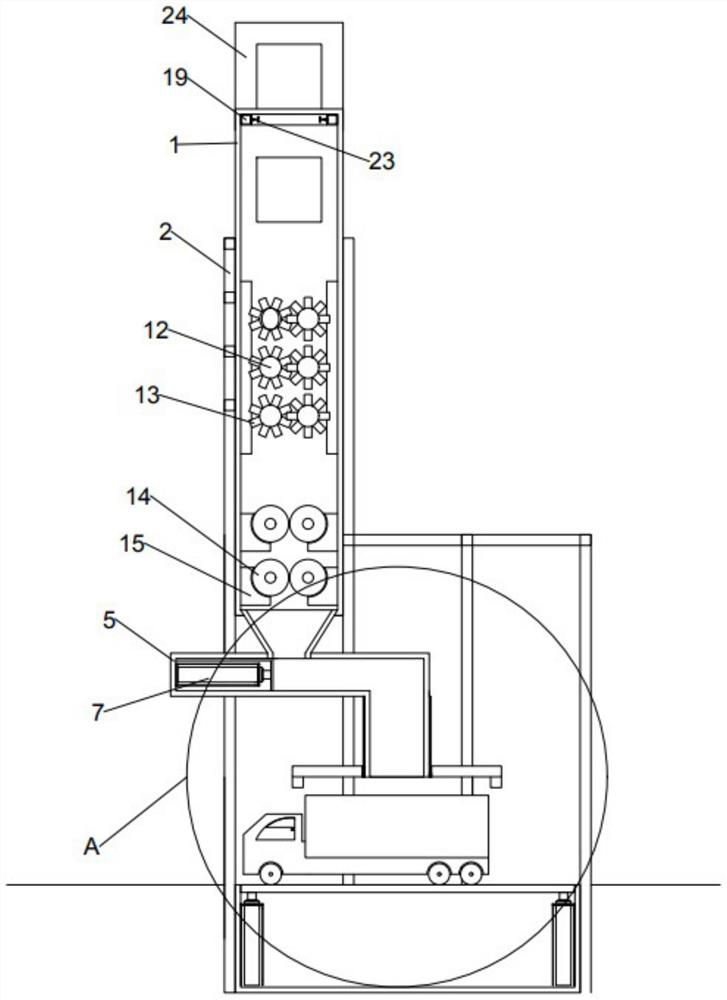

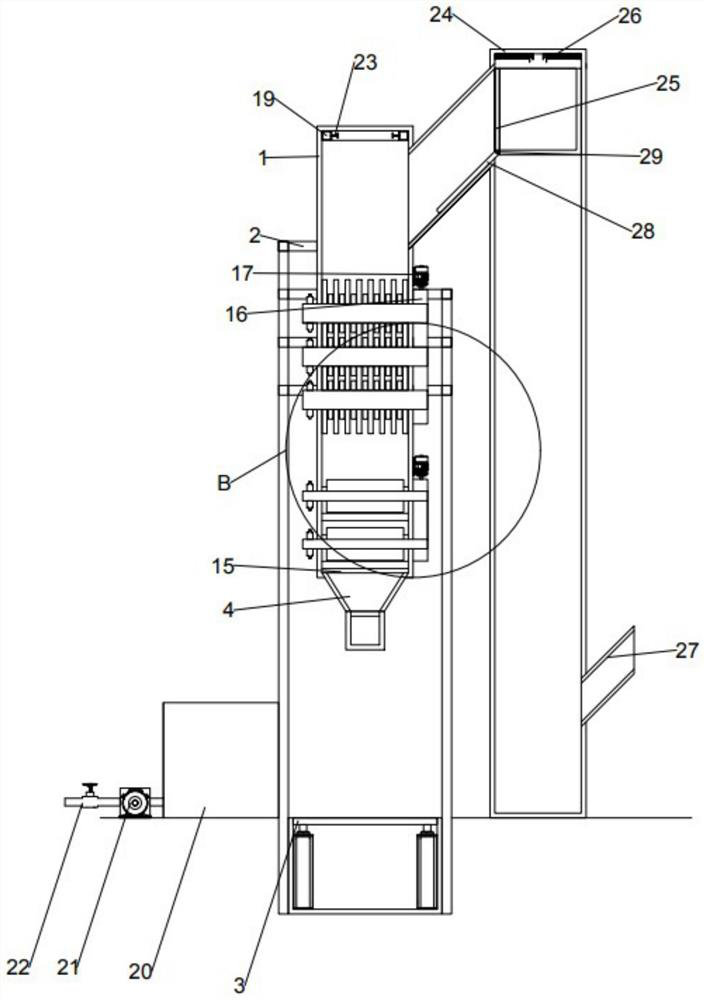

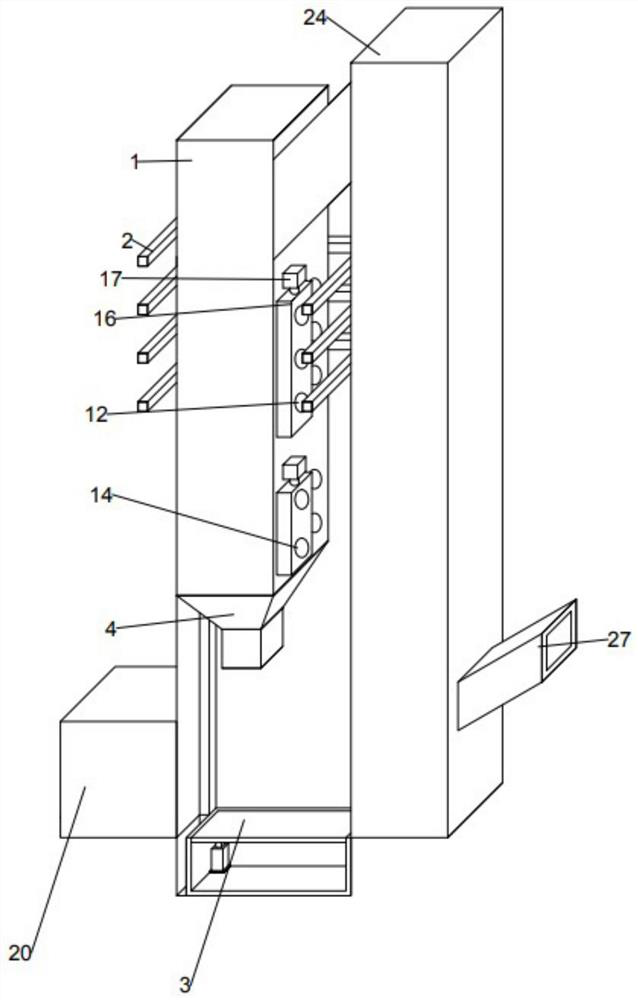

[0028] like Figure 1-5As shown, an integrated crushing system for backfilling soil material includes: crushing container 1, processing support 2 and collecting lifting plate 3, the crushing container 1 is installed on the processing support 2, and the inner side of the crushing container 1 A sealing and feeding structure, a crushing structure and a dust removal structure are installed, a drainage structure is installed on the processing support 2, the drainage structure is connected to the crushing container 1, and the collecting lifting plate 3 is installed on the On the processing bracket 2; the drainage structure includes: a horn-shaped drainage tube 4, an L-shaped drainage tube 5, an L-shaped discharge push plate 6, a discharge drainage hydraulic push rod 7, four pairs of lifting and discharging slideways 8, four For the lifting and unloading slider 9, the loop-shaped shielding plate 10, the loop-shaped shielding sealing block 11 and the lifting adjustment assembly; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com