Safety valve gripping device

A technology for grabbing devices and safety valves, which is applied in the field of grabbing devices for safety valves, can solve problems such as unreliable grabbing methods for safety valves, and achieve the effects of avoiding falling of safety valves, no impact on accuracy, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

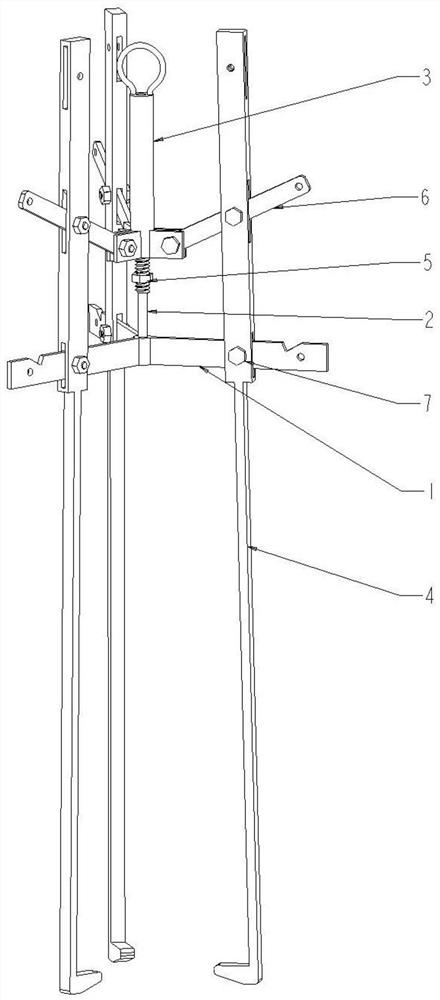

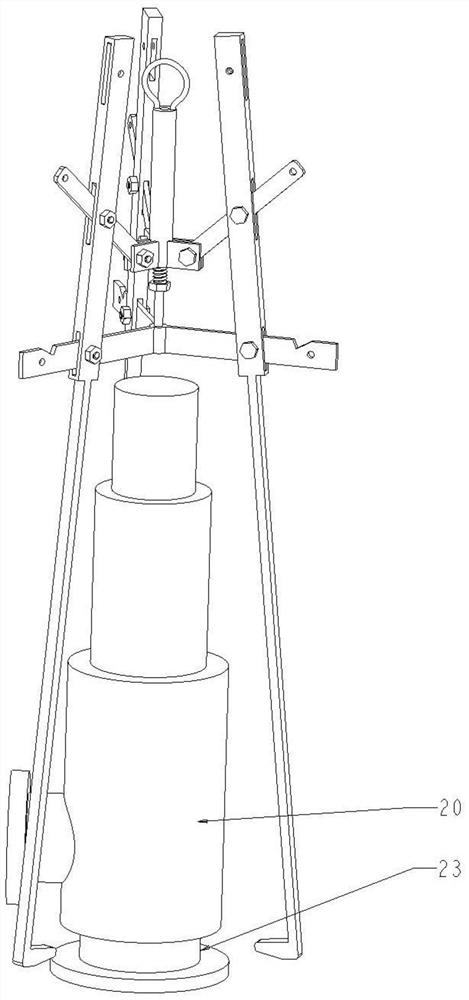

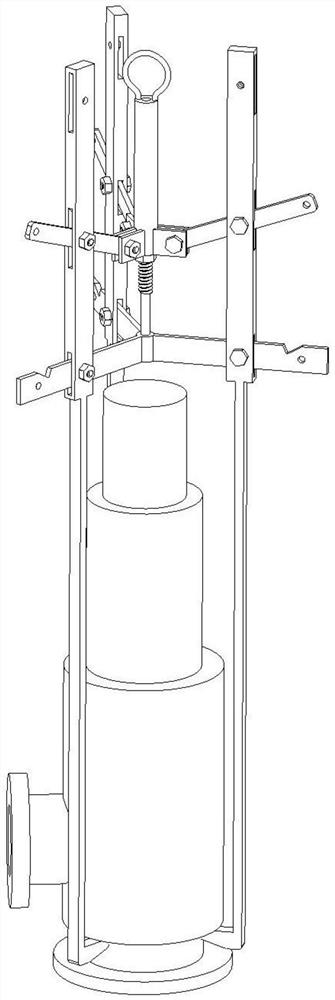

[0039] refer to Figure 1-Figure 10. A grabbing device for a safety valve of the present invention comprises a support rod 1, a guide rod 2, a lifting rod 3, an arm 4, a connecting rod 5, a lock nut 6, and a bolt and nut assembly 7; Rod 1 and guide rod 2 are welded on one end side wall, and the support rod 1 and the guide rod 2 form a central support; the support rod 1 is provided with an adjustment hole; The nut assembly 7 is connected, and the bolt and nut assembly passes through the adjustment hole on the pole 1 and the bolt hole on the arm 4, and the pole 1 can rotate around the bolt; one end of the connecting rod 6 and the arm 4 pass through the bolt and nut respectively. The assembly 7 is connected, the bolt and nut assembly passes through the screw hole on the connecting rod 6 and the bolt hole on the arm 4, and the connecting rod 6 can rotate around the bolt; the other end of the guide rod 2 is the optical axis, and the middle side The wall is processed with external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com