Hollow whipstock capable of conducting tie-back

A skewer and hollow guiding technology, which is applied in drilling equipment, drilling equipment and methods, earthwork drilling and production, etc., can solve the problems of inability to guide branch wellbore strings and strings into branch wellbore, and achieve favorable The effect of entering the operation, saving operation time and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

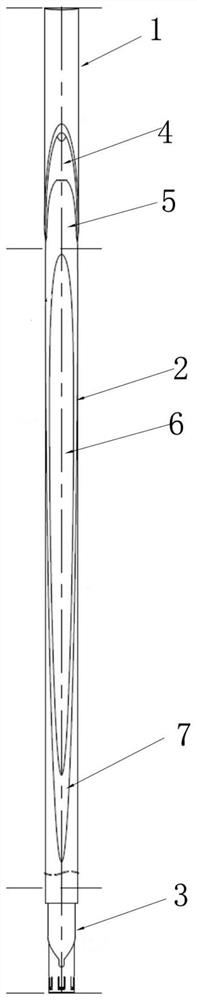

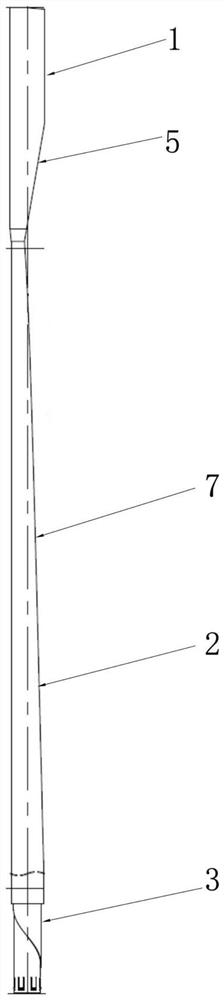

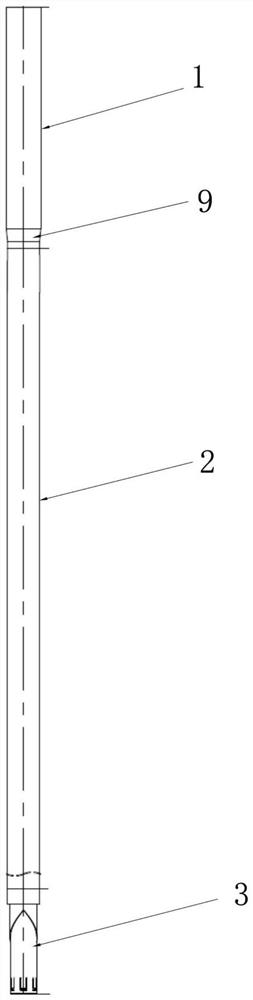

[0027] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0028] like Figures 1 to 3 As shown, the reconnectable hollow oblique device provided by the present invention includes a hollow return part 1, a hollow guide part 2 and a hollow reinsertion part 3 arranged in sequence from top to bottom, the three are arranged concentrically with the central axis, and the hollow guide part 2 is located between the hollow return part 1 and the hollow return part 3, the upper end of the hollow guide part 2 is connected with the lower end of the hollow return part 1, and the lower end of the hollow guide part 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com