Flow guiding and blocking sealing structure for high-pressure turbine disc rear bearing cavity

A high-pressure turbine and sealing structure technology, which is used in the lubrication of turbine/propulsion devices, gas turbine devices, and engine lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

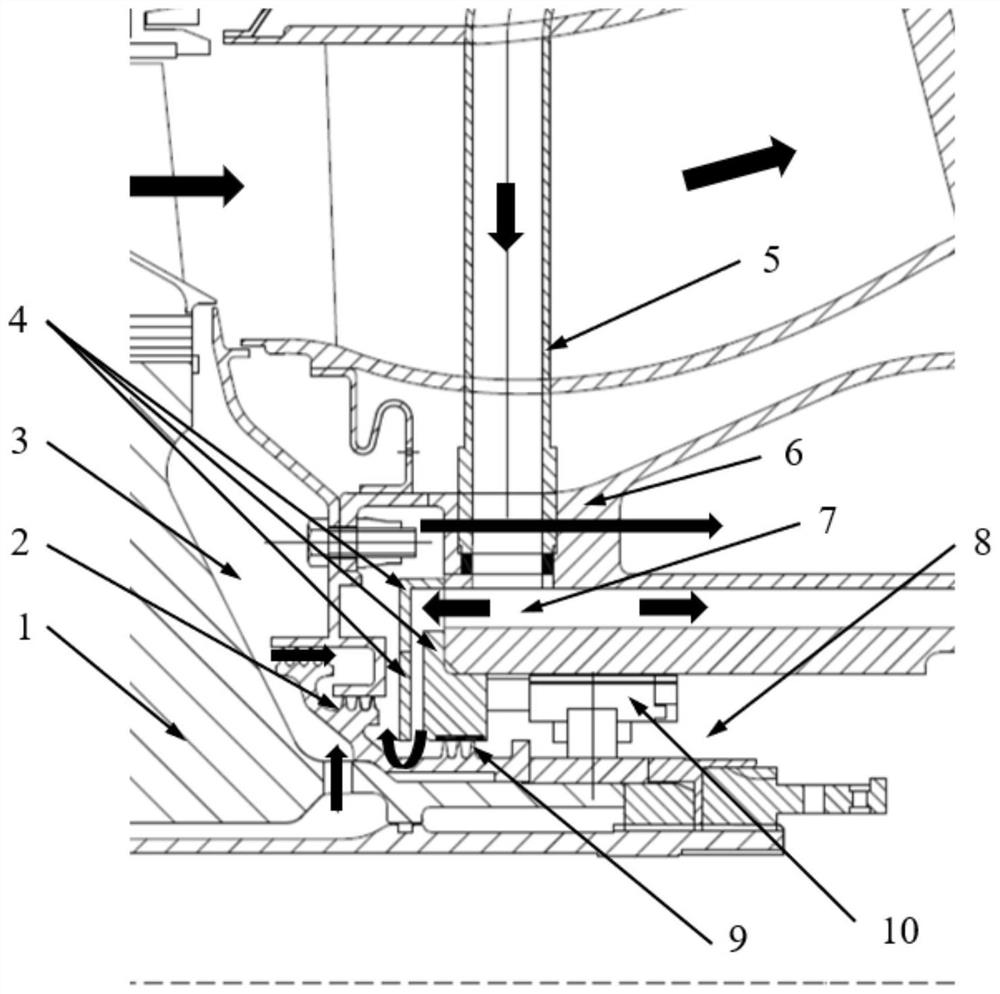

[0020] Such as figure 1 As shown, the flow diversion blocking sealing structure for the bearing cavity behind the high-pressure turbine disk of the present invention includes a high-pressure turbine disk 1, a multi-layer grate rotor sealing ring 2, a sealing seat 4, a load-bearing casing 6, and a low-temperature airflow channel 5. Bearing 10 behind the high-pressure turbine disc. The load-bearing casing 6 is arranged on the downstream side of the high-pressure turbine disk 1, and the radial inner side of the load-bearing casing 6 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com