Control method for preventing ignition deflagration of gas stove and gas stove

A control method and technology for gas stoves, which are applied in the field of gas stoves, can solve the problems of small aperture of an inner ring nozzle, deflagration, deflagration, etc., and achieve the effect of avoiding deflagration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

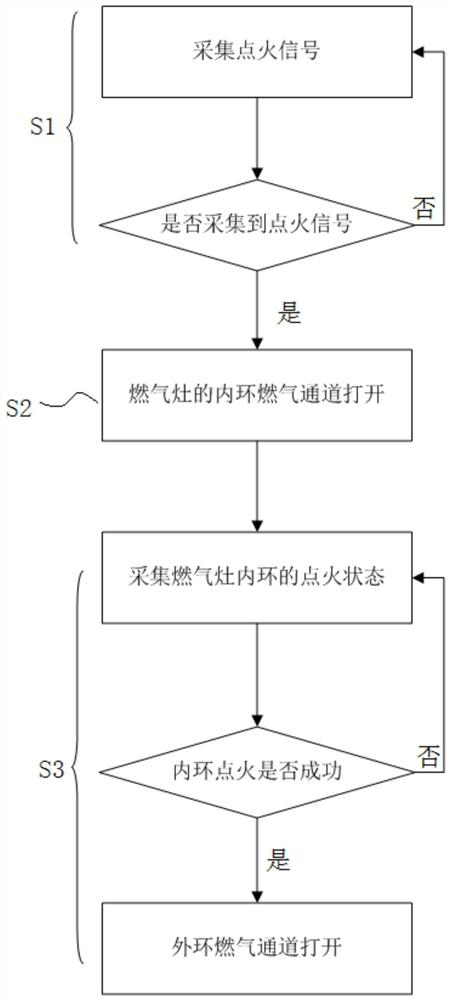

[0035] Embodiment 1 of the present invention provides a control method for preventing ignition and deflagration of gas stoves, such as figure 1 As shown, the specific steps are as follows:

[0036] S1, collect the ignition signal, enter S2 when the ignition signal is collected, otherwise continue to collect;

[0037] Specifically, the controller collects the state of the gas stove cock, and enters S2 when the cock is pressed, otherwise the controller continues to collect the state of the gas stove cock;

[0038] Whether the user presses the valve stem of the plug valve is collected through the controller. If there is a press, it proves that the user is igniting the ignition. At this time, enter S2, otherwise continue to collect;

[0039] S2, the inner ring gas channel of the gas stove is opened;

[0040] It should be noted that the existing ignition method is to ignite the inner ring first, and then transmit the fire to the outer ring through the inner ring. Therefore, the g...

Embodiment 2

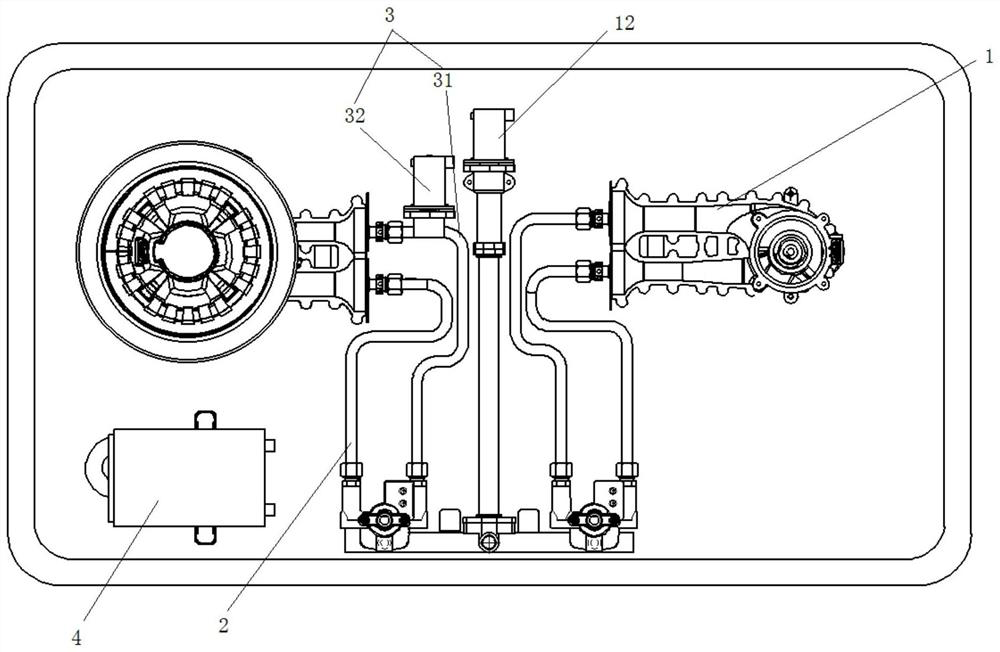

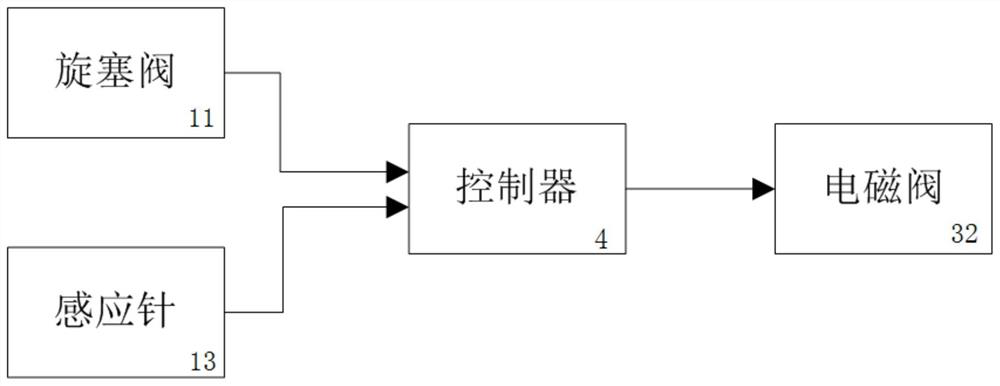

[0049] Embodiment 2 of the present invention provides a gas stove capable of preventing ignition and deflagration, which applies the control method for preventing ignition and deflagration of the gas stove described in Embodiment 1, such as Figure 2-3 As shown, it includes a gas stove body 1, an inner ring gas channel 2, an outer ring gas channel 3 and a controller 4, the inner ring gas channel 2 and the outer ring gas channel 3 both provide gas for the gas stove body 1, and the The input end of the controller 4 is connected to the inner ring of the body 1, and the output end is connected to the outer ring gas channel 3; the controller 4 controls the on-off of the outer ring gas channel 3 according to the ignition state of the inner ring;

[0050] In this way, with the above structure, when the gas stove body 1 needs to be ignited, the controller 4 receives a signal to control the opening of the inner ring gas channel 2, and when the inner ring is successfully ignited, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com