A position measuring device and solenoid valve based on Hall sensor

A Hall sensor and measuring device technology, applied in the mechanical field, can solve problems such as large measurement error, and achieve the effect of simple and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

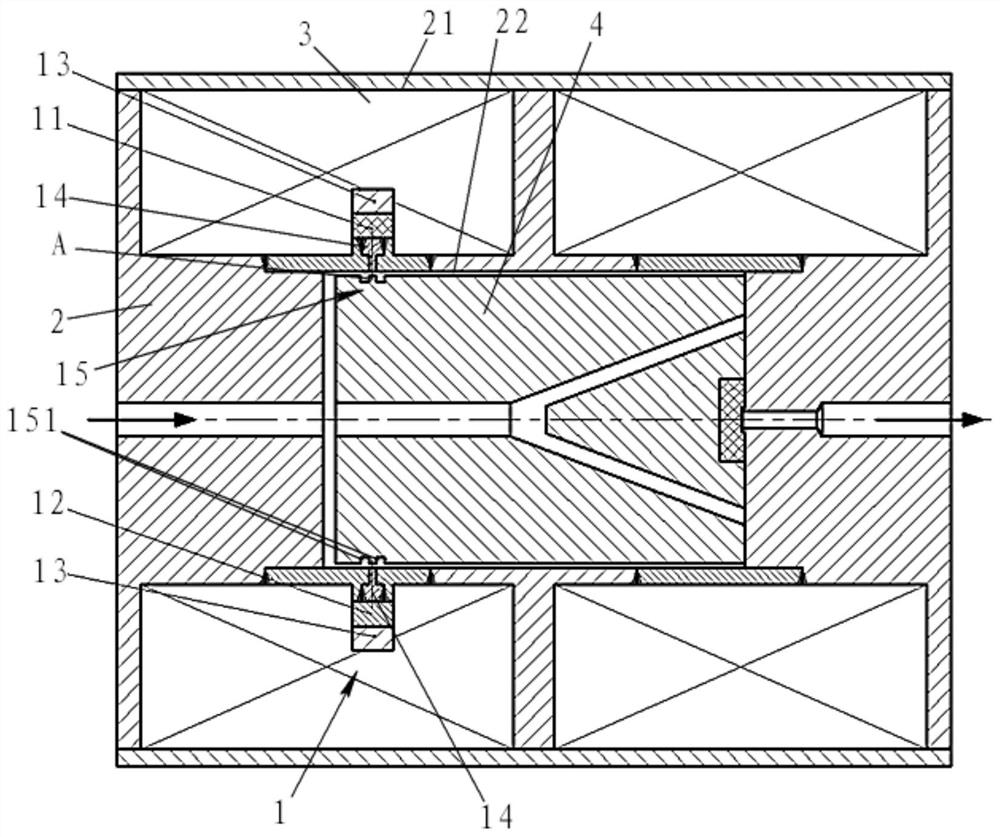

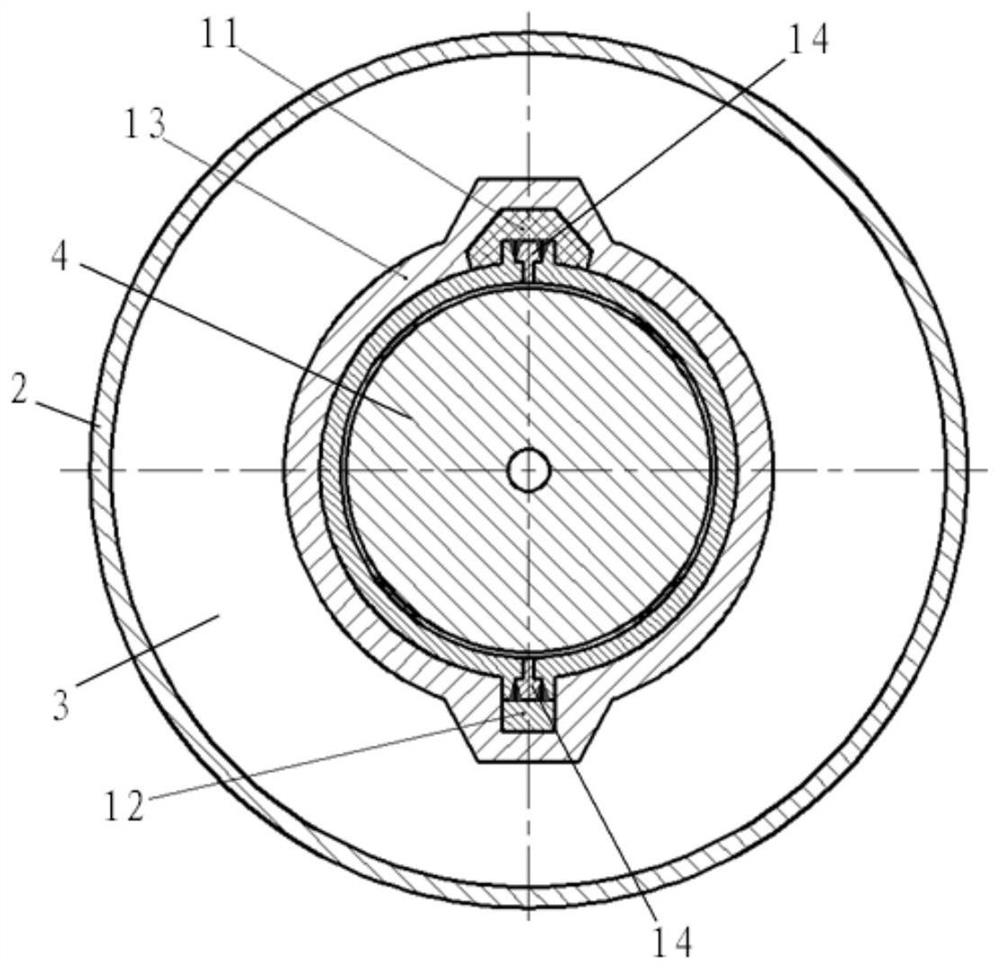

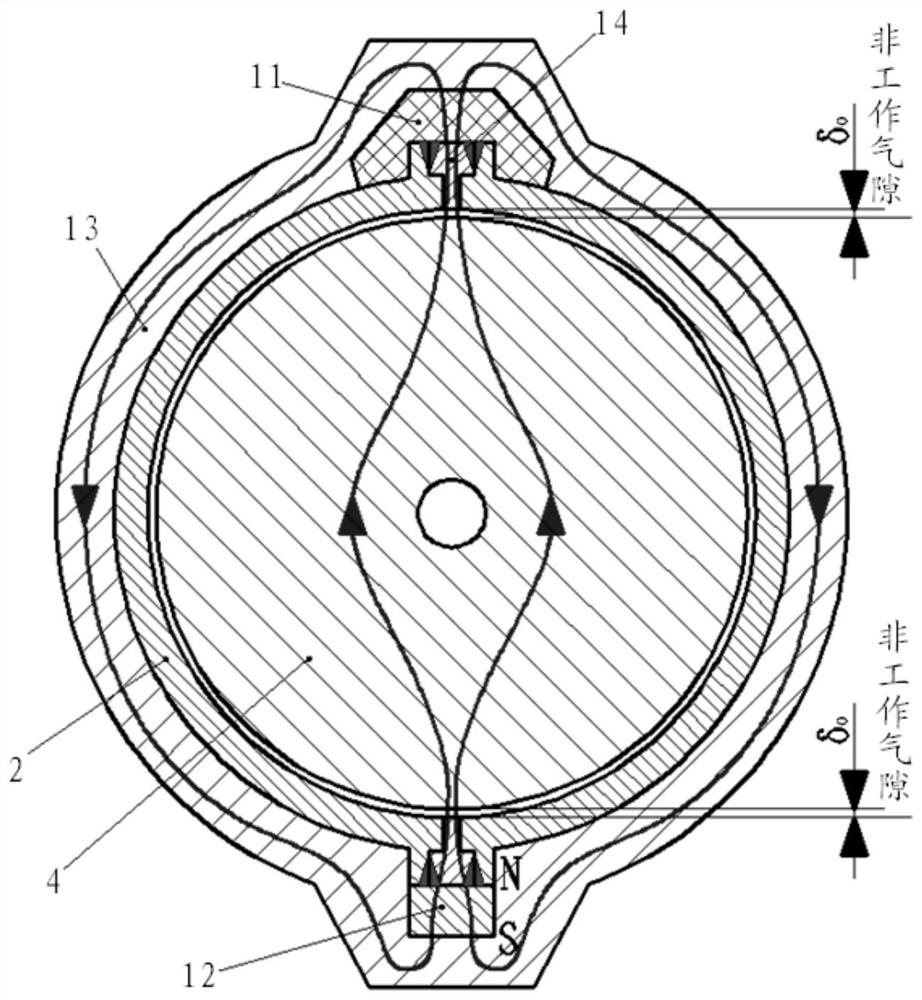

[0034] Combine figure 1 with figure 2 As shown, according to an embodiment of the present invention, a position measuring device of the Hall sensor, comprising: a Hall sensor 11, magnetic steel 12, which is opposed to the Hall sensor 11, is used to connect Hall. The sensor 11 and the magnetic steel 12 are used for magnetic magnetic ring 13, corresponding to the Hall sensor 11 and the magnetic steel 12, and the first magnetic splitting member 14, which is disposed, and two first magnetic splitters located opposite. 14 The second magnetic passage 15 between 14. In the present embodiment, the magnetic ring 13 is integrated, the Hall sensor 11 and the magnetic steel 12 are disposed relative to the inside of the magnetic ring 13, and the Hall sensor 11 and magnet steel 12 are respectively connected to the magnetic ring 13, respectively. Depending on, the polar Sole (or N pole) connected to the magnetic steel 12 and the magnetic tone ring 13 is connected to the Hall sensor 11 and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com