Soil-loosening rake tooth for harvesting water chestnuts

A technology for picking teeth and horseshoes, which is applied to the field of loosening and picking teeth for harvesting horseshoes, can solve problems such as large slippage, reduce the squeeze and wear of horseshoe fruits, increase the contact area, reduce the probability of horseshoe damage, and the scope of use. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

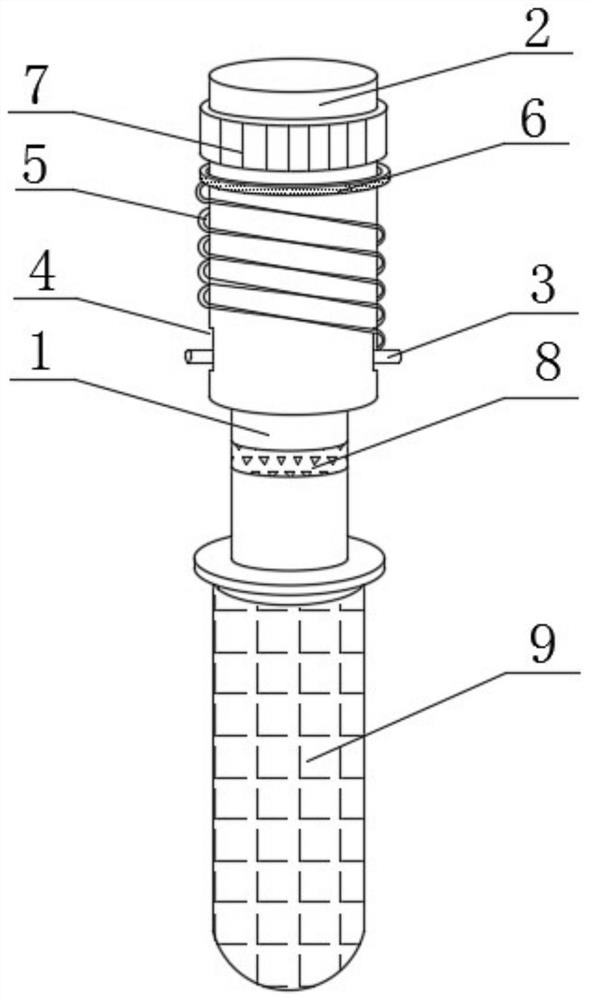

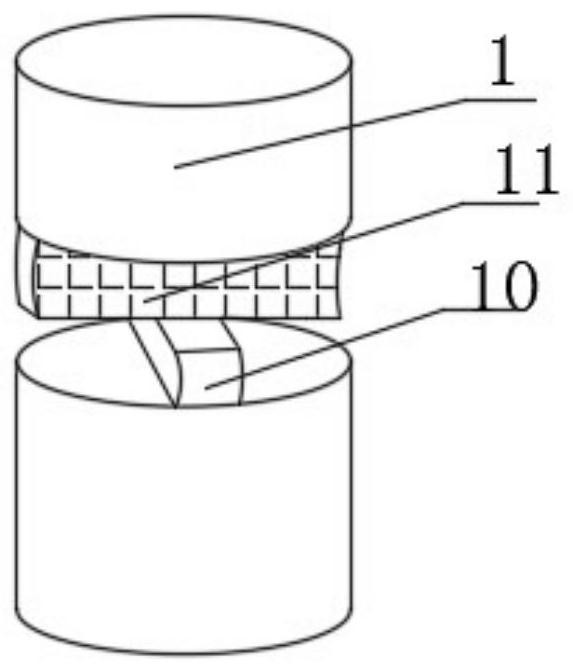

[0024] A loosening tooth for harvesting horseshoes, comprising a rake bar 1, a sleeve 2 is sheathed on the outer side of the upper end of the rake bar 1, and a latch 3 is arranged on the sleeve 2 through the upper end of the rake bar 1, and the two sides of the sleeve 2 are There is a long slot 4 for the movement of the latch 3, a No. 1 spring 5 is sleeved on the outer side of the sleeve 2, and a spring sheath 6 is connected to the upper end of the No. 1 spring 5, and the outer side of the sleeve 2 is close to the upper end of the spring sheath 6 An adjusting nut 7 is movable installed, and a buffer structure 8 is provided at the middle position of the pick bar 1, and a buffer structure 8 is provided at the middle position of the pick bar 1, and the buffer structure 8 includes No. 1 spring steel 10 and No. 2 spring steel 11. The lower end surface of the No. 1 spring steel 10 is fixed to the lower section of the grill bar 1, the upper end face of the No. 2 spring steel 11 is fix...

Embodiment 2

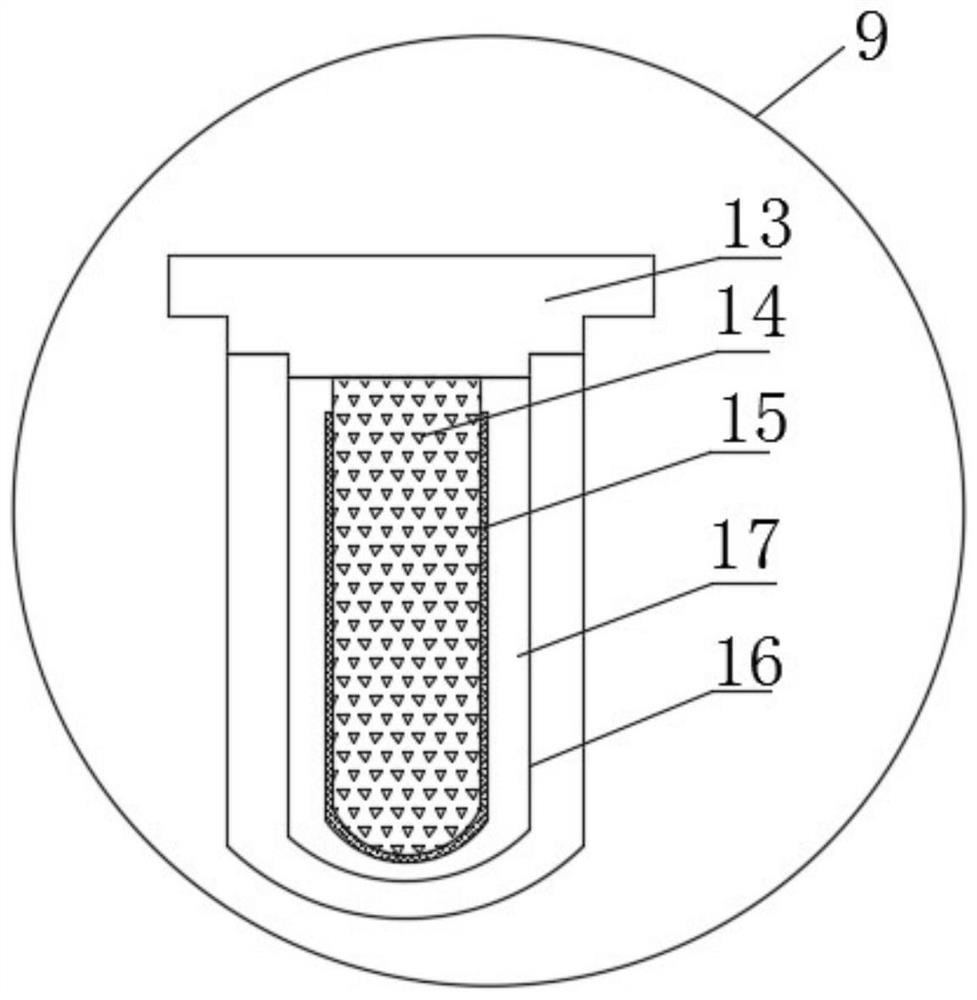

[0028] On the basis of Embodiment 1, the grilling tooth structure 9 is the first structure, and the grilling tooth structure 9 includes a cylindrical step 13 and a cylindrical rod 14, and the cylindrical rod 14 is fixedly arranged at the lower end of the cylindrical step 13, and the cylindrical rod The outer side of 14 is closely attached to inner layer rubber sleeve 15, and the outer side of inner layer rubber sleeve 15 is provided with 2-5 groups of outer layer rubber sleeves 16, adjacent outer layer rubber sleeve 16 and inner layer rubber sleeve 15 outer layer rubber sleeve 16 An oil storage cavity 17 is arranged between them, and the oil storage cavity 17 is filled with lubricating oil, and the outer rubber sleeve 16 is bound to the cylindrical step 13 by a locking ring;

[0029] The outer layer rubber cover 16 cooperates with the inner layer rubber cover 15 to play a cushioning effect, which reduces the extrusion damage to the water chestnut fruit, and injects a little lub...

Embodiment 3

[0031] On the basis of Embodiment 1 and Embodiment 2, the racking tooth structure 9 is a second structure, and the racking tooth structure 9 includes a cylindrical step 13 and a cylindrical rod 14, and the cylindrical rod 14 is fixedly arranged at the lower end of the cylindrical step 13 , the outer side of the cylindrical rod 14 is closely attached to the inner layer rubber sleeve 15, and the outer side of the inner layer rubber sleeve 15 is provided with a group of inflatable rubber sleeves 18, and an inflatable cavity 19 is provided between the inflatable rubber sleeve 18 and the inner layer rubber sleeve 15, and the inflatable An air nozzle 20 is installed on one side of the rubber sleeve 18, and the inflatable rubber sleeve 18 is bound to the cylindrical step 13 with a locking ring, and the outer circumference of the cylindrical step 13 is glued to the upper end of the locking ring. lock up;

[0032] The inflatable rubber cover 18 cooperates with the inner layer rubber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com