Composite no-clean dust removal device

A dust removal device and no-cleaning technology, applied in transportation and packaging, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of complex structure of dust removal system, short maintenance period, and complex structure of analysis dust removal system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

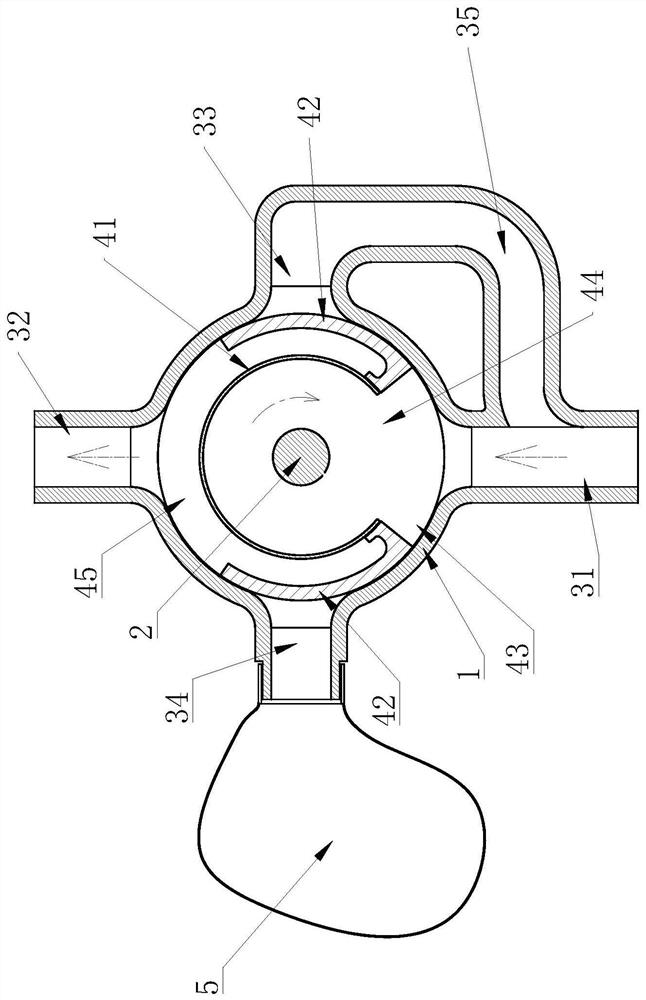

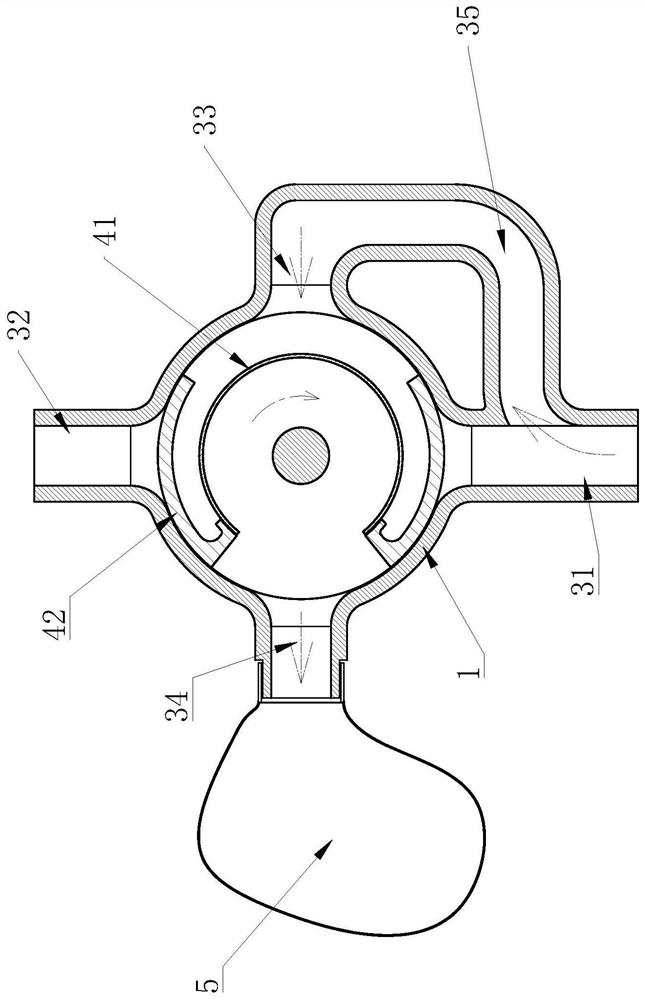

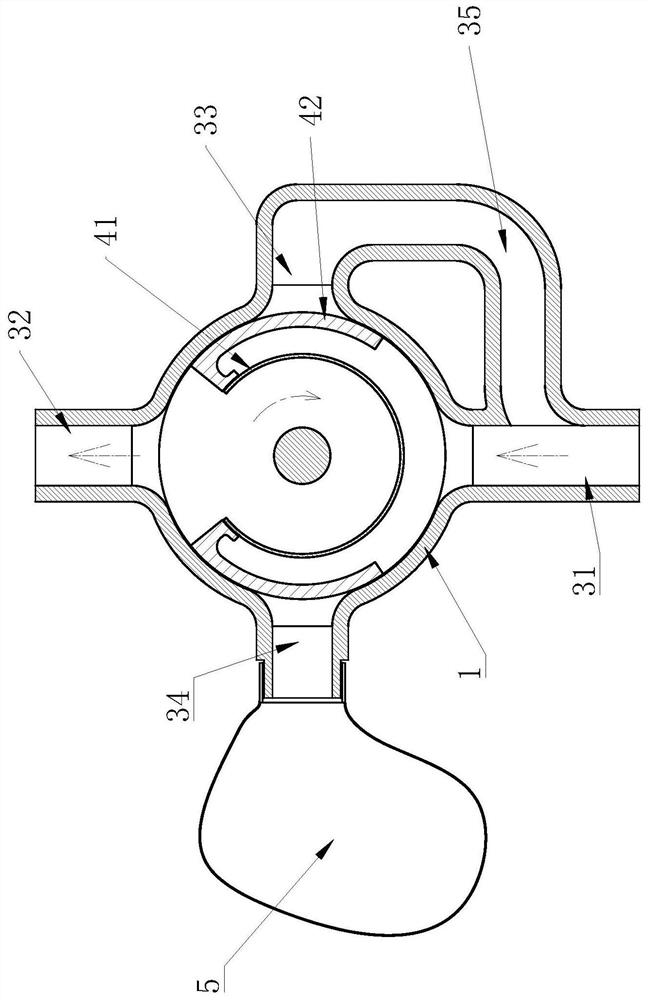

[0027] Such as figure 1 and Figure 5 As shown, it includes a tubular dust removal casing 1 and a rotating shaft 2 that is rotatably connected to the dust removal casing 1. The side wall of the dust removal casing 1 is connected with a main air intake pipe 31, a main exhaust pipe 32, an auxiliary air intake pipe 33 and an auxiliary exhaust pipe. 34. The main intake pipe 31, the main exhaust pipe 32, the auxiliary air intake pipe 33 and the auxiliary exhaust pipe 34 are evenly arranged on the outer side of the dust removal shell 1, and the main air intake pipe 31 and the main exhaust pipe 32 are on the same straight line. The auxiliary air intake pipe 33 communicates with the middle part of the main air intake pipe 31 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com