Mold process with local high-frequency normalization participating in forming

A mold and high-frequency technology, which is applied in the field of online high-frequency normalizing forming process, can solve the problems of prolonged tube-making cycle, high cost, and inability to realize partial normalizing process, etc., and achieve the effect of reducing procurement costs and saving tube-making cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

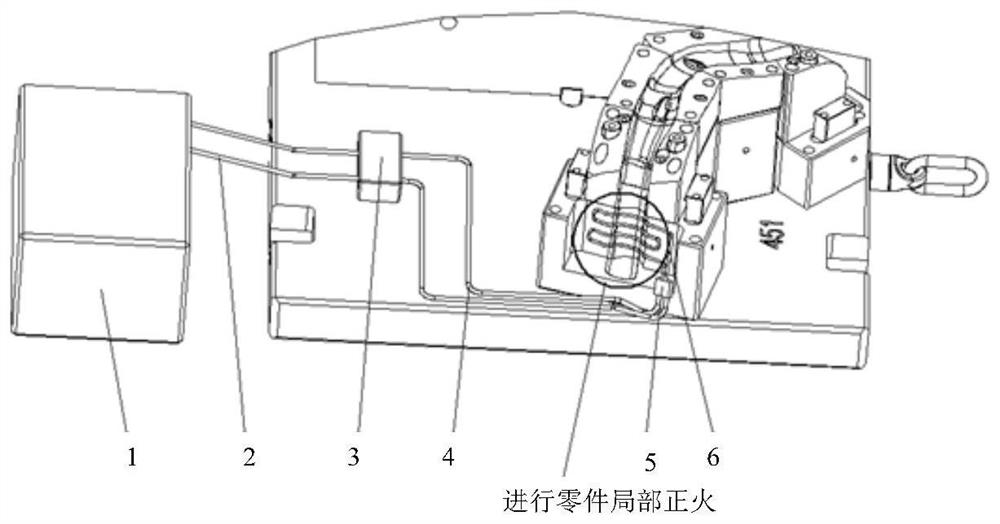

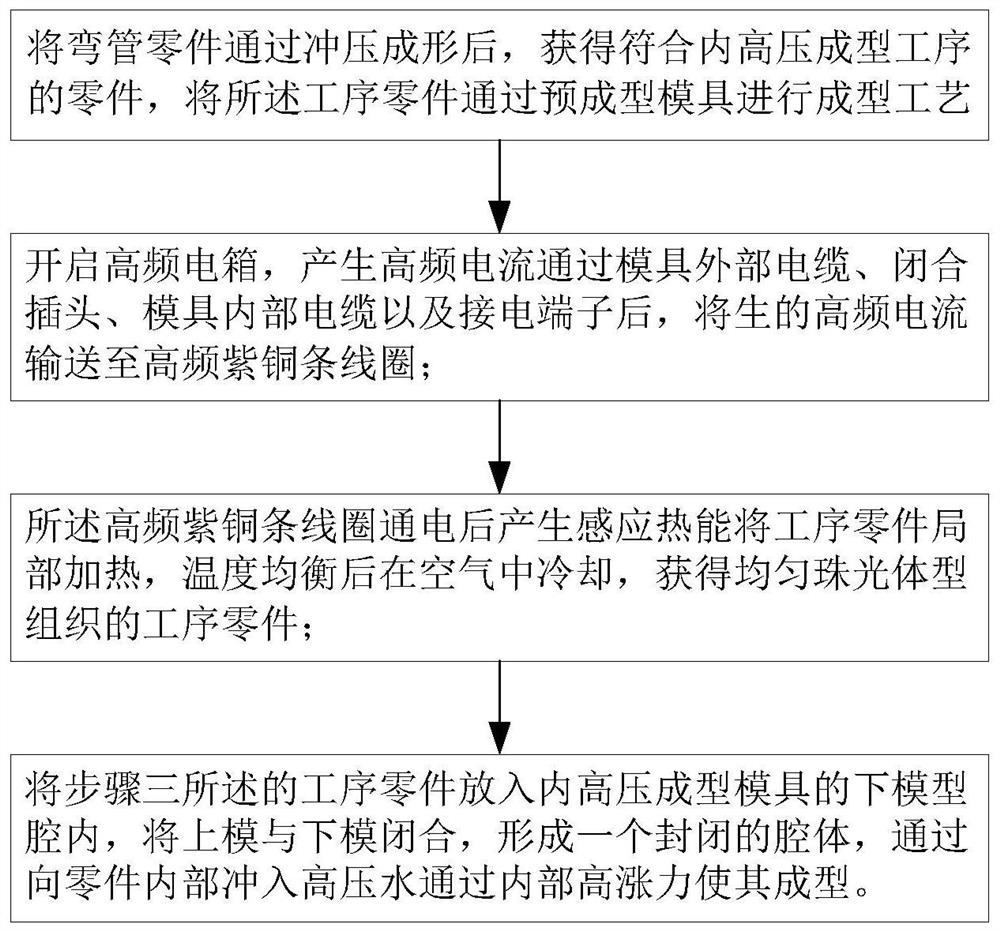

[0015] combine figure 1 and figure 2 Description of this embodiment, a mold process in which local high-frequency normalizing participates in forming, the bent pipe part is pressed into a shape conforming to the internal high-pressure forming process through stamping, and at the same time, the copper strip set in the pre-forming mold is passed through high-frequency The electric current makes it heat up quickly and air cool to achieve the effect of normalizing process.

[0016] The preforming mold includes a mold body, a high-frequency electric box 1, a mold external cable 2, a closing plug 3, a mold internal cable 4, an electrical terminal 5 and a high-frequency copper strip coil 6;

[0017] The closing plug 3 is respectively connected to the mold external cable 2 and the mold internal cable 4, the mold external cable 2 is connected to the high-frequency electric box 1, the mold internal cable 4 is connected to the electric terminal 5, and the terminal 5 It is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com