A mold process with local high-frequency normalizing involved in forming

A mold and high-frequency technology, which is applied in the field of online high-frequency normalizing forming process, can solve the problems of prolonged tube-making cycle, high cost, and inability to realize partial normalizing process, etc., and achieve the effect of reducing procurement costs and saving tube-making cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

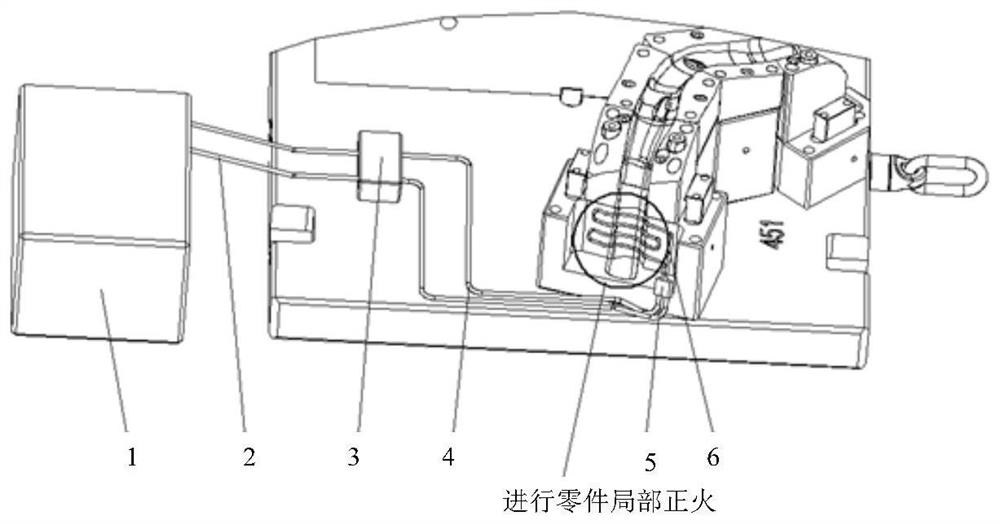

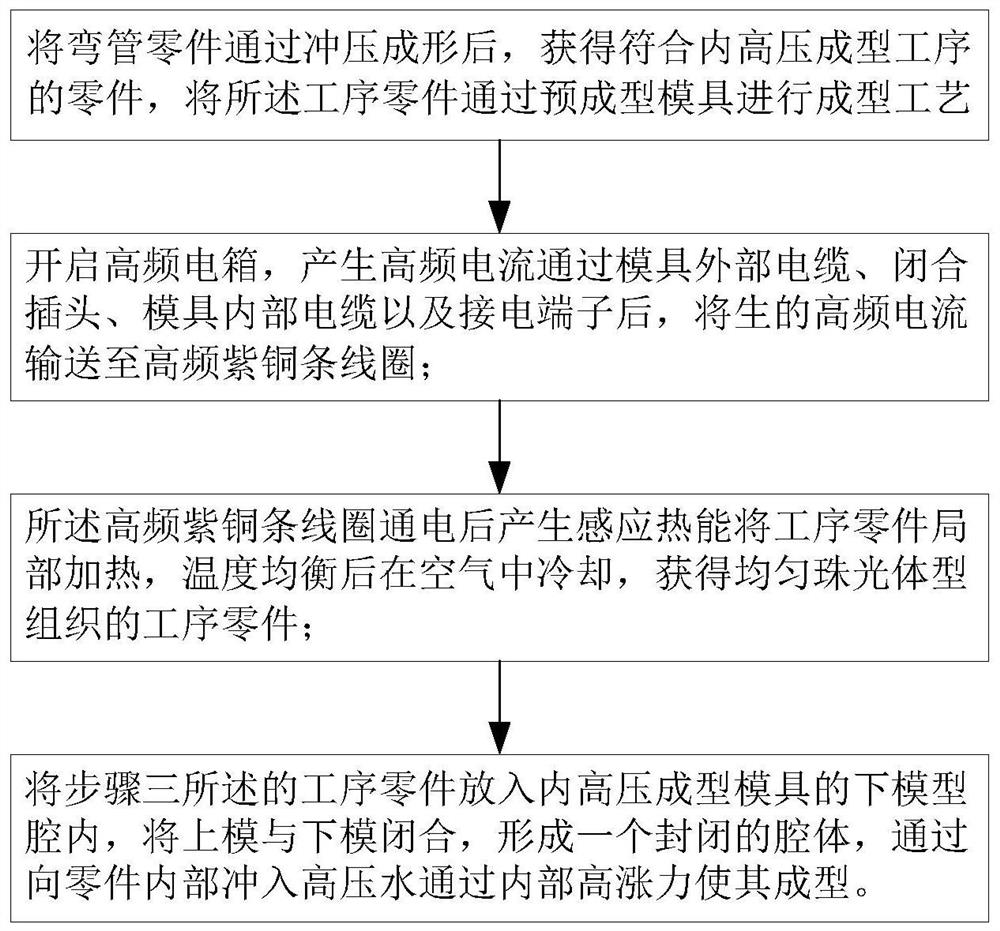

[0015] combine figure 1 and figure 2 Explain this embodiment, a mold process in which local high-frequency normalizing participates in molding, the elbow parts are pressed into parts conforming to the internal high-pressure forming process by stamping and forming, and at the same time, the copper bars set in the pre-forming mold are instantly connected to high-frequency Electric current, make it rapidly heated and air cooled to achieve the effect of normalizing process.

[0016] The pre-forming mold includes a mold body, a high-frequency electric box 1, an external cable 2 of the mold, a closing plug 3, an internal cable 4, an electrical connection terminal 5, and a high-frequency copper strip coil 6;

[0017] The closed plug 3 is respectively connected with the mold external cable 2 and the mold internal cable 4, the mold external cable 2 is connected with the high-frequency electric box 1, the mold internal cable 4 is connected with the power connection terminal 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com