Wall space grinding device for building construction

A technology for building construction and grinding, which is applied in the direction of grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, grinding machines, etc. and other problems, to achieve the effect of improving the effect of dust removal, improving the effect of sealing, and good effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

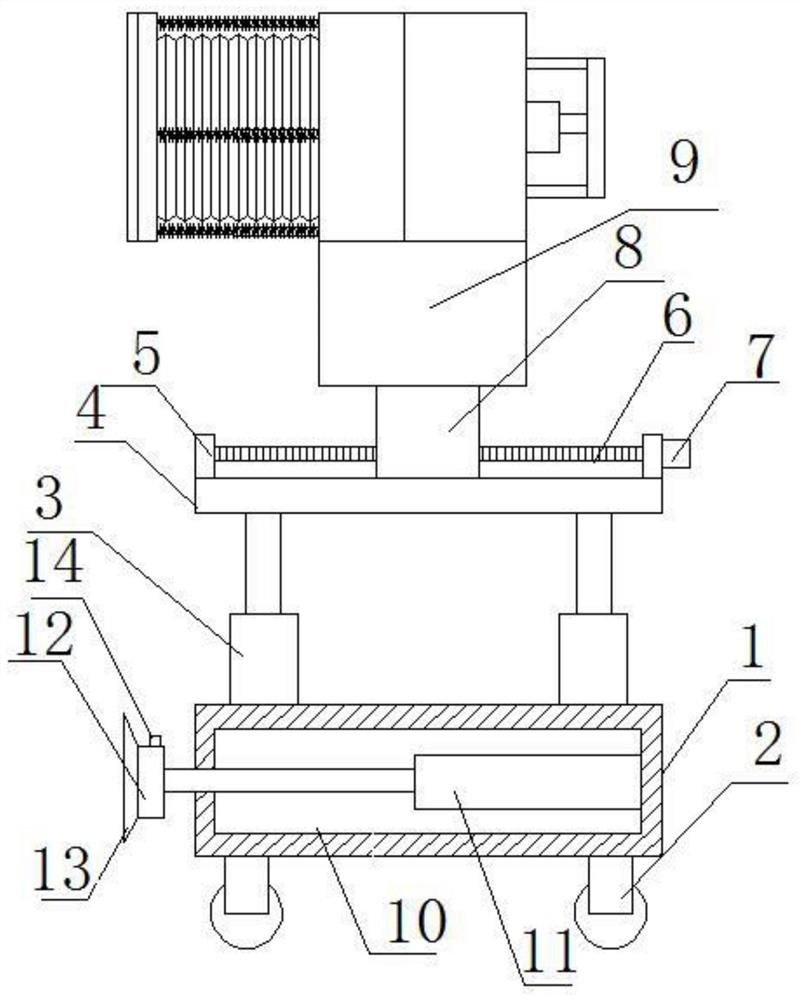

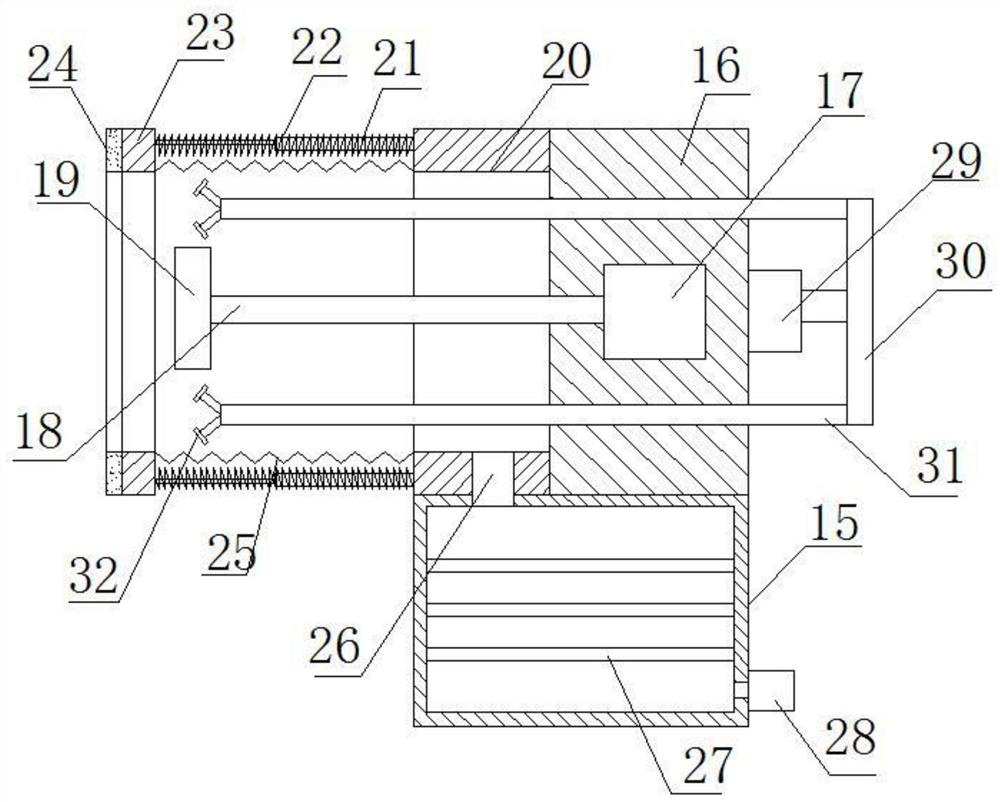

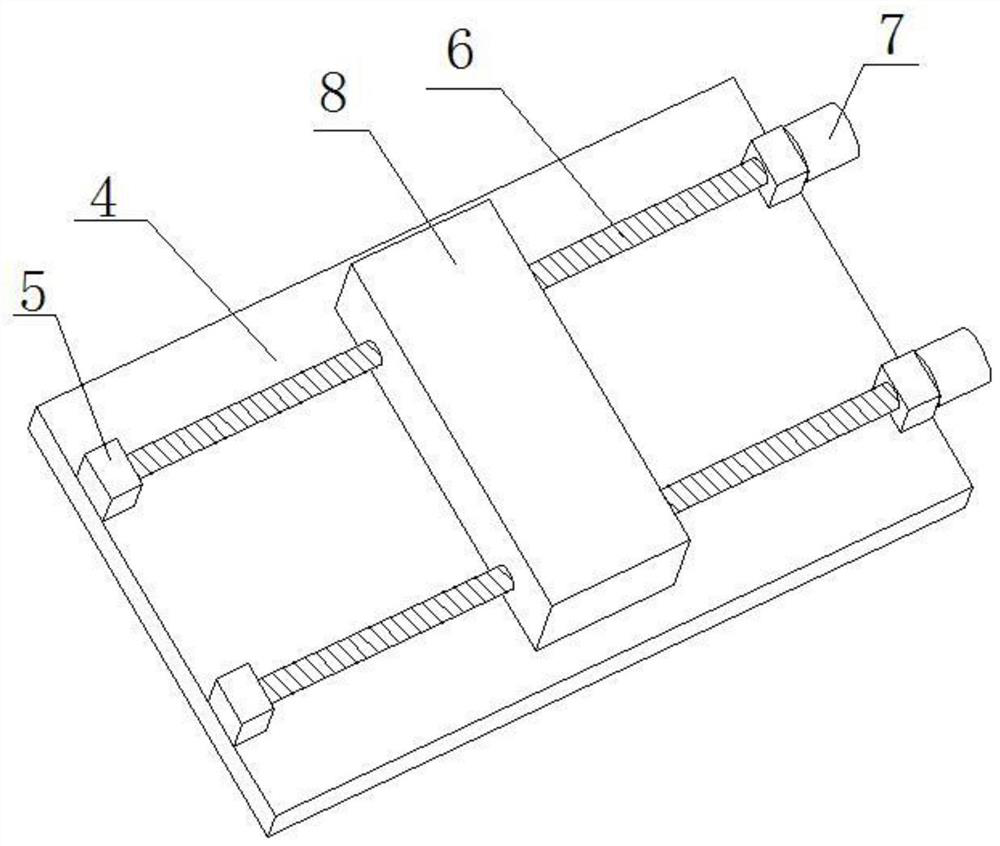

Embodiment 1

[0021] Please refer to 1-3. In the embodiment of the present invention, a wall smoothing device for building construction includes a base 1. The four corners of the lower side of the base 1 are provided with universal wheels 2. The upper side of the base 1 is provided with several The first telescopic mechanism 3, the upper end of the first telescopic mechanism 3 is provided with a left and right moving mechanism, and a grinding mechanism 9 is installed on the left and right moving mechanism, and the grinding mechanism 9 includes a dust collection box 15, and the dust suction The upper end of the box 15 is provided with an organic body 16, the inside of the body 16 is provided with a grinding motor 17, the output end of the grinding motor 17 is provided with a drive shaft 18, and the left end of the drive shaft 18 is provided with a grinding disc 19, The left side of the body 16 is provided with an annular cover 20, and the outer circumference of the left end of the annular cov...

Embodiment 2

[0024] On the basis of the first embodiment, the inside of the base 1 is provided with a cavity 10, and the inside of the cavity 10 is provided with a second telescopic mechanism 11, and the left end of the second telescopic mechanism 11 extends out of the cavity 10 and Connected with a vacuum adsorption mechanism, the vacuum adsorption mechanism includes a vacuum box 12, the left end of the vacuum box 12 is provided with a suction cup 13 communicating with the vacuum box 12, and the vacuum box 12 is provided with a vacuum pump 14 communicating with the vacuum box 12, so Both the first telescopic mechanism 3 and the second telescopic mechanism 11 are electric telescopic rods. With this structure, when the device is working, the suction cup 13 can be used to adsorb the device on the wall, so as to ensure the stability of the device when it is working.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap