Shot blasting machining method for hard rock cutter ring of shield tunneling machine

A processing method and shot blasting technology, applied in metal processing equipment, spray guns, manufacturing tools, etc., can solve the problems of shortening the life of hard rock cutter rings, deformation of thin blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

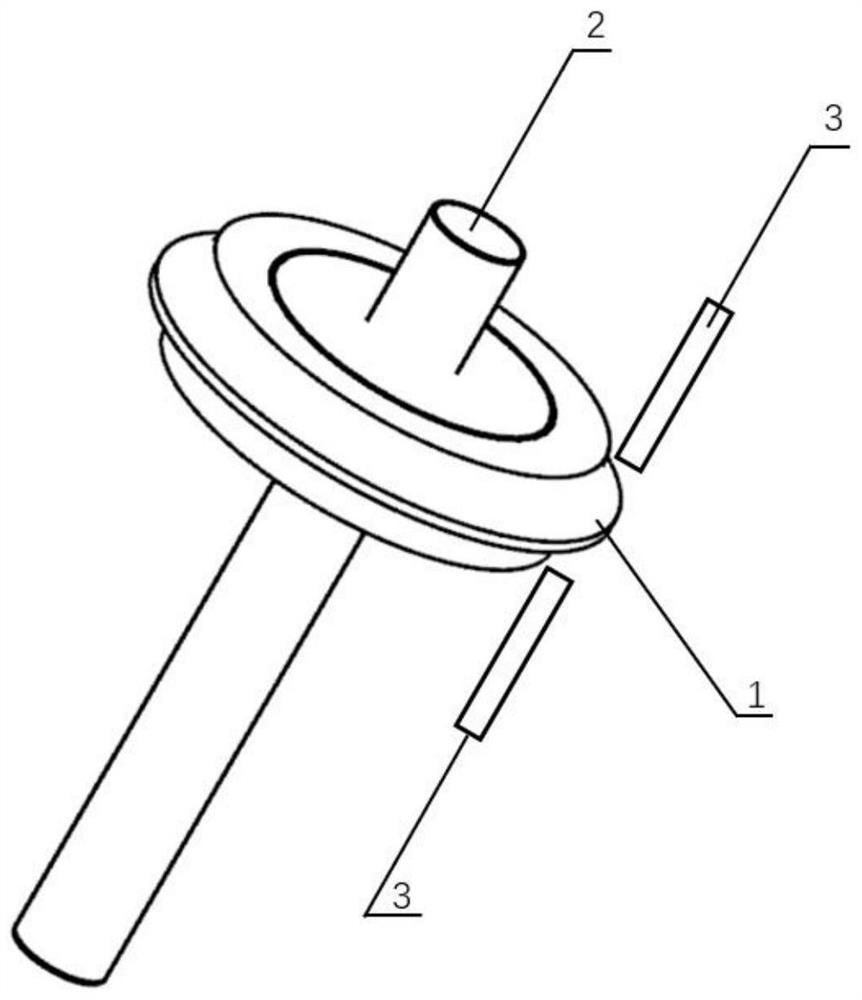

[0036] Fix the hard rock cutter ring on the rotating shaft according to the coincidence of the central axis of the hard rock cutter ring with the central axis of the rotating shaft;

[0037] A 1212P shot blasting machine is used to shot peen the blade of the hard rock knife ring. The shot peening conditions are as follows: the diameter of the knife ring is 17in, and the rotating shaft rotates around the axis at a speed of 10rpm; A 14mm spray gun is used to shot peen the blade area of the hard rock cutter ring of the shield machine (the position extending 28mm from the edge boundary) using the runner injection method, wherein the injection incident angle is 80°, and the shot peening intensity is 0.09A·mm , the shot-peening pressure is 0.4MPa, the shot-peening coverage is 100%, and the spraying time is 7 minutes; the shot-peening shot is cast steel shot with a hardness of 52HRC.

Embodiment 2

[0044] Fix the hard rock cutter ring on the rotating shaft according to the coincidence of the central axis of the hard rock cutter ring with the central axis of the rotating shaft;

[0045] Use 1212P shot blasting machine to blast the blade of hard rock cutter ring. The shot blasting conditions are as follows: the diameter of the cutter ring is 19in, and the rotating shaft rotates around the axis at a speed of 13rpm; A 15mm spray gun is used to shot peen the edge area of the hard rock cutter ring of the shield machine (the position extending 30mm from the edge boundary) using the flow channel injection method, wherein the injection incident angle is 90°, and the shot peening intensity is 0.10A mm. The shot-peening pressure is 0.5MPa, the shot-peening coverage is 120%, and the shot-peening time is 8 minutes; the shot-peening shot is cast steel shot with a hardness of 50HRC.

[0046] According to the test method of Example 1, the hard rock cutter ring in Example 2 is tested. ...

Embodiment 3

[0048] Fix the hard rock cutter ring on the rotating shaft according to the coincidence of the central axis of the hard rock cutter ring with the central axis of the rotating shaft;

[0049] Use 1212P shot blasting machine to shot peen the blade of hard rock cutter ring. The shot peening conditions are: the diameter of the cutter ring is 17in, and the rotating shaft rotates around the axis at a speed of 15rpm; A 16mm spray gun is used to shot peen the edge area of the hard rock cutter ring of the shield machine (the position extending 32mm from the edge boundary) using the runner injection method, wherein the injection incident angle is 100°, and the shot peening intensity is 0.11A mm. The shot peening pressure is 0.6MPa, the shot peening coverage rate is 150%, and the shot time is 9 minutes; the shot peening shot is cast steel shot with a hardness of 48HRC.

[0050] The hard rock cutter ring in embodiment 3 is tested according to the test method of embodiment 1. After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com