Prediction method for microstructure evolution of shot peening strengthening material

A technology of shot peening and tissue evolution, which is applied in computer material science, design optimization/simulation, instruments, etc., can solve the problems of difficult microstructure observation, insufficient material structure refinement mechanism, and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the effect of the present invention will be further described:

[0025] This embodiment includes the following steps:

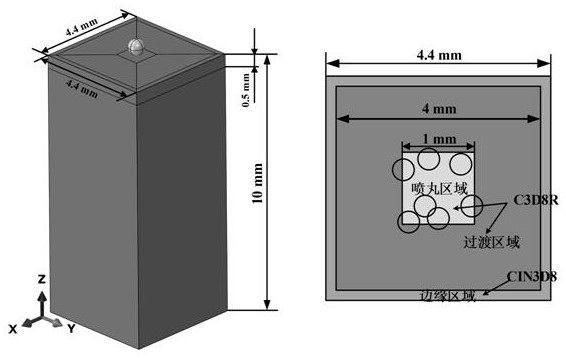

[0026] Step 1. In the process of shot peening, simplify the situation that the surface of the metal parts is continuously impacted by the shot flow, and use the ABAQUS platform to establish a three-dimensional shot peening model of the spherical projectile impacting the target.

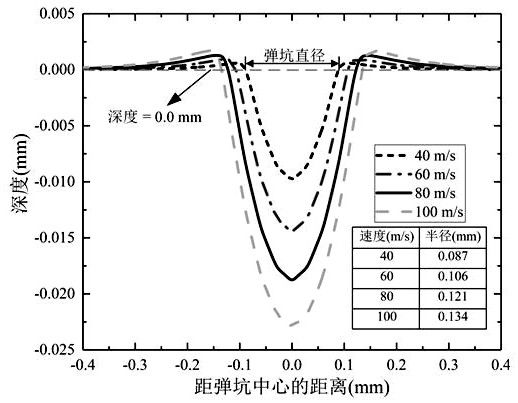

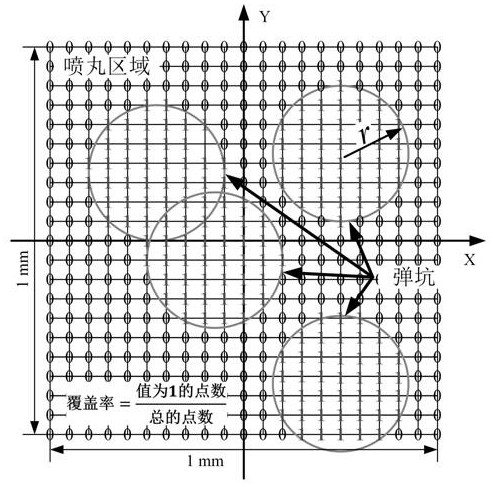

[0027] See the literature "Investigation on the effect of shot peening coverage on the surface integrity", Lin, Applied Surface Science, vol.489, pp.66-72 ("The impact of shot peening coverage on the surface integrity", Lin, Applied Surface Science , Vol. 489, 2019, pp. 66-72) records that the modeling method of the target body is as follows: the shot peening area in the middle of the target body is divided by a grid with a small enough size to ensure the calculation accuracy of the model, and the Infinite elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com