Slicing device for wood block

A technology for slicing devices and wood blocks, which can be used in wood processing equipment, forming/shaping machines, manufacturing tools, etc., and can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

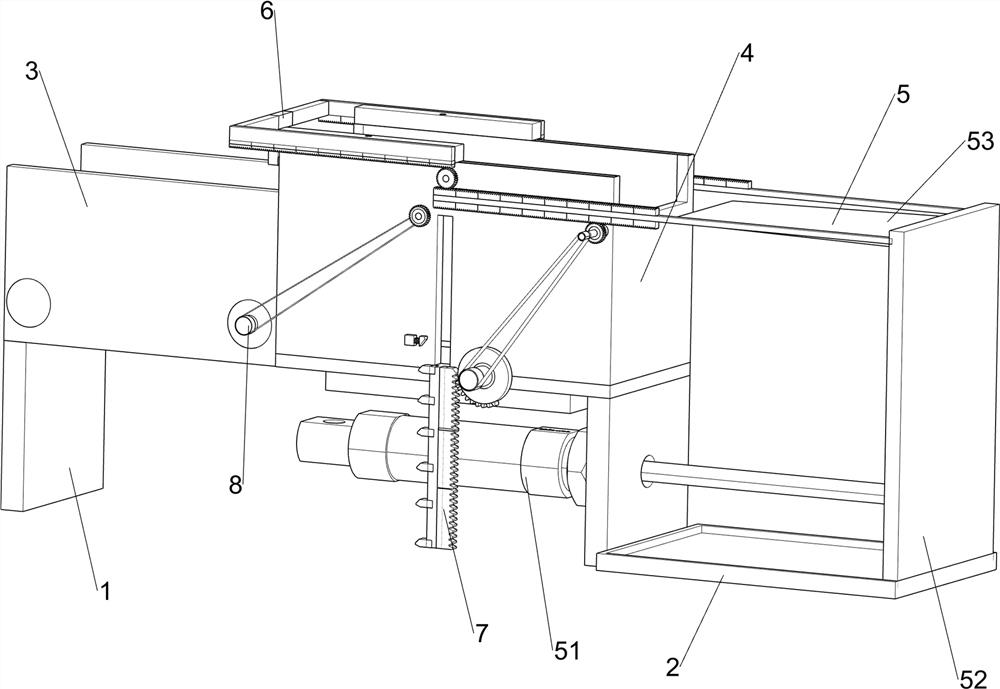

[0024] A device for slicing wood blocks, such as Figure 1-5 and Figure 8-9 As shown, it includes a support plate 1, a sliding frame 2, a mounting plate 3, a discharge box 4, a cutting mechanism 5 and a push-out mechanism 6, and the front and rear sides of the left side of the discharge box 4 are connected with a mounting plate 3, two The left side of mounting plate 3 bottoms is connected with support plate 1, and the right side of discharge box 4 bottoms is also connected with support plate 1, and the right side lower part of right support plate 1 is connected with slide frame 2, and on slide frame 2 A cutting mechanism 5 is provided, and a push-out mechanism 6 is arranged on the discharge box 4, and the push-out mechanism 6 is connected with the cutting mechanism 5 through transmission.

[0025] The cutting mechanism 5 includes a cylinder 51, a connecting slide 52 and a cutter 53, the top of the sliding frame 2 is slidably connected with a connecting slide 52, the upper le...

Embodiment 2

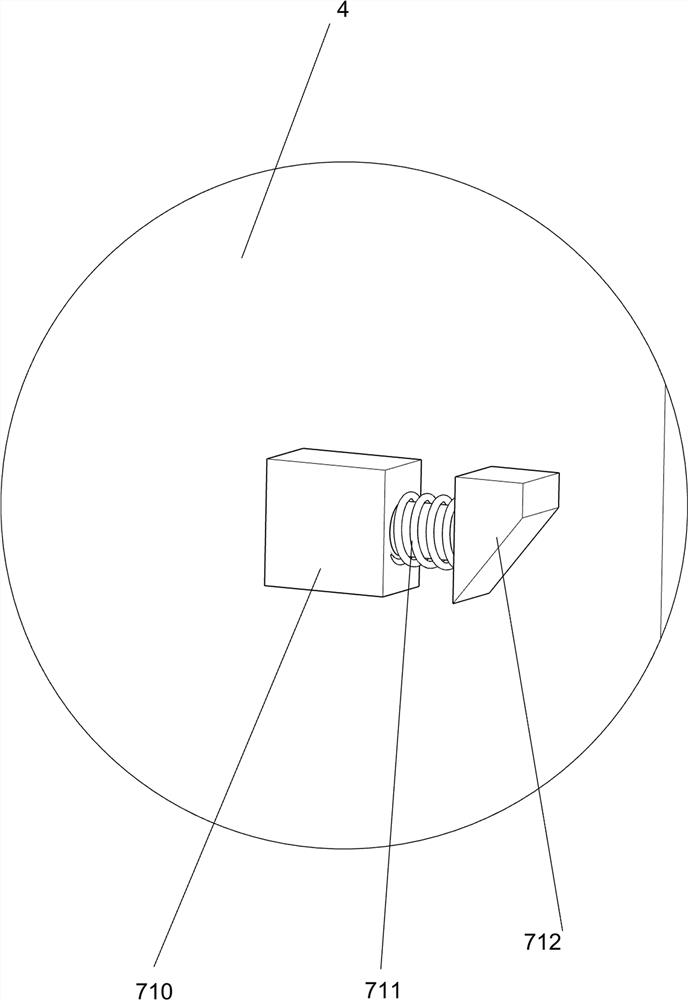

[0029] On the basis of Example 1, such as Figure 5-7 As shown, it also includes a lifting mechanism 7, and the lifting mechanism 7 includes a second rack 71, a second transmission rod 72, a first one-way gear 73, a first belt transmission group 74, a third transmission rod 75, and a half gear 76. , the third rack 77, the second wedge block 78, the push plate 79, the connecting block 710, the second spring 711 and the third wedge block 712, the bottom of the left side of the first transmission rod 61 on the front side is connected with the second rack 71 , the front side of the discharge box 4 on the lower side of the second rack 71 is rotatably connected with a second transmission rod 72, and the second transmission rod 72 is connected with a first one-way gear 73, and the first one-way gear 73 is connected to the second gear The bar 71 is engaged, and the front side of the discharge box 4 on the lower left side of the second transmission rod 72 is rotatably connected with a ...

Embodiment 3

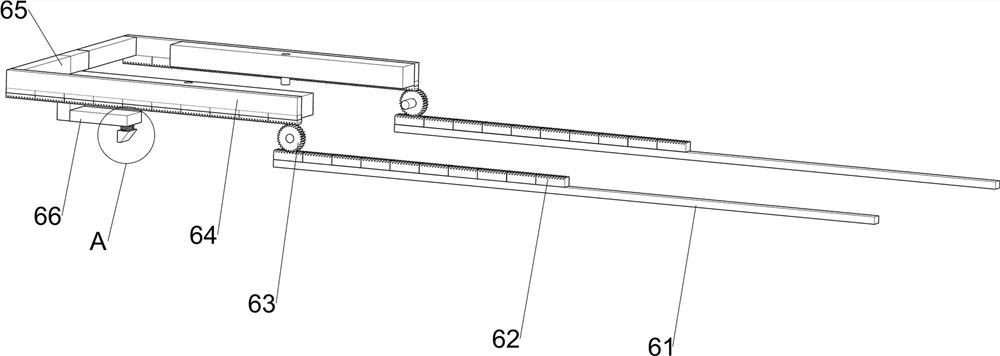

[0032] On the basis of Example 2, such as Figure 8-9 As shown, transport mechanism 8 is also included, and transport mechanism 8 includes second one-way gear 81, second belt transmission group 82, fourth transmission rod 83, roller 84 and conveyer belt 85, front side pinion 63 bottom left The front side of the discharge box 4 is rotatably connected with a second one-way gear 81, the second one-way gear 81 meshes with the second rack 71, and two fourth transmission gears are rotatably connected between the inner sides of the two mounting plates 3. Rod 83, two fourth transmission rods 83 are symmetrical left and right, the fourth transmission rod 83 is connected with a roller 84, is connected with a conveyor belt 85 between the two rollers 84, the right fourth transmission rod 83 and the second one-way gear 81 A second belt drive group 82 is connected between the drive shafts.

[0033] Chips move to the left and fall on the conveyor belt 85 thereupon, the second tooth bar 71 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com