A vase changing device for ceramic manufacturing

A technology for vases and ceramics, which is applied in the field of vase opening equipment for ceramic manufacturing, which can solve the problems of high labor intensity and low efficiency, and achieve the effects of reducing operation difficulty, improving work efficiency, and ensuring bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

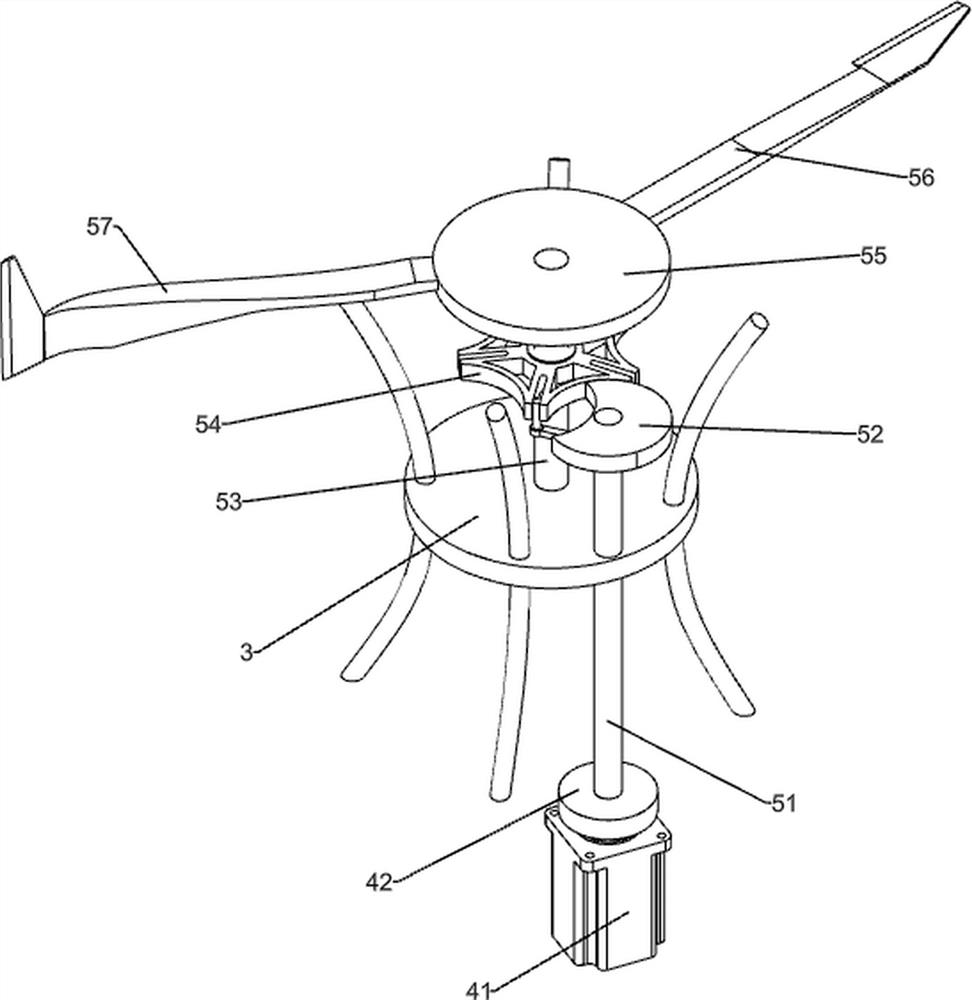

[0023] A device for changing mouths of vases for ceramic manufacture, such as Figure 1-3 As shown, it includes a stand 1, a support plate 2, a frame 3, a rotating assembly 4 and a replacement assembly 5, a support plate 2 is installed on the right side of the bottom of the stand 1, a frame 3 is connected to the right side of the top of the stand 1, and the stand 1 and the A rotating assembly 4 is installed between the support plates 2 , and a replacement assembly 5 is installed between the platform 1 and the frame 3 .

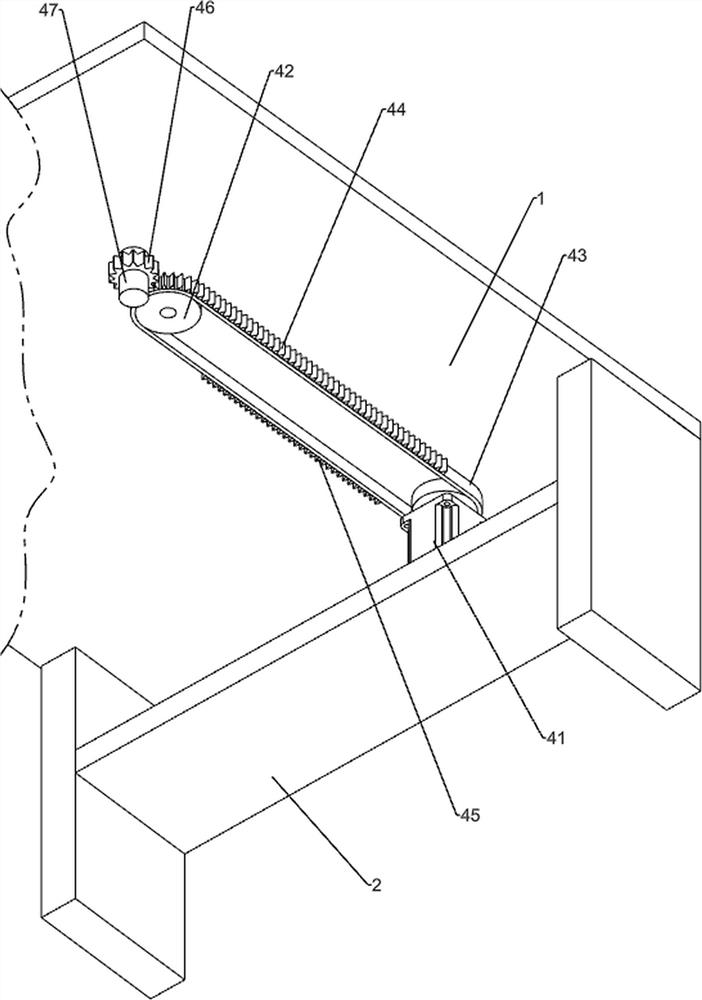

[0024] The rotating assembly 4 includes a reduction motor 41, a runner 42, a belt 43, a long rack 44, a short rack 45, a transmission gear 46, a rotating rod 47 and a first rotating disk 48, and the support plate 2 is connected with a reduction motor 41, and the stand 1 The left and right sides of the bottom are rotatably equipped with runners 42, the runner 42 on the right is connected to the output shaft of the reduction motor 41, a belt 43 is connected betw...

Embodiment 2

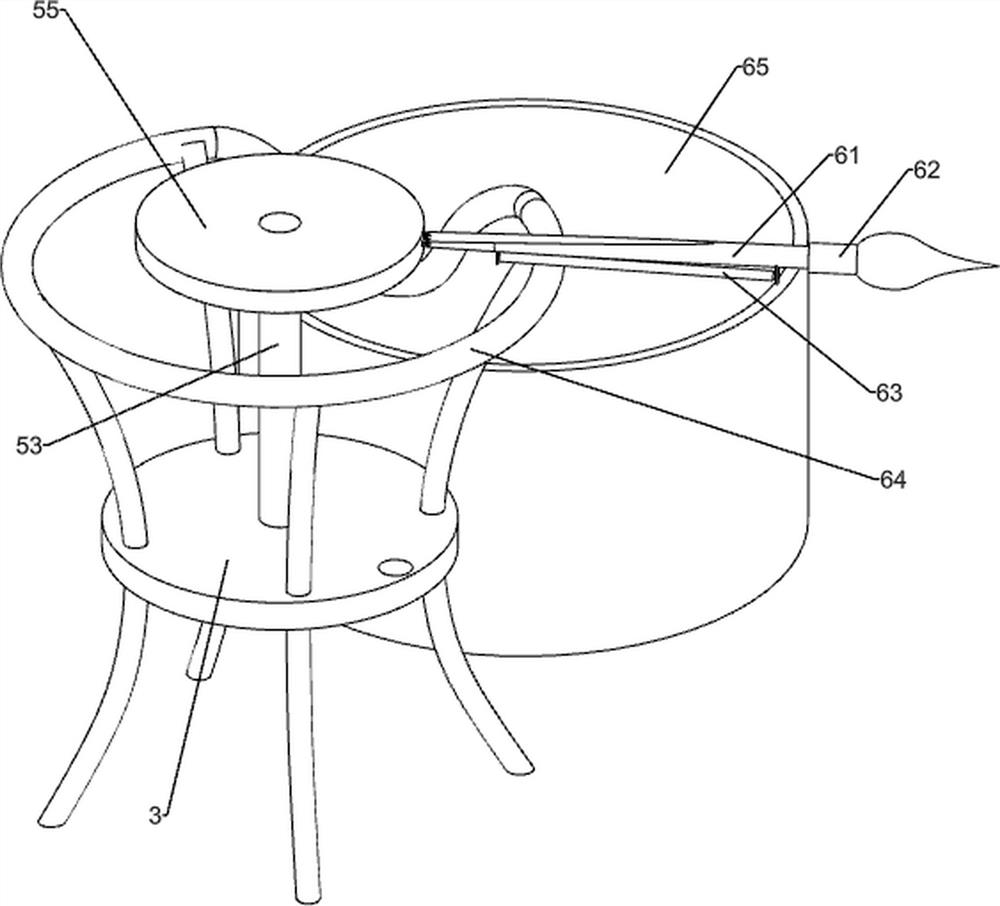

[0028] On the basis of Embodiment 1, as shown in 4, it also includes a brush assembly 6, and the brush assembly 6 includes a connecting rod 61, a dipping brush 62, a roller 63, a guide rail 64 and a charging bucket 65, the first The outer surface of the second turntable 55 is hingedly connected with a connecting rod 61, the tail end of the connecting rod 61 is connected with a dip brush 62 in a detachable manner, the bottom of the connecting rod 61 is connected with a roller 63, and the top of the frame 3 is connected with a guide rail 64, the roller 63 is in contact with the top surface of the guide rail 64, the rear side of the top of the stand 1 is connected with a charging bucket 65, and the rear portion of the guide rail 64 is concave.

[0029] Fill the charging barrel 65 with mud material for bonding. When the second turntable 55 rotates, the connecting rod 61 is driven to rotate, and the roller 63 rolls on the guide rail 64. When the roller 63 moves to the concave positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com