Bag making machine

A bag-making machine and bag-sealing technology, which is applied in bag-making operations, container manufacturing machinery, flexible container manufacturing, etc. Adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

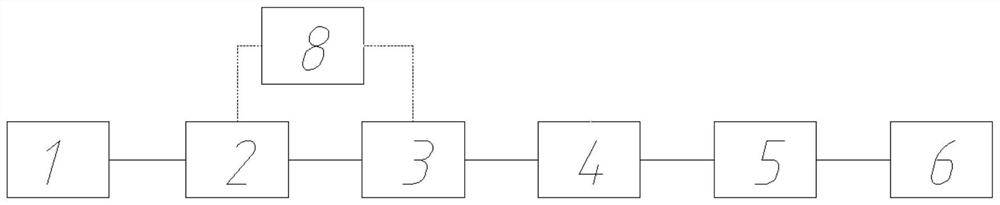

[0041] Such as figure 1 Shown is a kind of bag making machine, including sealing bag feeding device 1, sealing bag cutting device 2, side feeding device 8, side hot pressing device 3, material turning device 4, bottom side feeding device 5, bottom Edge hot-pressing device 6 and blanking cutting device (not shown in the figure), are used for cutting envelope 7, side hot-pressing, bottom edge hot-pressing and finally carrying out blanking cutting, complete the making of eight-side sealed bag ;

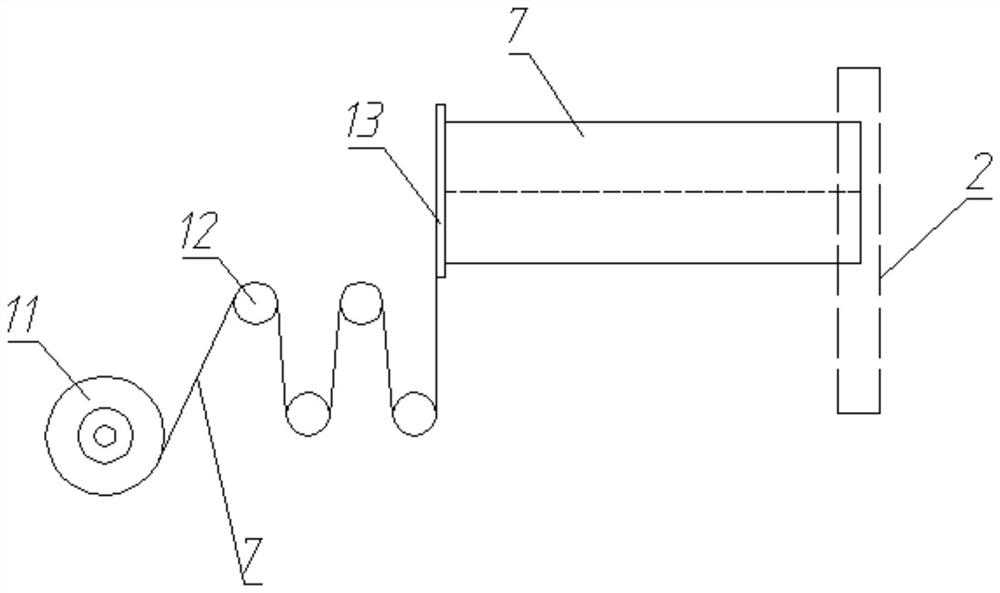

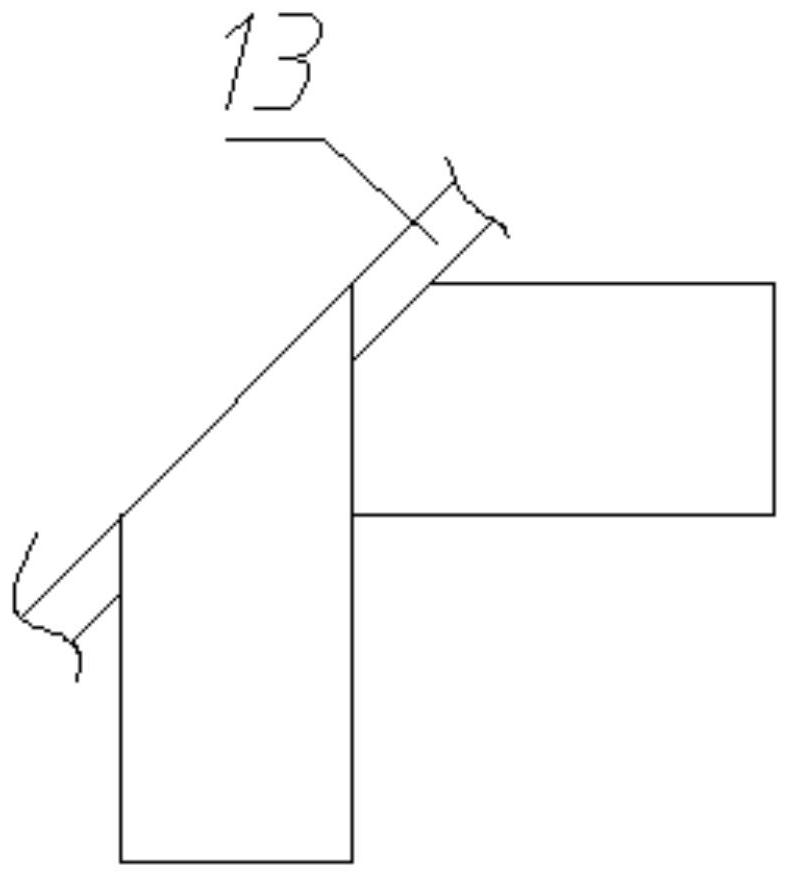

[0042] Such as Figure 2-3 Shown is the envelope feeding mechanism 1, the envelope feeding mechanism 1 includes a feed roller 11 for placing the envelope 7 and a tension roller 12 for tensioning the envelope 7, the tension roller 12 is up and down Set at intervals, the right side of the tension roller 12 is provided with an inclined turning roller 13, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com