High-temperature carburizing, slow-cooling, quenching and tempering heat treatment method for engineering machinery track pin bush

A heat treatment method and high-temperature carburizing technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of long carburizing time, intergranular oxidation of the metallographic structure on the surface of the carburized layer, and low temperature carburizing temperature. The effect of reducing intergranular oxidation, increasing carburizing speed, and good service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

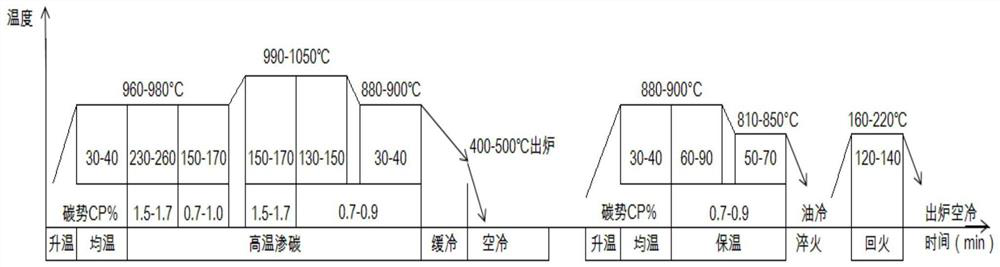

[0026] The best embodiment 1 is high-temperature carburizing and slow cooling in a double-chamber controllable atmosphere carburizing furnace, and its heat treatment process is as follows figure 1 shown. First, heat the construction machinery crawler pin sleeve workpiece prepared for high-temperature carburizing of low-carbon alloy steel, and automatically feed the carburizing carrier gas until the carburizing process is over; when the temperature reaches the first-stage carburizing temperature of 960-980°C , keep warm for 30-40min, then enter the first high-temperature carburizing and strong infiltration stage, keep warm for 230-260min, during which carburizing enriched gas and air are automatically introduced into the furnace to adjust the carbon potential in the furnace to maintain CP 1.5-1.7% ;After the intensive infiltration, it enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com