Installing structure for finished product type sewer pipeline

A technology for installing structures and pipes, applied to vertical pipes, building components, building structures, etc., can solve problems such as tile falling off or hollowing, safety and quality hidden dangers, and difficulty in ensuring quality, achieving easy operation and overall stability High, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

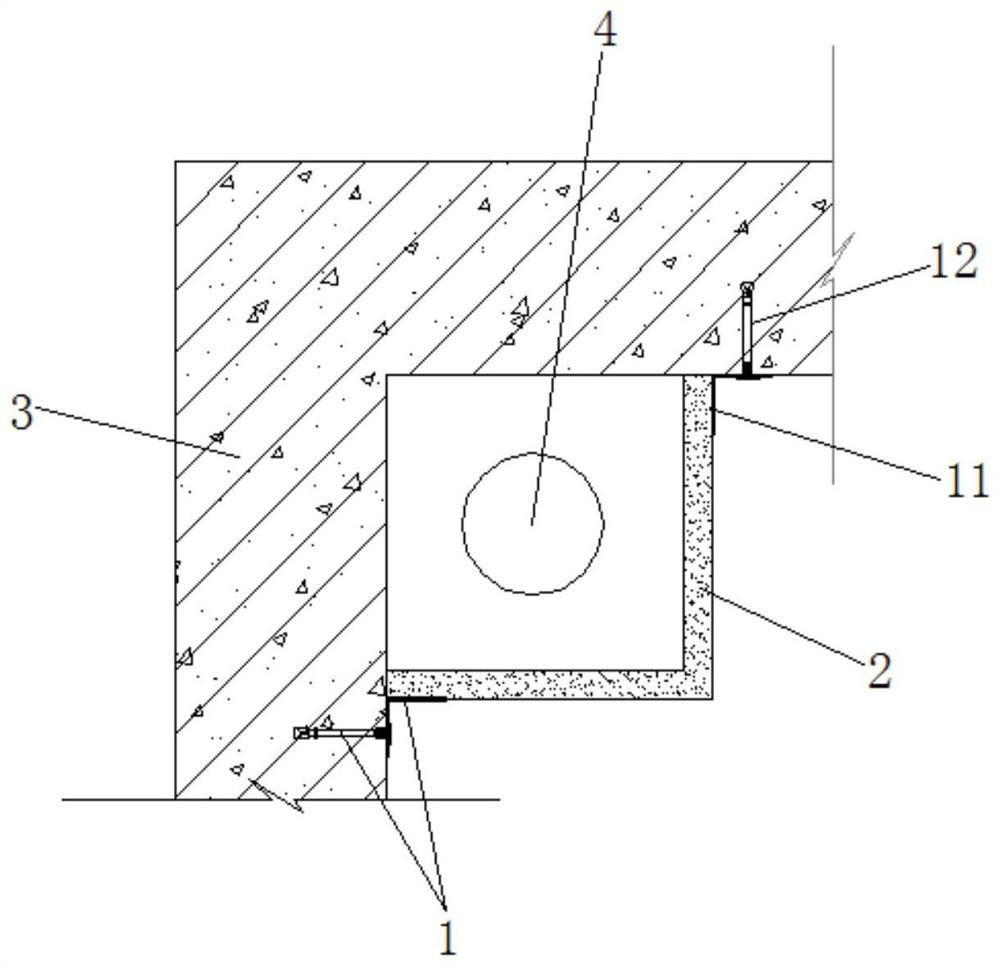

[0030] see figure 1 , the figure shows the installation structure of a finished sewer pipe provided by Embodiment 1 of the present invention, which mainly includes: a connection assembly 1, which includes a connector 11 and a fastener 12; an installation pipe 2, which is located on the base wall 3, and is covered on the outside of the sewer pipe 4, and the two sides of the installation pipe 2 are connected to the base wall 3 through the connection assembly 1; the connector 11 is bonded to the outer wall of the installation pipe 2, and the connector 11 is connected with the base wall 3 through fasteners 12; the installation pipe 2 is a finished concrete pipe; ceramic tiles are laid on the outer wall of the installation pipe 2.

[0031] The installation structure of a finished sewer pipe provided in this embodiment mainly includes a connection assembly 1 and an installation pipe 2. The installation pipe 2 is a finished pipe and can be directly installed on the outside of the sew...

Embodiment 2

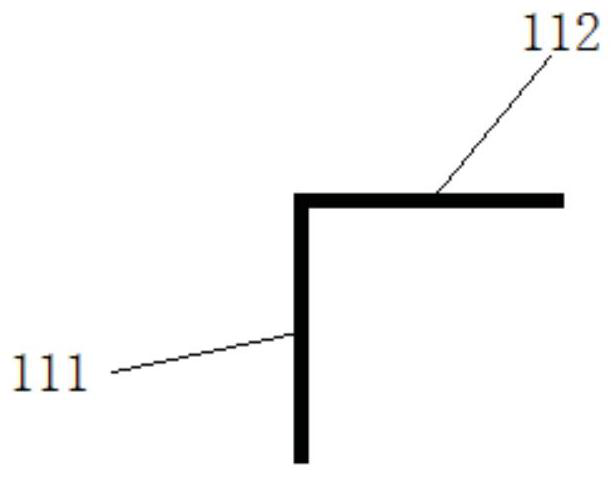

[0039] see Figure 1-2 , the figure shows the installation structure of a finished sewer pipe provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: connecting piece 11 It includes a first connecting plate 111 and a second connecting plate 112 perpendicular thereto, the first connecting plate 111 is bonded to the outer wall of the installation pipe 2, and the second connecting plate 112 is connected to the base wall 3 through fasteners 12; The connecting piece 11 is "L" shaped. Among them, the connector 11 is a galvanized corner bracket; the specification of the galvanized corner bracket is 60×60×20 mm. Through the setting of the above structure, the connection between the installation pipe 2 and the base wall 3 is facilitated, and the connection effect between the two is improved.

Embodiment 3

[0041] see figure 1 , the figure shows the installation structure of a finished sewer pipe provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: fasteners 12 is a metal expansion bolt; the specification of the metal expansion bolt is M6×80mm. Through the setting of the above-mentioned structure, the installation is convenient, and at the same time, the connection strength between the connecting piece 11 and the base wall 3 can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com