Single Ring Locknut Assemblies

A technology of lock nut and ring sleeve type, which is applied in the direction of nuts, threaded fasteners, screws, etc., and can solve problems such as large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

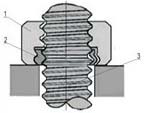

[0017] Embodiment 1: as figure 1 What is shown is a single structure of a ring-type locknut, which is provided with a frustum-shaped internal thread cavity on the nut, making it a cavity nut 1 as a whole, and built into the cavity of the cavity nut 1 Set the ring member 2 of the truncated cone-shaped internal and external thread that is matched with it. Here, the taper of the tapered thread is set to 3 degrees, and between the internal thread and the external thread of the ring member 2, a Based on the elimination of the eccentric value of the standard thread fit clearance, that is, this value is the specification size of the nut—the gap between the internal thread and the bolt 3, and the fit clearance between the frustum-shaped internal thread and the 2-cone external thread of the ring member is also taken into account. When the ring member 2 is screwed into the bolt together with the nut for locking, it can achieve the comprehensive structural effect of the eccentricity of t...

Embodiment 2

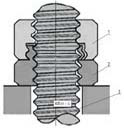

[0018] Embodiment 2: as figure 2 The structure shown is a slightly changed ring-type locknut, which is actually designed according to the standard size of the nut, and the structural characteristics of the concave cavity nut 1 in this embodiment and the embodiment 1 have not changed in any way , just put the annular member part in embodiment 1 on another nut, thereby forming the boss nut 2, in the specific implementation, the structure and function effect of the double nut is slightly different from that of embodiment 1, but each has its own advantages. The advantage is that the overall structure and efficacy are also worthy of recognition, and can be selected for different needs; if this embodiment is to enhance the actual effect, it is obvious that it can be designed as a non-standard product by increasing the size according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com