Heat-not-burn cigarette, smoking set and application

A heat-not-burn and cigarette technology, which is applied in the field of tobacco smoking sets, can solve problems such as insufficient heating, insufficient smoke release, and rising smoke temperature, and achieves insufficient heating area, significant heating volatilization effect, and smoke release The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

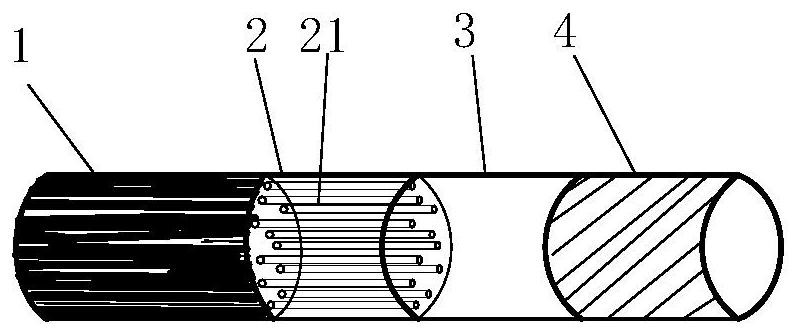

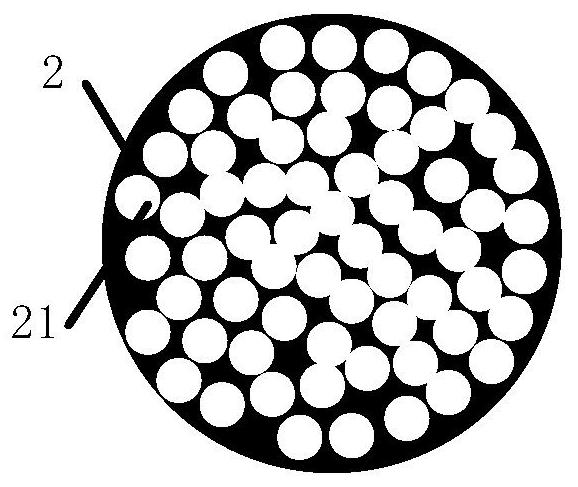

[0037] A heat-not-burn cigarette of this embodiment, such as figure 1As shown, it includes a smoking section 1, a supporting section 2, a cooling section 3 and a filtering section 4 arranged in sequence. The tobacco in the smoking section 1 is reconstituted tobacco shreds arranged in an orderly manner, and is rolled with flavored cigarette paper. Forming; the support section 2 is made of polyimide PI polymer material, and the support section 2 is provided with a rod-shaped porous structure 21 along the axial direction. This porous structure 21 is the main air intake channel. The rod-shaped porous structure of this embodiment The number of intake passages is 30, and the cross-section of the intake passages includes one or more combinations of circular, square, quincunx, star or irregular shapes. The intake passages of this embodiment are as follows image 3 As shown, the space in the cross section of the support section is circular, its volume hollowness is 60%, and the diamete...

Embodiment 2

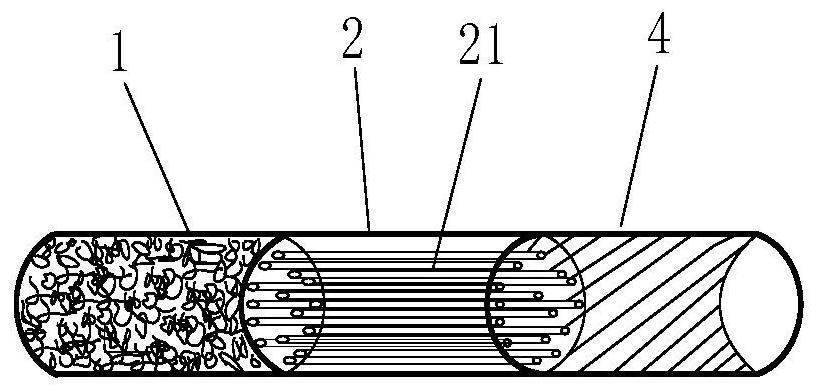

[0042] A heat-not-burn cigarette of this embodiment, such as figure 2 As shown, it includes a smoking section 1, a supporting section 2 and a filtering section 4 arranged in sequence.

[0043] The smoking section 1 is a mixture of shredded tobacco, expanded shreds and reconstituted tobacco leaves arranged in disorder, and is rolled and shaped with ordinary cigarette paper; the supporting section 2 is made of polyether ether ketone PEEK polymer material, and the supporting section 2 There is a rod-shaped porous structure 21 extending axially. This porous structure is the air intake channel. One or more combinations, the gap in the cross-section of the support section in this embodiment is rhombus, the maximum gap distance between the rhombus and the circle is 0.12mm, and its volume hollowness is 70%. The filter section 4 is a hollow filter rod made of acetate fiber.

[0044] Such as figure 2 As shown, the smoking section 1, the supporting section 2 and the filtering sectio...

Embodiment 3

[0048] A heat-not-burn cigarette stick in this embodiment includes a smoking section 1 , a supporting section 2 and a filtering section 4 arranged in sequence.

[0049] The tobacco in the smoking section 1 is reconstituted tobacco shreds arranged in an orderly manner, and rolled with aluminum foil composite cigarette paper; the supporting section 2 is made of polyetherimide PEI polymer material, and the axial direction of the supporting section 2 A rod-shaped porous structure 21 is extended, and this porous structure is the air intake passage. There are 30 air intake passages in this embodiment, and the cross-section of the support section is a mixture of rhombus and circle. The maximum gap distance between rhombus and circle is 0.12 mm, its volume hollowness is 50%. The filter section 4 is a hollow filter rod made of acetate fiber. Such as figure 2 As shown, the smoking section 1, the supporting section 2 and the filtering section 4 are simultaneously rolled by ordinary ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com