Shale gas fracturing method and device

A gas pressure and shale technology, applied in the field of shale gas fracturing methods and devices, can solve the problems of lack of simple and low-cost drilling and fracturing methods, delay of project progress, poor fracturing effect, etc., and achieve The effect of expanding the effective fracturing range, strong applicability, and saving working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

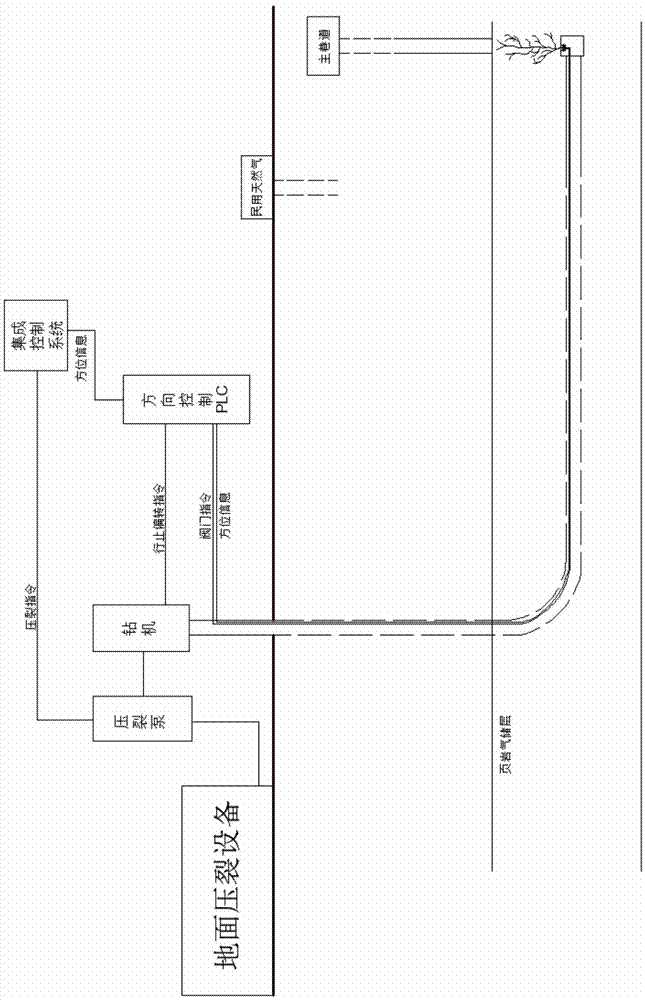

[0016] A shale gas fracturing method and device, which mainly includes an integrated control system, ground fracturing equipment, direction control PLC, directional drilling rig, fracturing pump, shale gas fracturing drill bit, etc.; the equipment and systems are interconnected , with the integrated control system and direction control PLC as the core to issue information and instructions.

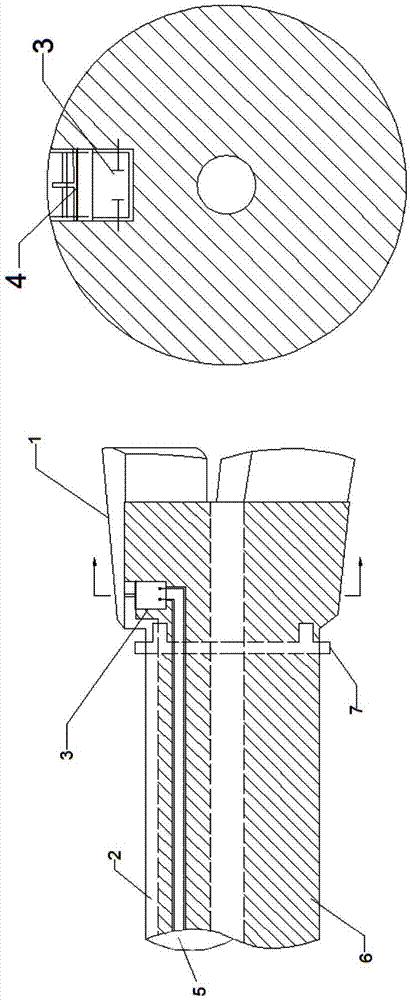

[0017] The shale gas fracturing drill bit mainly includes a three-wing drill bit 1, a high-pressure gas conduit 2, a direction control system 3, an electromagnetic numerical control valve 4, a conductive wire and an insulating layer 5, a drill pipe part 6 connected with the drill bit, and a steering Joint 7; the high-pressure gas conduit 2 maintains a safe wall thickness, and the side opening on the drill bit 1 adopts a T-shaped opening to commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com