Shock absorber for new energy automobile

A technology of new energy vehicles and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., and can solve the problem of large rebounding force of shock absorbers, limited effect, and affecting the use of shock absorbers, etc. problem, to achieve stable shock absorption and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

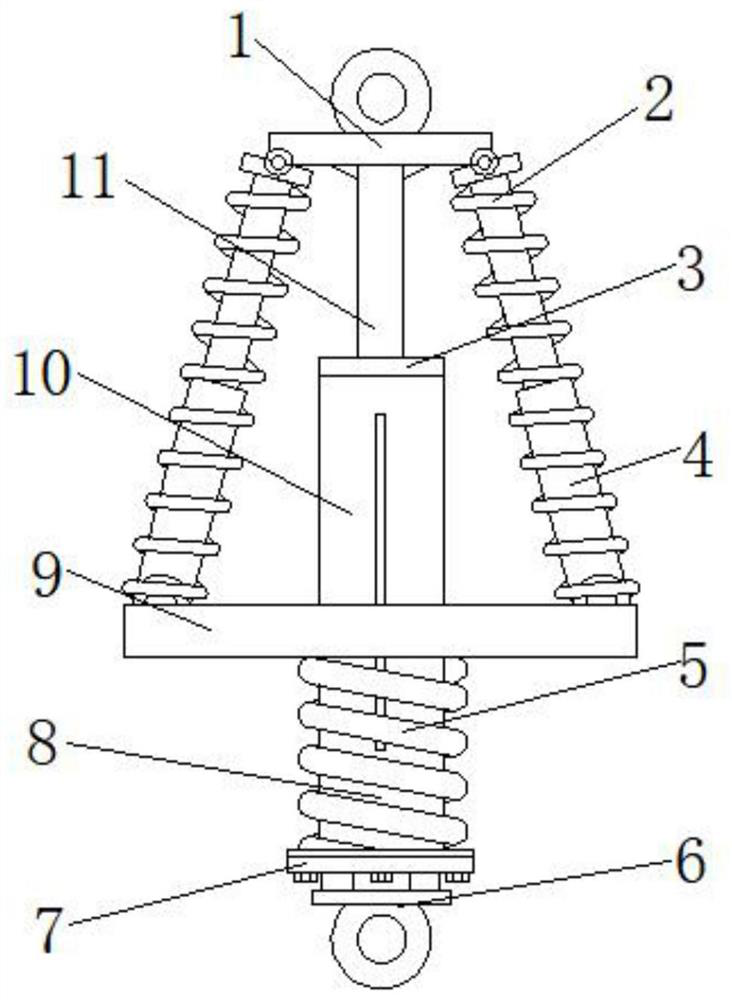

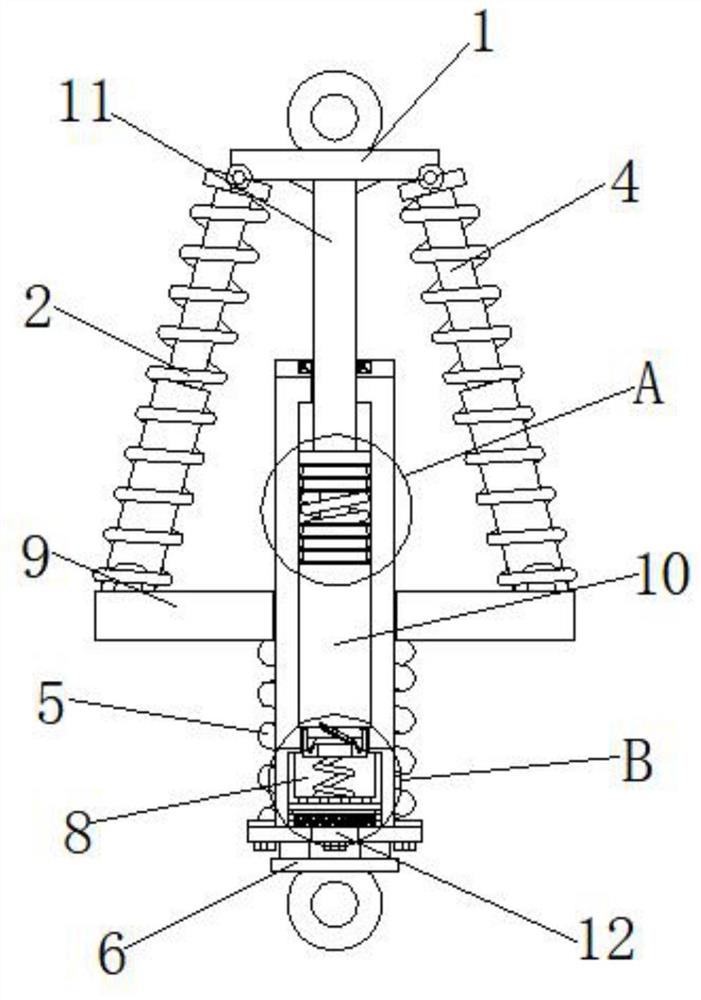

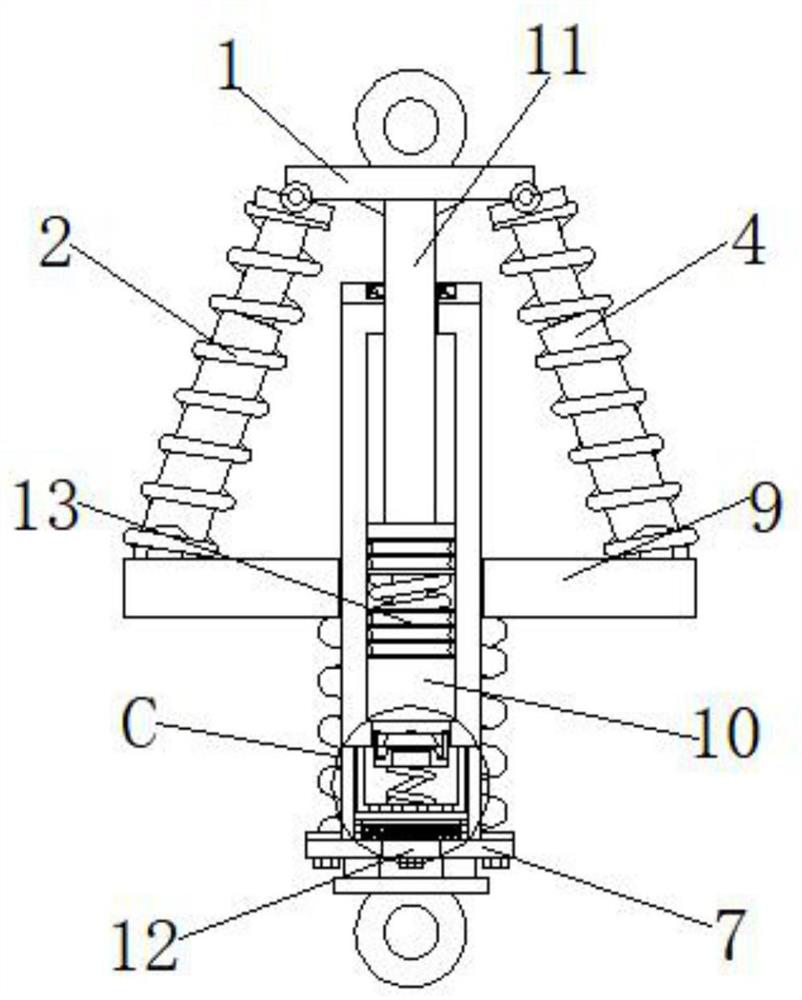

[0033] Example 1, such as figure 1 , 2 , 5, 6, 7 and 8, when the shock absorber for new energy vehicles is stressed, the movable rod 11 gradually moves to the inside of the cylinder body 10, pushing the piston assembly 13 down inside the cylinder body 10, forcing the piston assembly 13 The pressure in the bottom space increases, the telescopic rod 133 shortens, and the first piston 134 and the second piston 132 approach each other. When the pressure in the space below the second piston 132 is high, the sealing plug 806 is forced to move downward, so that the installation The through hole of the ring 801 is blocked, so that the air inside the cylinder body 10 runs from the through hole of the installation ring 801 into the interior of the inner installation chamber 805, and then passes through the through hole 804, the filter screen and the port 12 and then is discharged to the external environment In the process, the lifting rod 4 is shortened by force, the first spring 2 is ...

Embodiment 2

[0034] Example 2, such as Figure 1-8 As shown, when the second spring 5 and the first spring 2 release the elastic potential energy, the upper mounting seat 1 and the movable rod 11 are pushed up, and the piston assembly 13 moves up inside the cylinder body 10, so that the space under the piston assembly 13 is under negative pressure. state, forcing the outside air to enter the push-off sealing cover 809 and enter the interior of the cylinder 10, so that the movable rod 11, the piston assembly 13 and the cylinder 10 together play the role of syringe pumping, which greatly alleviates the second The elastic potential energy released by the spring 5 and the first spring 2 prevents the large rebound force of the shock absorber from making the entire new energy vehicle more bumpy.

[0035] Working principle: When the shock absorber for new energy vehicles is stressed, the movable rod 11 gradually moves to the inside of the cylinder body 10, pushing the piston assembly 13 down insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com