Electrolytic flotation tank combined drying foam layer circulation post-processing device

A post-processing device and electrolytic air flotation technology, which is applied in the directions of dry gas arrangement, flotation water/sewage treatment, grease/oily substance/suspton removal device, etc. The problem of narrow electrolysis area and other problems can achieve the effect of good after-treatment effect, low cost and enhanced utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

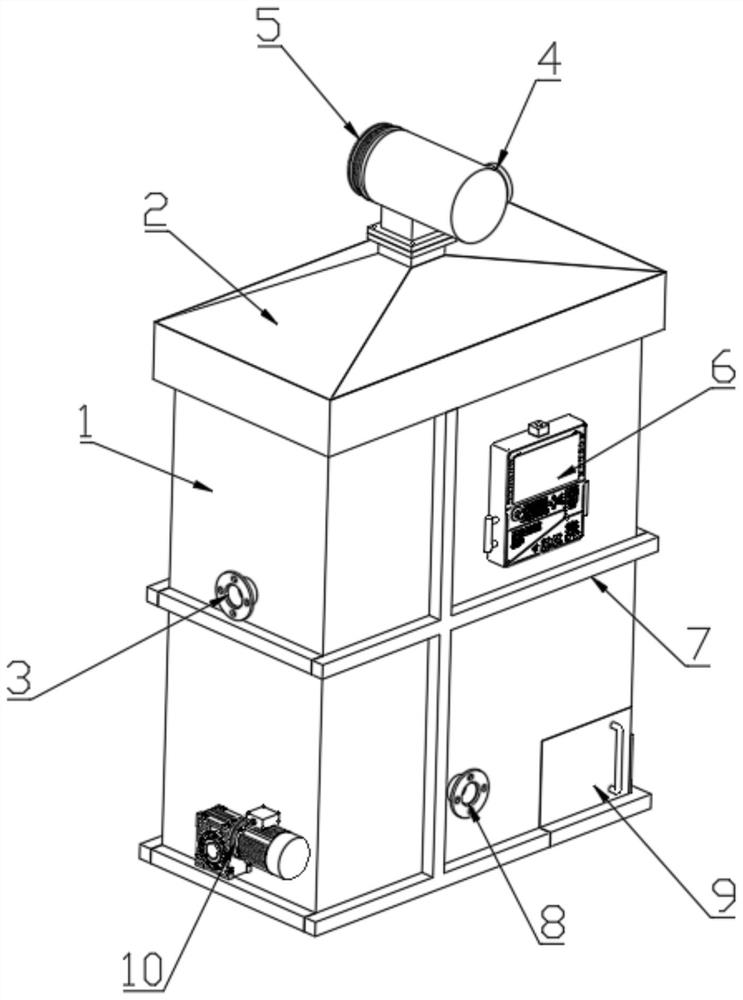

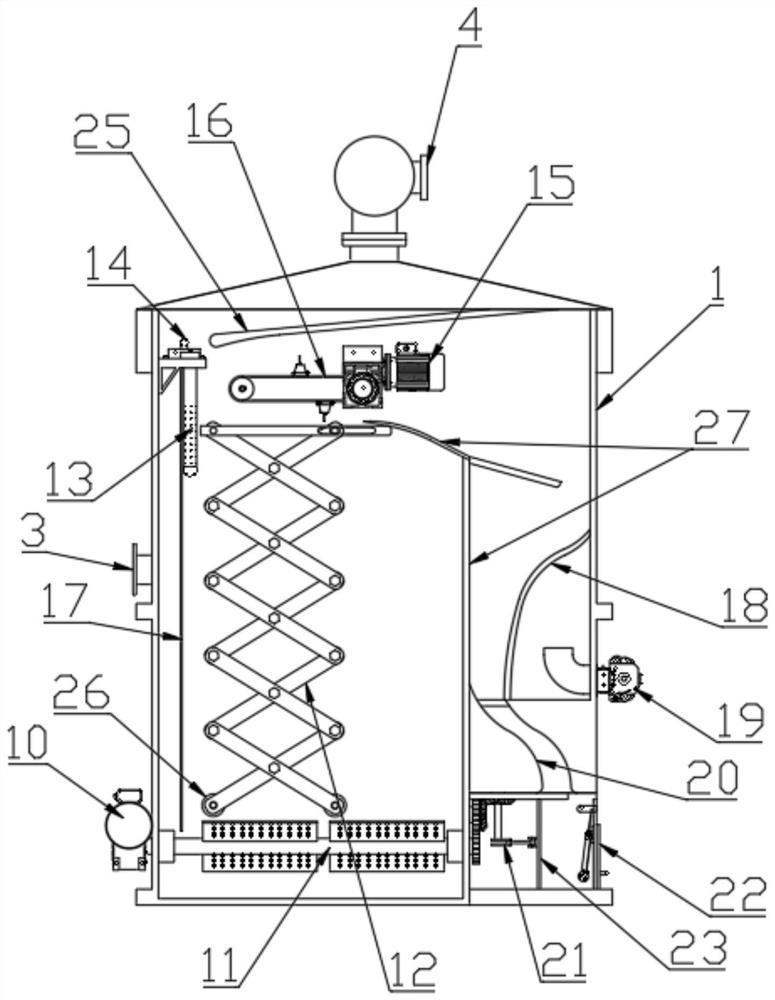

[0037] Such as figure 1 , 2 As shown, an electrolytic air flotation pool combined with a dry foam layer circulation post-processing device includes a frame mechanism, an electrolytic air flotation chamber, a drying chamber, a slag discharge box 9, and a control panel 6.

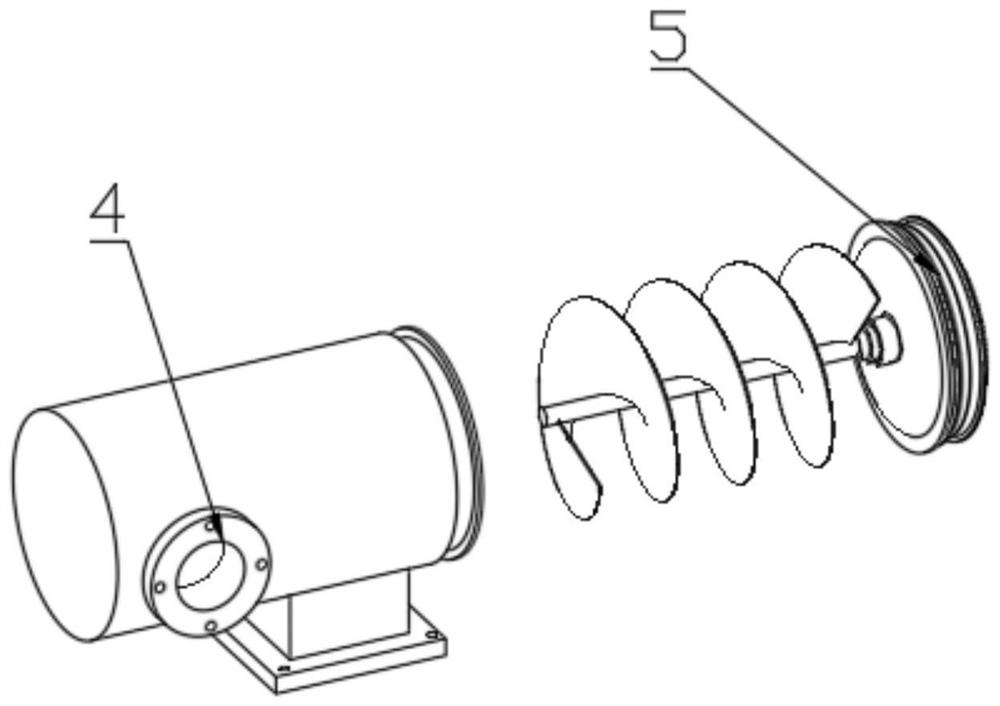

[0038] Such as figure 2 As shown, the frame mechanism includes a housing 1 and a top cover 2, the bottom of the housing 1 is provided with a base, and the top and the top cover 2 form a closed chamber, which is separated by a partition 27 into an electrolytic air flotation chamber, a drying The slag box 9 is connected under the drying chamber; the top cover 2 shrinks from bottom to top, a hot ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com