Deicing method

A technology for deicing and ice trays, which is applied in the fields of ice manufacturing, ice storage/distribution, thermal analysis of materials, etc., can solve the problems of low ice production and high energy consumption, save energy, improve ice production, and deicing time. Node Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

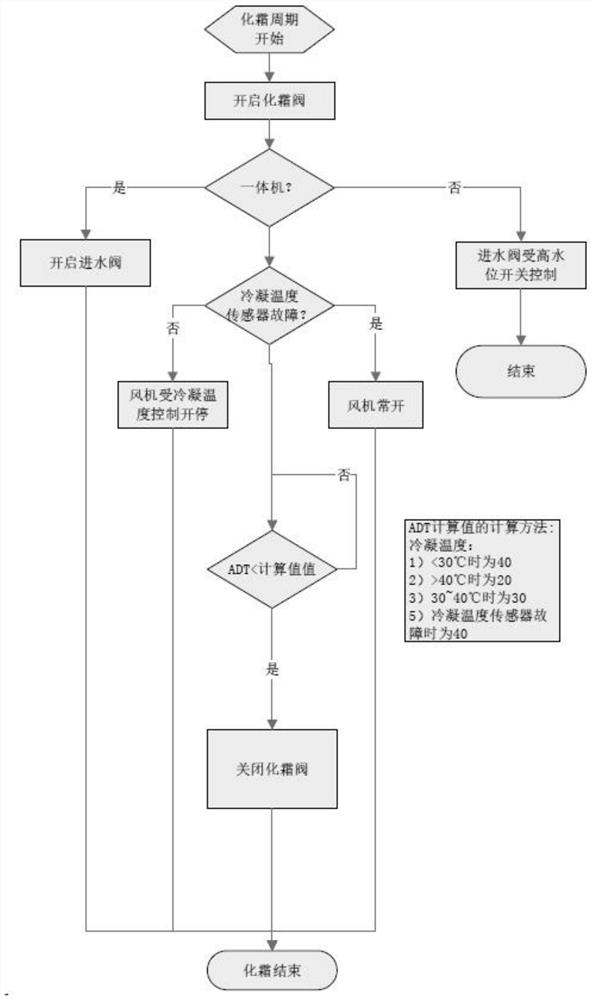

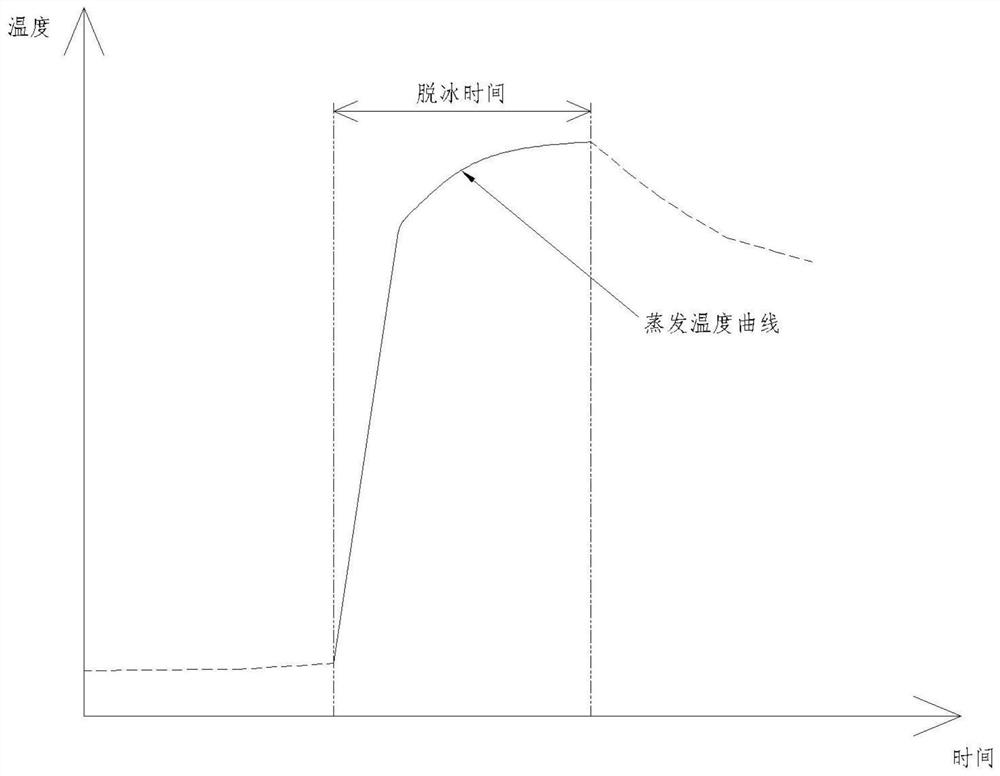

Method used

Image

Examples

experiment example 1

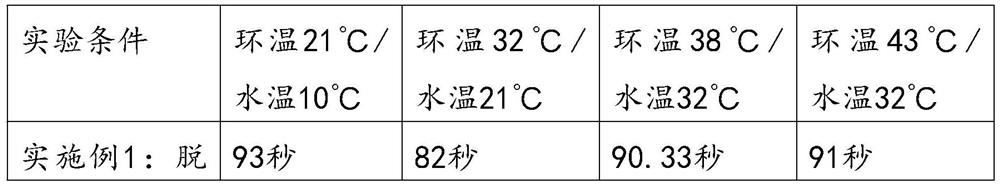

[0050] Experimental Example 1: The above method is used for the ice maker, and the first fixed time is set to 1 second; the experimental conditions of Experimental Example 11: the operating environment temperature of the ice maker (abbreviated as ambient temperature) is 21°C, and the inlet water temperature (abbreviated as water temperature) The temperature is 10°C, the number of continuous collection of evaporation temperature is 40 times, and the measured deicing time is 93.00 seconds; the experimental conditions of Experimental Example 12: the ambient temperature is 32°C, the water temperature is 21°C, and the number of continuous collection of evaporation temperature is 30 times , the measured deicing time is 82.00 seconds; the experimental conditions of Experimental Example 13: the ambient temperature is 38°C, the water temperature is 32°C, the number of continuous collection of evaporation temperature is 30 times, and the measured deicing time is 90.33 seconds; Experimenta...

Embodiment 1

[0052] The deicing time obtained from the experimental results of Example 1 and Comparative Example 1 is compared in the following table.

[0053]

[0054]

[0055] Experimental comparison 2:

experiment example 2

[0056] Experimental Example 2: The above-mentioned method of the present invention was adopted for an ice maker. The ambient temperature of the ice maker was 32° C., and the water temperature of the ice-making water in the ice maker was 21° C., and the amount of ice produced after the ice maker worked for 24 hours was measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com