Blasting construction technology for water diversion tunnel rock plug with high water permeability

A construction process and technology for diversion tunnels, applied in blasting and other directions, can solve the problems of threatening personnel safety, prone to leakage, affecting the effect of water intake in diversion tunnels, etc., and achieve the effect of ensuring personnel safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

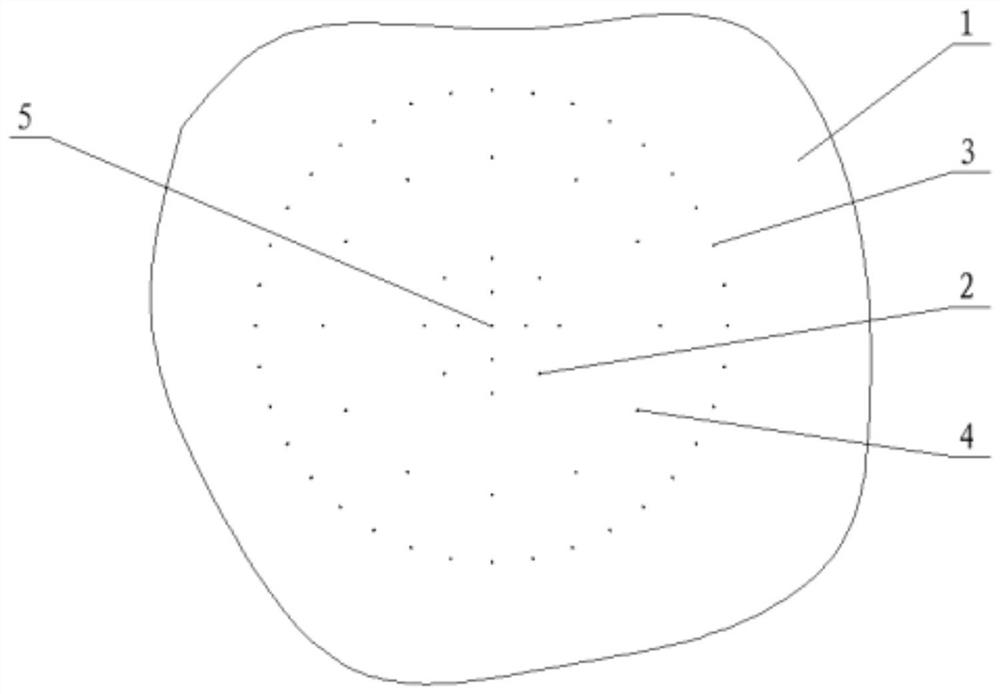

[0025] like figure 1 As shown, the present invention provides a construction technique for blasting a water diversion tunnel strong seepage rock plug, comprising the following steps:

[0026] Step 1: Excavate underground earth and stones in the area adjacent to the reservoir to form a water diversion tunnel. The earth and rocks between the end section of the water diversion tunnel and the inner wall of the reservoir form a rock plug. , investigate and obtain the volume of the rock plug as V, and then excavate earth and rocks in the water diversion tunnel to form a slag collection pit. The volume of the slag collection pit is not less than 3.2 times the volume of the rock plug;

[0027] Step 2: Use a drilling machine to drill several cut holes 2, several auxiliary holes 4 and several pre-splitting holes 3 on the blasting surface 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Rate | aaaaa | aaaaa |

| Fierceness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap