Macadam seal oil flooding degree testing method and asphalt consumption determining method

A technology of crushed stone seal and test method, which is applied in the direction of material inspection products, etc., can solve the problems of large seal production area, inability to detect the degree of asphalt oil bleed, and high production difficulty, so as to facilitate indoor test operation and simple test method Easy to implement, eliminates the effect of high subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

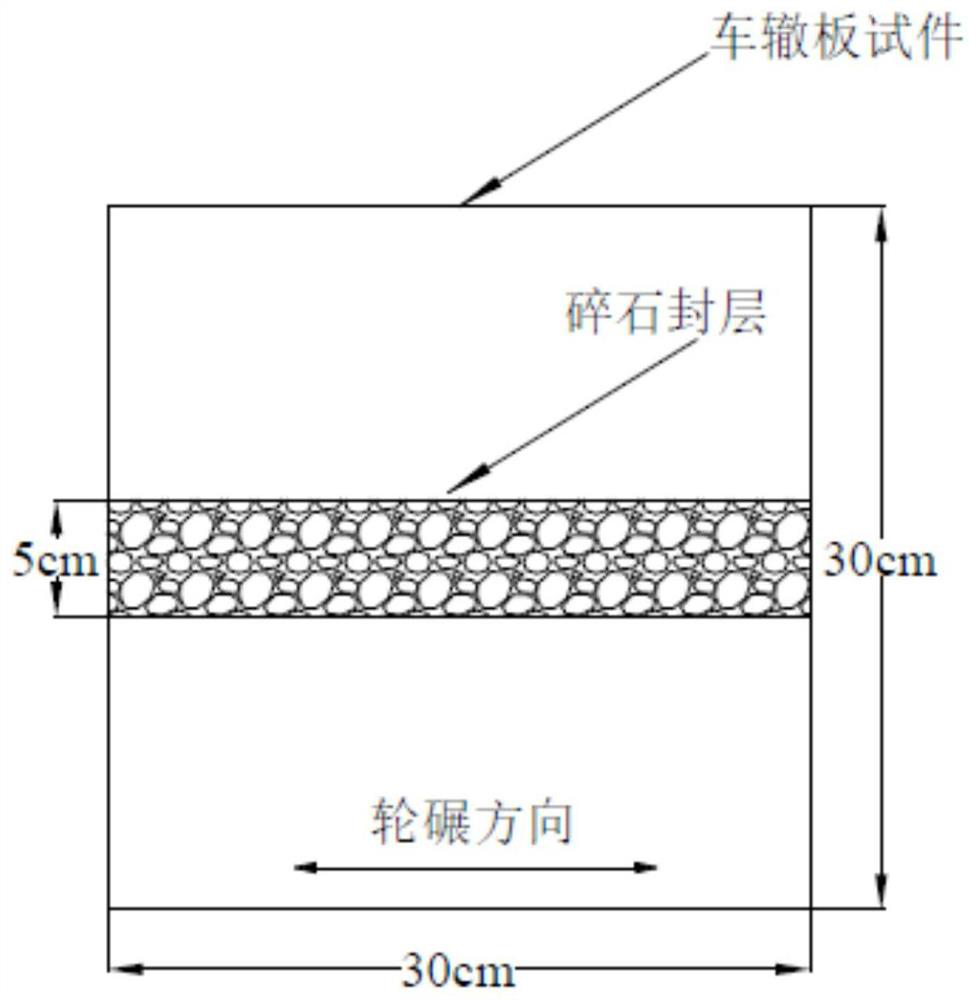

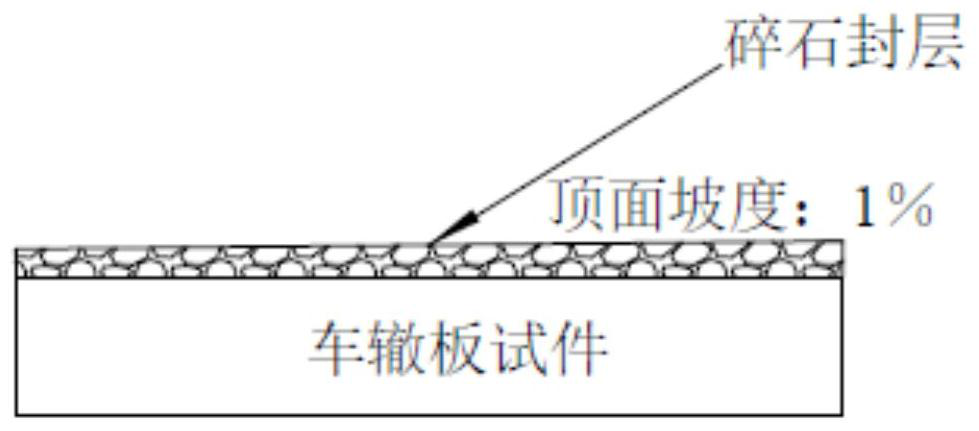

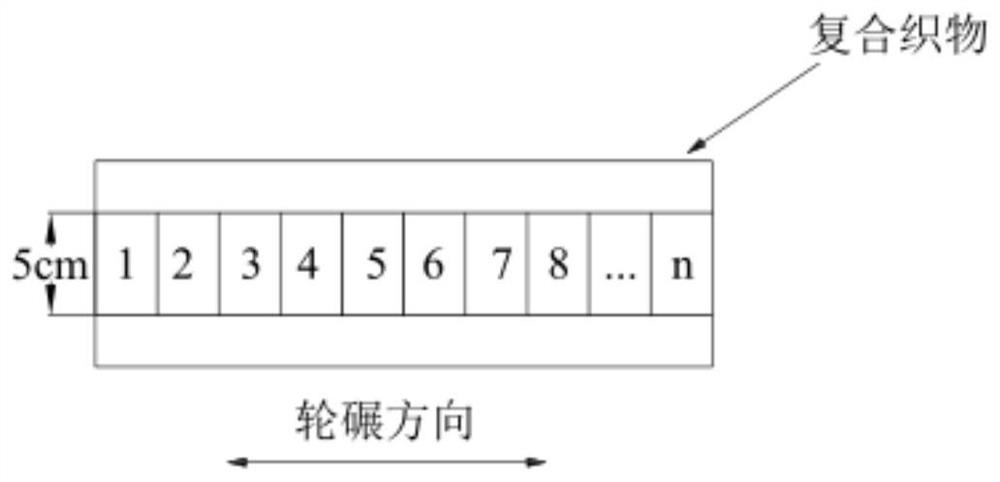

[0023] Aiming at the disadvantages of the prior art, such as high test intensity, large investment, and high subjectivity of evaluation results, the solution of the present invention is to use a special gravel seal sample with an asphalt patch on the bottom, and make the asphalt patch along the There are different thicknesses in the rolling direction of the wheel to simulate different asphalt dosages, so that all oil spill evaluation results within the required asphalt dosage range can be obtained in one test; and the area ratio of the asphalt coverage area on the lower surface of the composite fabric is used as the tested broken The evaluation index of the oil flooding degree of the stone seal layer effectively eliminates the disadvantage of the subjective evaluation results of the traditional test method.

[0024] The technical scheme proposed by the present invention is specifically as follows:

[0025] A method for testing the degree of oil spillage of a gravel seal, compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com