Electric wire sleeve pre-embedded fixing device and fixing method thereof

A fixing device and bushing technology, applied in electrical components and other directions, can solve the problems of easy inclination and deviation, difficult pre-embedding of wire bushings, blocked and other problems, and achieves the effects of easy turnover, convenient disassembly and assembly, and high adjustability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The present invention will be described in detail below with reference to the drawings and specific embodiments.

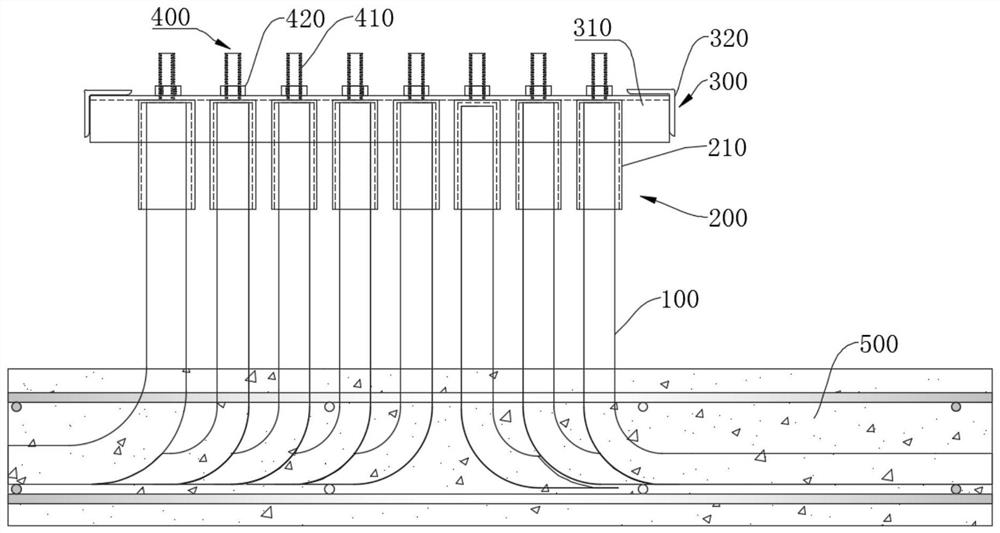

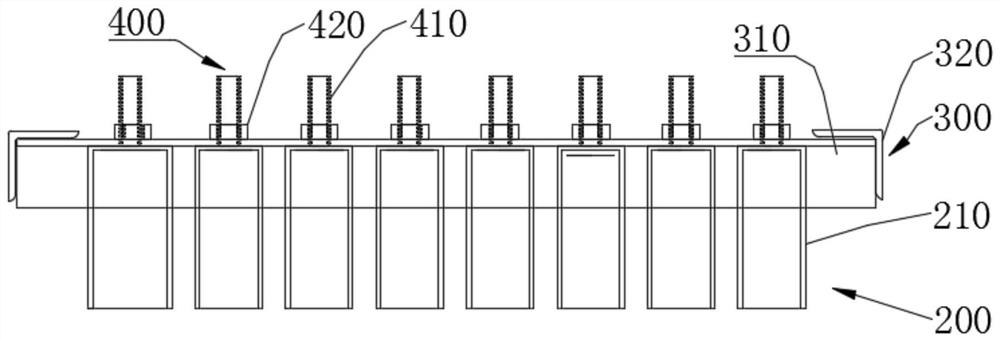

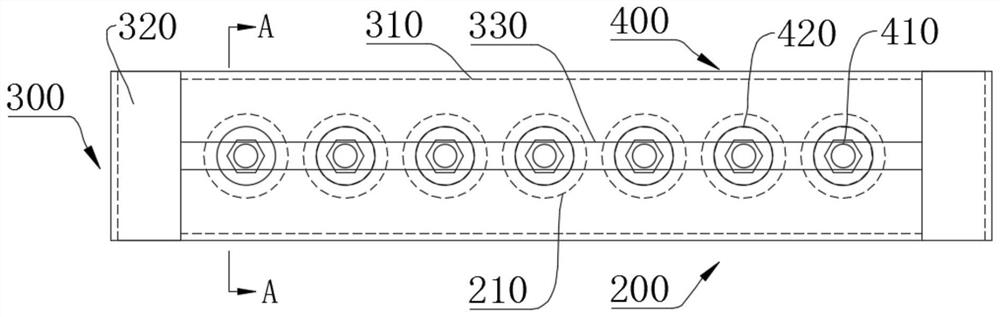

[0035] This embodiment provides a wire casing pre-embedded fixing device, such as Figure 1-4 As shown, it includes a fixing assembly 200 that is used to fix the wire sleeve 100 and is penetrated by the wire sleeve 100 and is arranged side by side with the length axis of the wire sleeve 100; and is used to locate the position of the wire sleeve 100 at the fixing assembly 200 A positioning assembly 300 directly above and coaxially connected with the fixing assembly 200; and a sealing assembly 400 that sequentially penetrates the positioning assembly 300 and the fixing assembly 200 and makes the wire sleeve 100 vertically arranged.

[0036] Further, the fixing assembly 200 includes a plurality of cylindrical columns 210 arranged in parallel. The cylindrical columns 210 have a straight cylindrical structure and their upper end faces are vertically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com