Strong coupling magnetic coupling for micro turbojet engine

A turbojet engine and magnetic coupling technology, which is applied in the direction of machines/engines, electric brakes/clutches, permanent magnet clutches/brakes, etc., can solve the problem of very high machining accuracy and installation accuracy, and uneven force on contact points , uncontrollable vibration and other problems, to achieve the effect of solving large vibration, reducing vibration, and uniform transmission force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

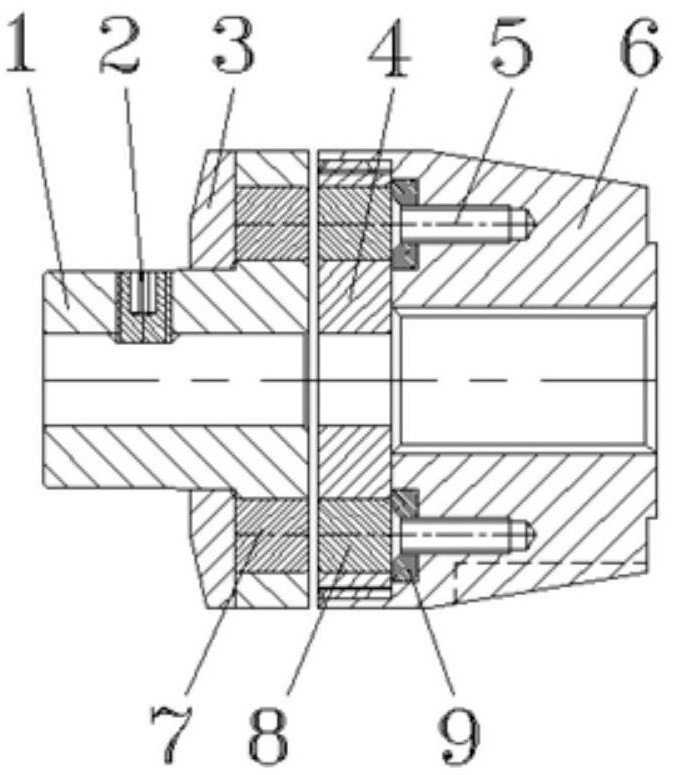

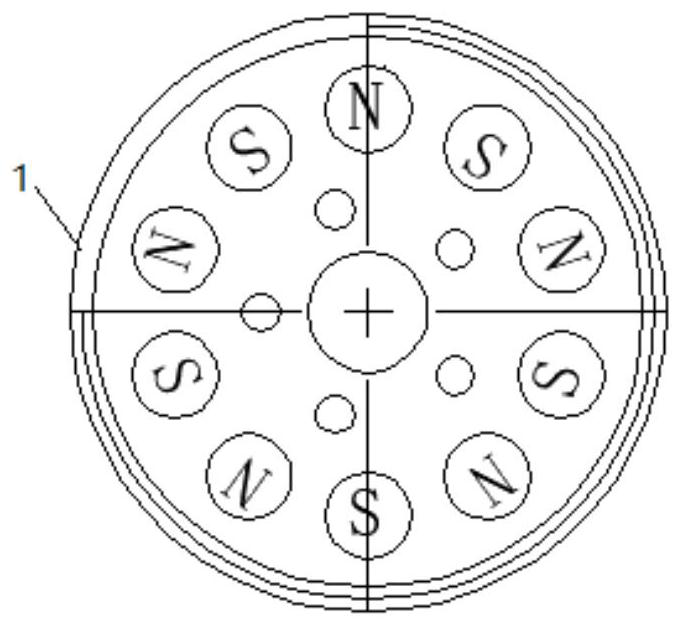

[0017] Example 1, such as figure 1 , figure 2 As shown, a strong coupling magnetic coupling for a miniature turbojet engine, including the coaxial arrangement of the drive shaft of the turbine engine and the rotating shaft of the generator, the connecting end of the rotating shaft of the generator is equipped with a motor coupling Shaft 1, the connecting end of the drive shaft of the turbine engine is equipped with a rotor nut 6, and the rotor nut 6 is connected with a rotor coupling flange 4; the motor coupling 1 and the rotor coupling flange At least two first neodymium boron magnets 7 with alternating magnetic poles are installed on the connecting end surface of 4, and the connecting surface of the rotor coupling flange 4 and the motor coupling 1 is equipped with alternating magnetic poles corresponding to the first neodymium boron magnets 7. The second neodymium boron magnet 8 . The connecting end face of the motor coupling 1 is set corresponding to the connecting end f...

Embodiment 2

[0021] Embodiment 2: Same as Embodiment 1, the difference is that after installation, the centerline of the motor coupling 1 is aligned with the centerline of the rotor nut 6, and the distance between the two intermediate connections is 0.3mm. The first neodymium-boron magnets 7 and the second neodymium-boron magnets 8 are correspondingly installed in eight evenly distributed in the circumferential direction.

Embodiment 3

[0022] Embodiment 3: Same as Embodiment 1, the difference is that after installation, the centerline of the motor coupling 1 is aligned with the centerline of the rotor nut 6, and the distance between the two intermediate connections is 0.5mm. There are 10 first neodymium boron magnets 7 and second neodymium boron magnets 8 that are evenly distributed in the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com