Industrial automation equipment control system based on 5G network

An industrial automation and equipment control technology, which is applied in the direction of transmission systems, instruments, electrical components, etc., can solve the problems of lack of control management, increase the time for maintenance equipment, reduce work efficiency, etc., to improve convenience, convenient and fast data transmission, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Industrial automation is the trend of widely using automatic control and automatic adjustment devices in industrial production to replace manual manipulation of machines and machine systems for processing and production. Industrial automation equipment improves product consistency and saves labor costs through automated operations. However, due to the large number of industrial automation equipment, the staff often lack timely and effective control and management of them. When there is a problem with the equipment or the surrounding environment of the equipment, it is often difficult to find out. Therefore, the present invention provides a 5G network-based industrial automation equipment control system.

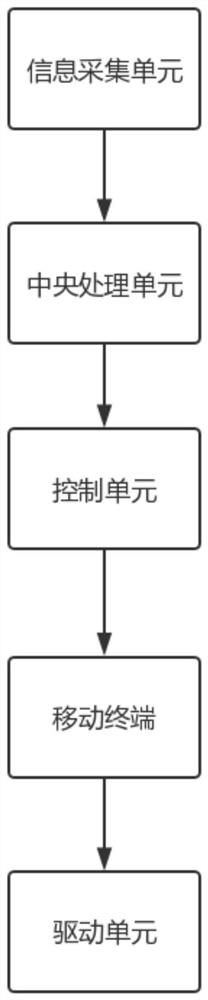

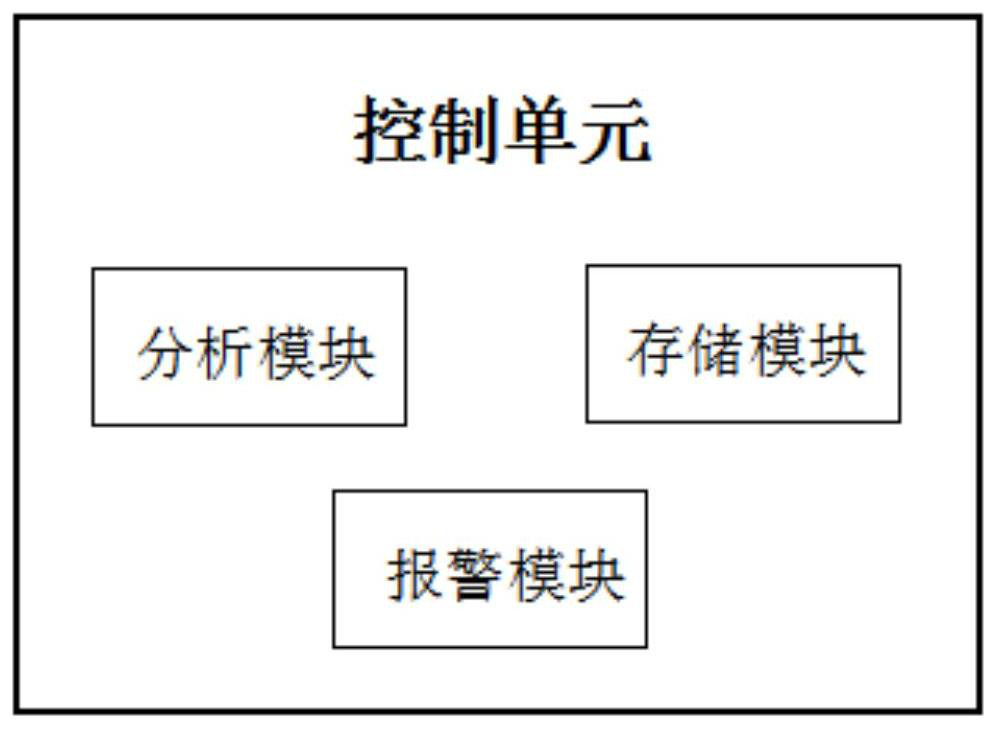

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 3 As shown, a 5G network-based industrial automation equipment control system includes:

[0023] An information collection unit for obtaining rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com