Preparation and application of trinexapac-ethyl emulsion in water

A technology of ester-water emulsion and water-emulsion, which is applied in the field of preparation of trinexapac-ethyl water-emulsion, can solve the problems of complex method, general preparation efficiency, unsuitability for high-efficiency and low-cost industrial production, and achieve simple process and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

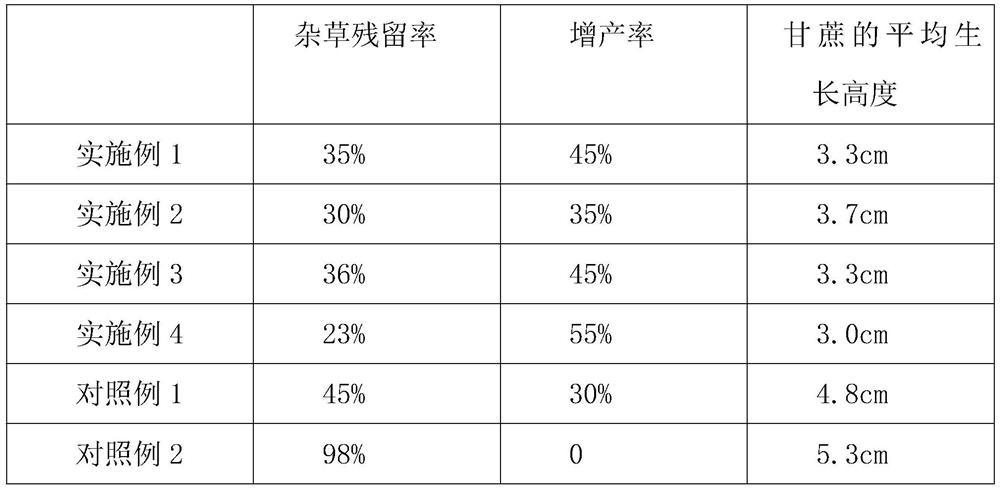

Examples

preparation example Construction

[0031] The preparation method of the trinexapac-ethyl aqueous emulsion comprises the following raw materials in the mass fraction proportion: 12-25% of ethyl 3,5-dioxcyclohexyl carboxylate, 10-28% of cyclopropanecarboxylic acid, and 20% of non-polar organic solvent -30%, organic amine 25-30%, phosphorus trichloride: 8-13%, catalyst: 2-5%.

[0032] The non-polar organic solvent is a mixture of toluene, acetonitrile, dimethylformamide and N,N-dimethylaniline; the organic amine is a mixture of dimethylamine, diethylamine, dibutylamine, trimethylamine and triethylamine .

Embodiment 1

[0034] Raw materials: 15% ethyl 3,5-dioxcyclohexyl carboxylate, 20% cyclopropanecarboxylic acid, 22% non-polar organic solvent, 28% organic amine, 10% phosphorus trichloride, and 5% catalyst.

[0035] Wherein the mass percentage component of non-polar organic solvent is:

[0036] Toluene 50%;

[0037] Acetonitrile 25%;

[0038] Dimethylformamide 11%;

[0039] N,N-Dimethylaniline 14%.

[0040] Wherein the mass percentage of organic amine component is;

[0041] Dimethylamine 35%;

[0042] Diethylamine 20%;

[0043] Dibutylamine 14%;

[0044] Trimethylamine 15%;

[0045] Triethylamine 16%.

[0046] Based on the above raw material ratio, the specific raw material ratio process is:

[0047] The first step: Weigh the raw materials with the required mass fraction ratio in turn for later use;

[0048] The second step: Then add an appropriate amount of ethyl 3,5-dioxocyclohexylcarboxylate and cyclopropanecarboxylic acid into the reaction kettle, and the inside of the reaction...

Embodiment 2

[0053] Raw materials: 20% ethyl 3,5-dioxcyclohexyl carboxylate, 15% cyclopropanecarboxylic acid, 25% non-polar organic solvent, 25% organic amine, 10% phosphorus trichloride, and 5% catalyst.

[0054] Wherein the mass percentage component of non-polar organic solvent is:

[0055] Toluene 45%;

[0056] Acetonitrile 30%;

[0057] Dimethylformamide 11%;

[0058] N,N-Dimethylaniline 14%.

[0059] Wherein the mass percentage of organic amine component is;

[0060] Dimethylamine 35%;

[0061] Diethylamine 20%;

[0062] Dibutylamine 14%;

[0063] Trimethylamine 15%;

[0064] Triethylamine 16%.

[0065]Based on the above raw material ratio, the specific raw material ratio process is roughly the same as that in Example 1, wherein the molar mass ratio of ethyl 3,5-dioxcyclohexylcarboxylate to cyclopropanecarboxylic acid in the reactor is 1:0.75 ; The molar mass ratio of ethyl 3,5-dioxcyclohexylcarboxylate to non-polar organic solvent is 1:1.25; the molar mass ratio of ethyl 3,5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap